In-situ rush-repair and leakage-repair method for rubber dam bags and repair device

A technology of rubber dam bag and connecting column, applied in water conservancy engineering, marine engineering, construction and other directions, can solve the problem of impossible sticking and repairing construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

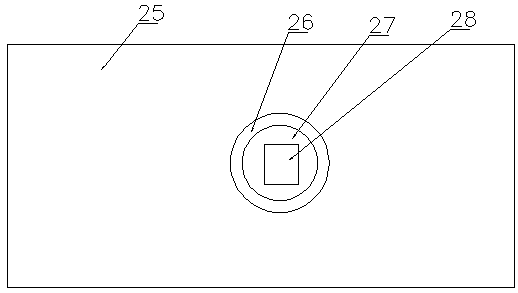

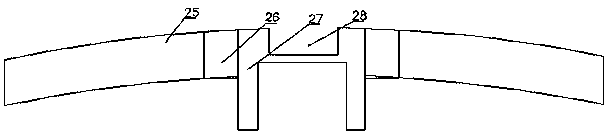

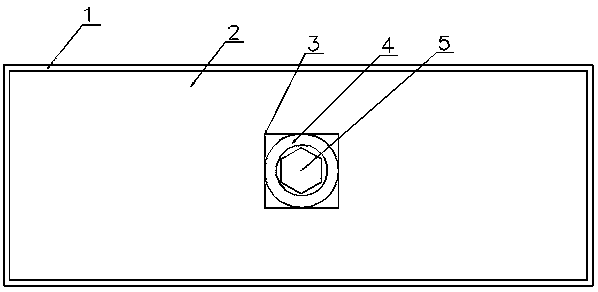

[0039] Embodiment one: if Figure 1-9 As shown, a rubber dam bag on-site emergency repair and repair device includes an inner base 1 and a connecting column arranged on the inner base. Firmware 8, the fastener is used to press the pressure plate tightly, the clamping operating mechanism is provided in the connecting column, which is convenient for on-site installation of the repair device, and the clamping operating mechanism includes a positioning rod that matches the through hole in the connecting column and a handle arranged on the positioning rod, the positioning rod is a hollow structure. The through hole 5 in the connecting column plays the role of temporary exhaust. According to the bag pressure in the rubber dam on site, if the water storage level is not high, the pressure in the rubber dam bag can be kept constant, and the air supply can be continued to prevent the water storage level from suddenly falling. If the pressure releases and falls, it will cause harm to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com