Edge sealing formwork corner exhausting device for slab-type ballastless track self-compacting concrete

A technology of self-compacting concrete and slab-type ballastless track, which is applied in the direction of track, track laying, track maintenance, etc., and can solve the problems of poor exhaust effect, inability to eliminate voids and foam layers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

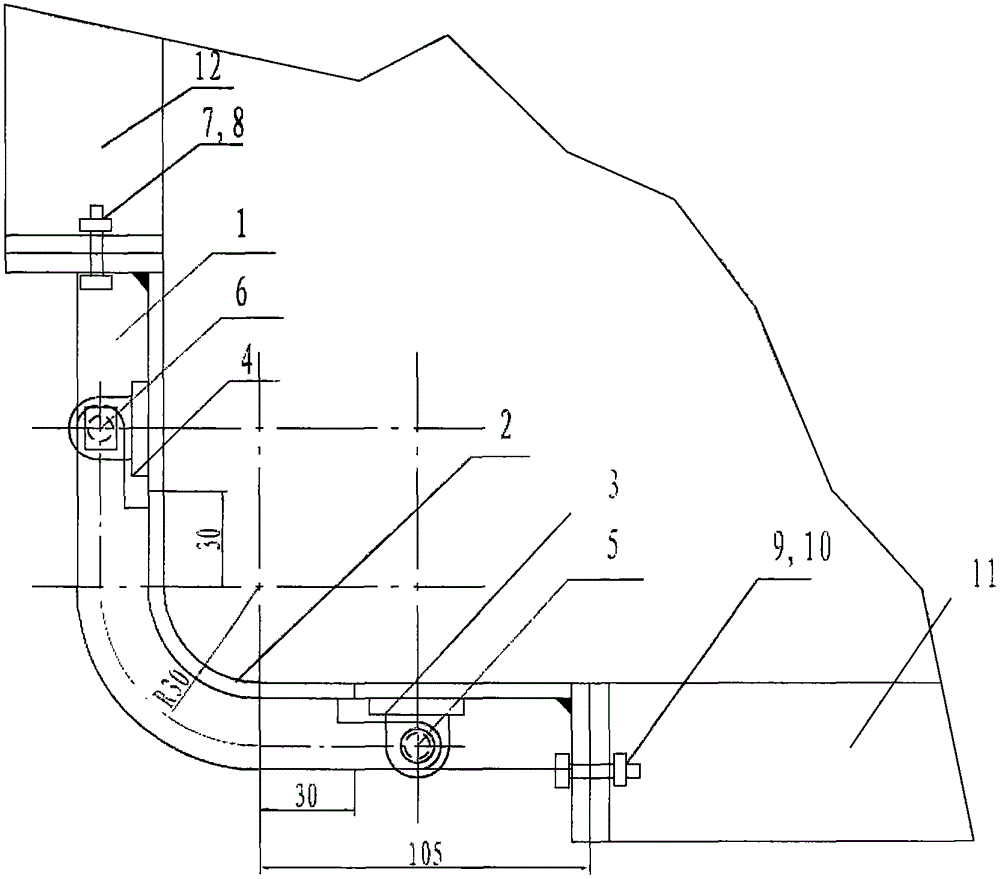

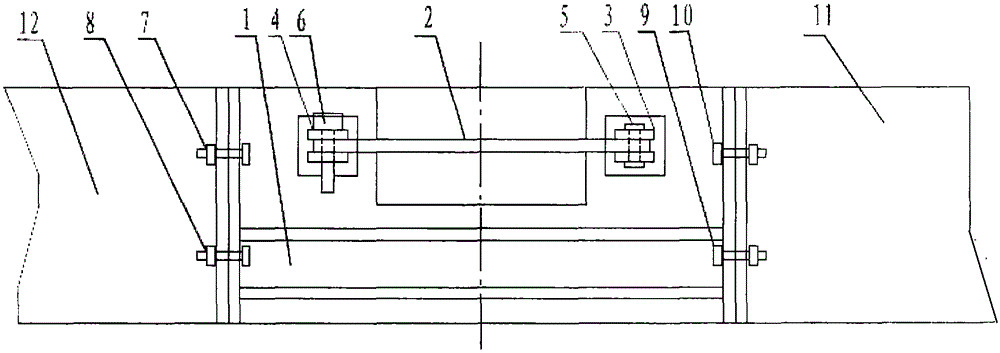

[0013] The installation and use method of the present invention will be described below in conjunction with the accompanying drawings and specific embodiments:

[0014] figure 1 with figure 2 They are the top view and side view of the angled edge sealing exhaust device for CRTSIII type ballastless track self-compacting concrete, which consists of angled formwork 1, movable door 2, connectors 3-4, connecting rod 5, latch 6, and bolts 7 to 10 components. Before the construction of self-compacting concrete, paste a layer of high-density non-woven fabric on the inside of the angle formwork 1 and the movable door 2, and then connect the two ends of the angle formwork 1 to the self-compacting concrete through bolts 7-8 and 9-10 respectively. The straight section templates 12 and 11 of the layers are connected and fixed. During self-compacting concrete construction, when the self-compacting concrete flows in the track slab cavity, the dodge door 2 is opened along the connecting r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Opening height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com