Quick-build composite wall board

A technology of wall panels and clips, applied in the direction of building components, buildings, building structures, etc., can solve the problems of inconvenient installation and disassembly, poor sealing effect, single assembly method, etc., to achieve smooth bonding and stable wall panels , Neat and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

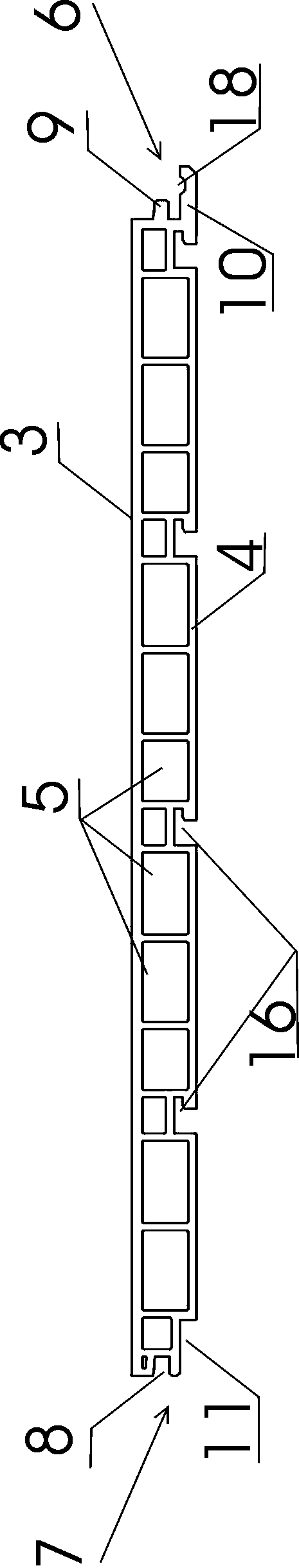

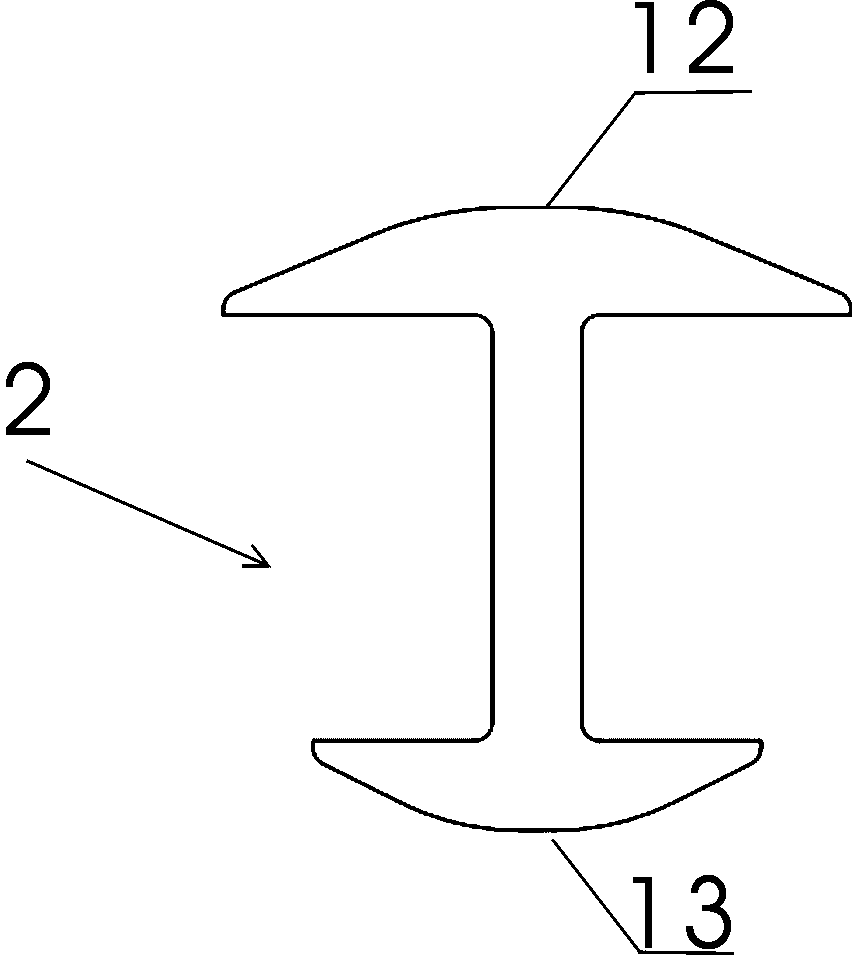

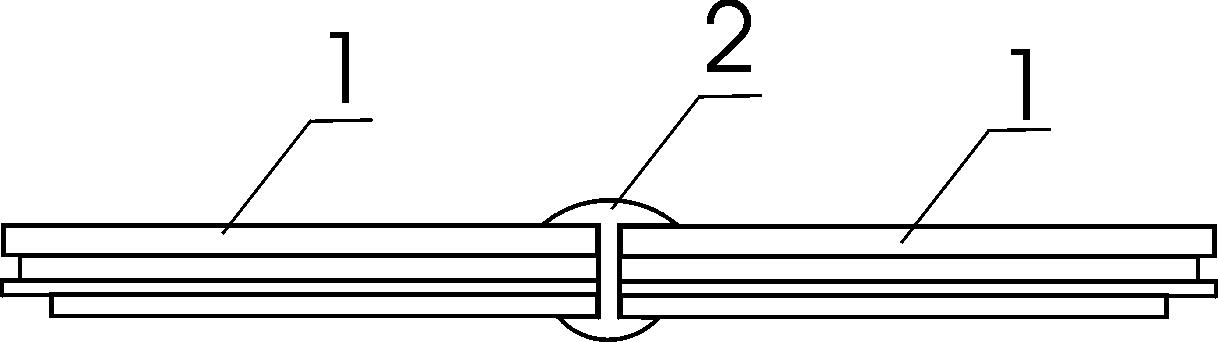

Embodiment 1

[0021] Embodiment 1: The quick-build composite wall panel of the present invention can be directly installed on the building wall. The wall panels 1 and the clips 2 are made of wood-plastic materials, have excellent anti-corrosion, waterproof, and anti-moth-eaten properties, and are durable in an outdoor environment. The wall panel 1 is made with a mold and is integrally formed. There is a regular hollow space 5 between the front 3 and the back 4 of the wall panel, which not only saves materials but also ensures sufficient strength. The lengthening of the wall panel is extended by the male and female fittings of the special structure of the male connector and the female connector. The slot 8 Matching with the clip 9, the L-shaped bayonet 11 matches the card 10, and the connection is tight and firm. The groove 18 on the male connector card 10 is used to screw the wall panel to the wall frame. The connection method starts from the wall panel. No fixing screws can be seen from t...

Embodiment 2

[0022] Embodiment 2: If the building has relatively high requirements on the wall panels and wants to be more stable and durable, the method of this embodiment can be used. Increase the use of the fasteners 14, specifically: fix the fasteners 14 on the wall frame (connect the fasteners to the wall with screws through the fixing holes 17 on the fasteners), and then pass the wall panel 1 through the back of the wall panel. The hanging slot 16 of the hook is clamped on the hook 15 of the fastener for connection and fixation, and the rest is the same as that of the first embodiment; in this way, the wall panel is stable and smooth, and the connection is more firm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com