Method for enhancing permeability improvement of soft coal body containing gas by joint action of shock waves and acidification

A joint action and shock wave technology, which is applied in the direction of gas discharge, mining fluid, earthwork drilling, etc., can solve problems such as secondary disasters, variable anti-reflection effects, and water pollution of fracturing fluids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

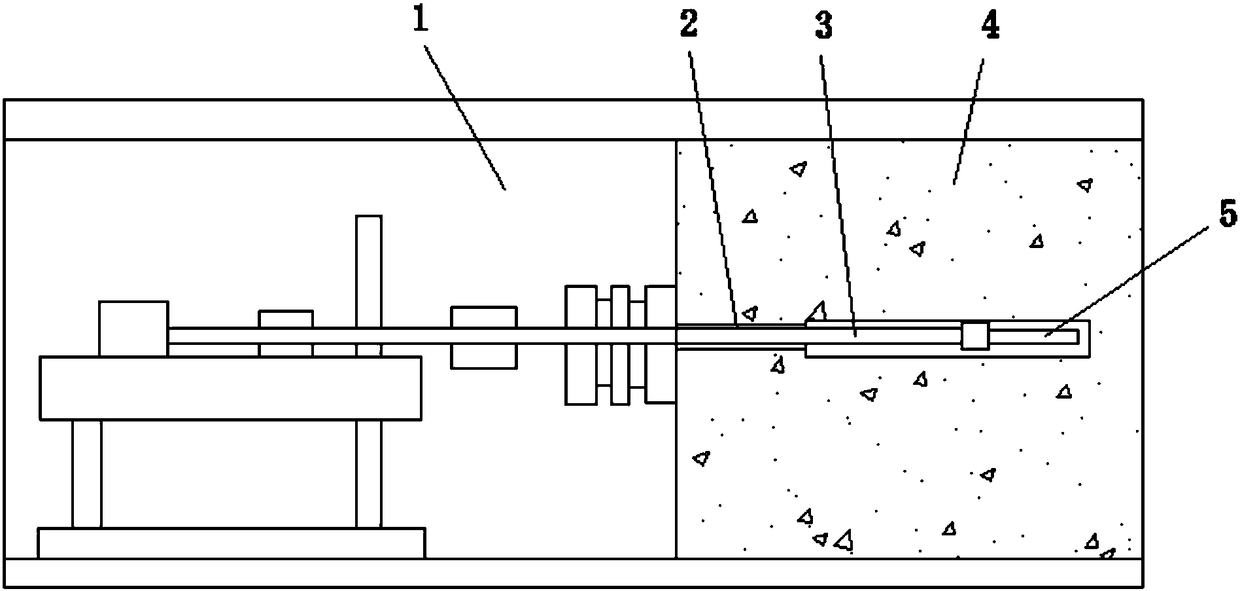

[0030] Example 1: Method for strengthening and anti-reflection of gas-containing soft coal with combined action of shock wave and acidification

[0031] The method for strengthening and anti-reflection of gas-containing soft coal with the combined effect of shock wave and acidification of this embodiment includes the following steps:

[0032] (1) Arrange a number of drill holes in the trench along the working face, the drill holes are horizontal holes along the coal seam; the hole diameter of the drill holes is 108mm, the depth is 50m, the distance from the bottom plate is 1.5m, and the distance between adjacent holes is 2m;

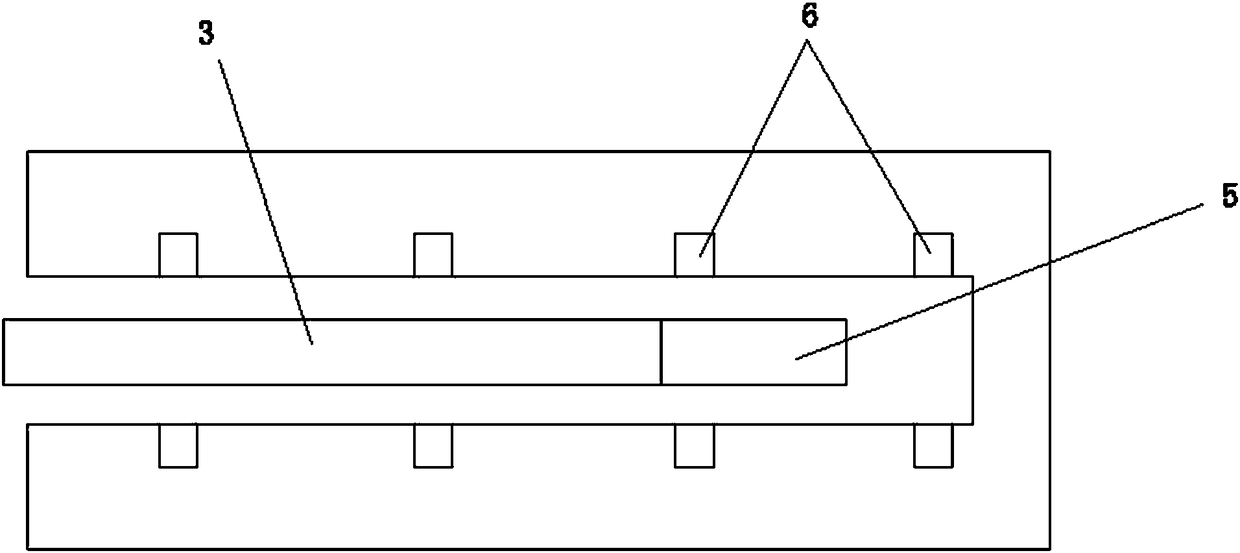

[0033] (2) Use the drill rod to transport the shock wave generator to the bottom of the borehole, then seal the hole, and then fill the borehole with water;

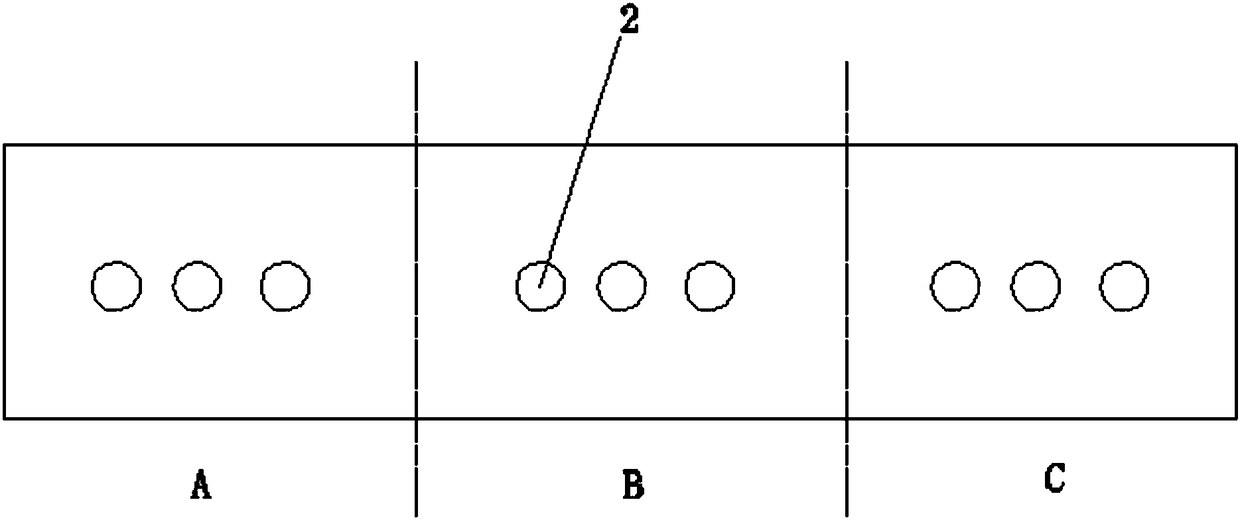

[0034] (3) Select the shock wave strengthening area in the borehole, and move the shock wave generator through the joystick, so that the shock wave generator will gradually open and act in each shock wave s...

Embodiment 2

[0039] Example 2: Example and evaluation of enhanced anti-reflection method for gas-containing soft coal with combined action of shock wave and acidification

[0040] The 1296 fully mechanized mining face of a mine is located in the 9th coal seam 2 mining area, with a strike length of 642m and a slope length of 171m. The thickness of the coal seam is 2.5m, the direction of the coal seam is 25-35°, the average inclination of the coal seam is 8°, the recoverable index is 1, and the coal seam is stable; the old roof is dark gray siltstone with a thickness of 2.7m, and the direct roof is dark black mudstone with a thickness of 2.2 m; The direct bottom is brown-grey fine sandstone with a thickness of 2.5m, while the old bottom is fine sandstone with a thickness of 4.6m. The coal dust explosion coefficient is 38.72%. Long spontaneous combustion period; coal bulk density is 1.4t / m 3 ; The working face recovery rate is 95%; the working face mining height is 2.2m, and the daily advance i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com