Chemical composition of acidified solution for improving permeability of coal seam

A permeability and solution technology, applied in the field of coalbed methane and chemical applications, can solve the problems of manpower, material resources, financial resources, difficulty in extraction, change the conductivity of coal seams, etc., to suppress the mass transfer rate, prolong the reaction time, The effect of increasing the effective range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Hydrochloric acid, hydrofluoric acid, acidification retarder, acidification corrosion inhibitor, iron ion stabilizer, anti-swelling agent and water are used to prepare a solution. The weight percentages of each component in the solution are: hydrochloric acid, hydrofluoric acid, acidification retarder, acidification corrosion inhibitor, iron ion stabilizer, anti-swelling agent are respectively 9%, 2%, 2.5%, 1.5%, 0.3%, 2%; the balance is water. Mix the acid solution slowly at room temperature, shake well and let stand.

Embodiment 2

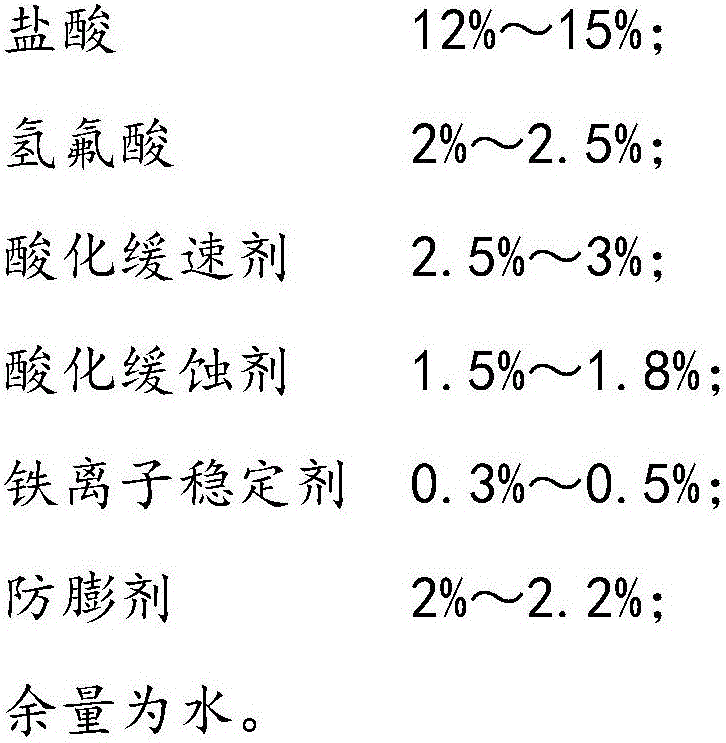

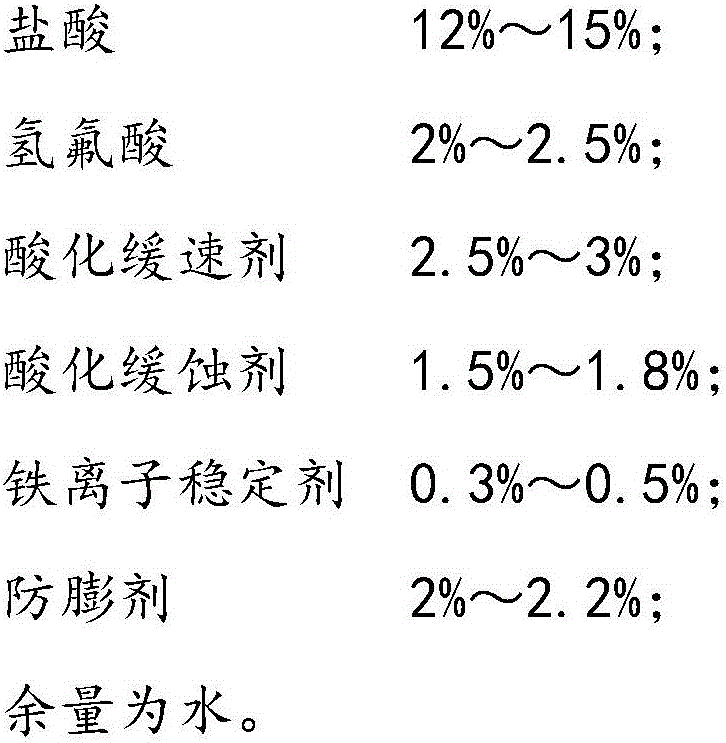

[0030] Hydrochloric acid, hydrofluoric acid, acidification retarder, acidification corrosion inhibitor, iron ion stabilizer, anti-swelling agent and water are used to prepare a solution. The percentage by weight of each component in the solution is: hydrochloric acid, hydrofluoric acid, acidification retarder, acidification corrosion inhibitor, iron ion stabilizer, anti-swelling agent are respectively 12%, 2%, 2.5%, 1.5%, 0.3%, 2%; the balance is water. Mix the acid solution slowly at room temperature, shake well and let stand.

Embodiment 3

[0032] Hydrochloric acid, hydrofluoric acid, acidification retarder, acidification corrosion inhibitor, iron ion stabilizer, anti-swelling agent and water are used to prepare a solution. The percentage by weight of each component in the solution is: hydrochloric acid, hydrofluoric acid, acidification retarder, acidification corrosion inhibitor, iron ion stabilizer, anti-swelling agent are respectively 15%, 2%, 2.5%, 1.5%, 0.3%, 2%; the balance is water. Mix the acid solution slowly at room temperature, shake well and let stand.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com