Digging method of ore pass

A technology for sliding mine shafts and vertical shafts, which is applied in the field of mine seam mining. It can solve the problems of poor safety, high cost, and long excavation time of sliding mine shafts, and achieve the effects of safe excavation process, reducing the time for going up and down the working surface, and avoiding poor ventilation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

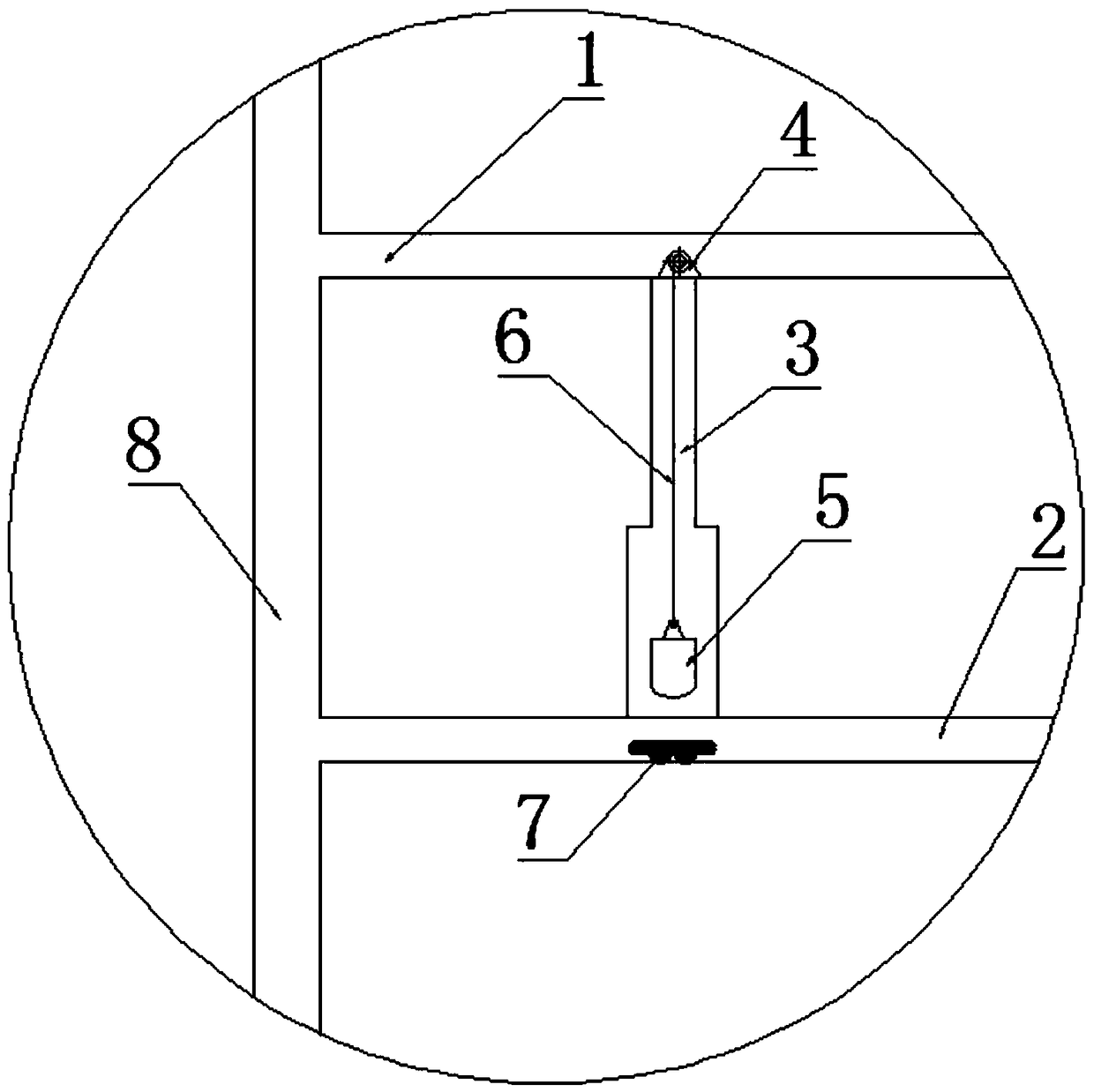

[0017] A kind of excavation method of sliding mine shaft (referring to figure 1 ), comprising the main shaft 8 and the up and down adjacent upper layer roadway 1 and the lower layer roadway 2 communicated with the main shaft 8, through the following steps to realize the forming of the mine shaft:

[0018] The first step is to open the hole by down-the-hole drilling: use the down-the-hole drill to drill a central hole 3 from the lower roadway 2 to the upper roadway 1;

[0019] The second step is to install the hanging cage: a winch 4 is set in the upper layer roadway 1, the rope 6 of the winch 4 passes through the center hole 3, hangs in the lower layer roadway 2, and the hanging cage 5 is installed at the end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com