High-speed train brake disc-wheel disc

A technology for high-speed trains and brake discs, applied in the direction of brake discs, brake types, brake components, etc., can solve problems that affect the safety of high-speed trains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing:

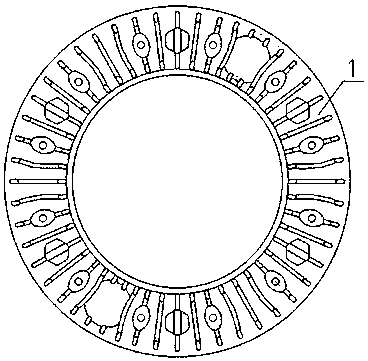

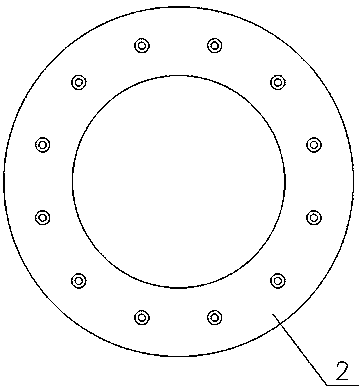

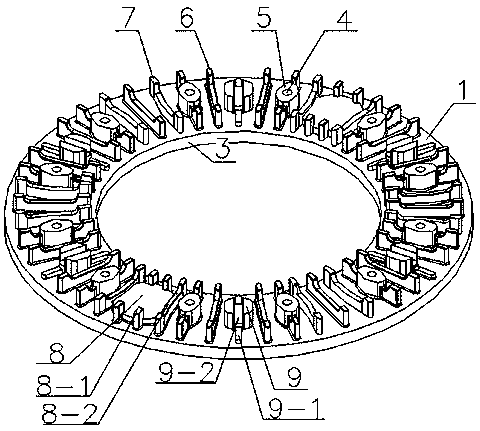

[0012] Such as figure 1 As shown, the present invention relates to a high-speed train brake disc-wheel disc, comprising a brake disc body 1, a brake friction surface 2, a center positioning hole 3, uniformly distributed mounting holes 4, a reinforcing boss 5, a first radial Plate-shaped cooling ribs 6 , second radial fan-shaped cooling ribs transition balance boss 7 , third radial plate-shaped fan-shaped combined cooling ribs 8 , transition balance boss 9 . It is characterized in that: the central positioning hole 3 of the high-speed train brake disc body 1 is positioned on the brake assembly device, connected by bolts through the uniformly distributed installation holes 4, and the uniformly distributed installation holes 4 are distributed on the reinforcing boss 5. The heat generated during the friction process of the braking friction surface 2 is dissipated through the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com