Method of deep maintenance of air conditioner internal unit

A technology for an air-conditioning internal unit and a steam engine, which is applied in air-conditioning systems, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as threats to the health of users, difficulty in cleaning microorganisms completely, and difficulty in cleaning bacteria in exchangers, etc. Ensuring health, improving cleanliness, reducing respiratory infections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

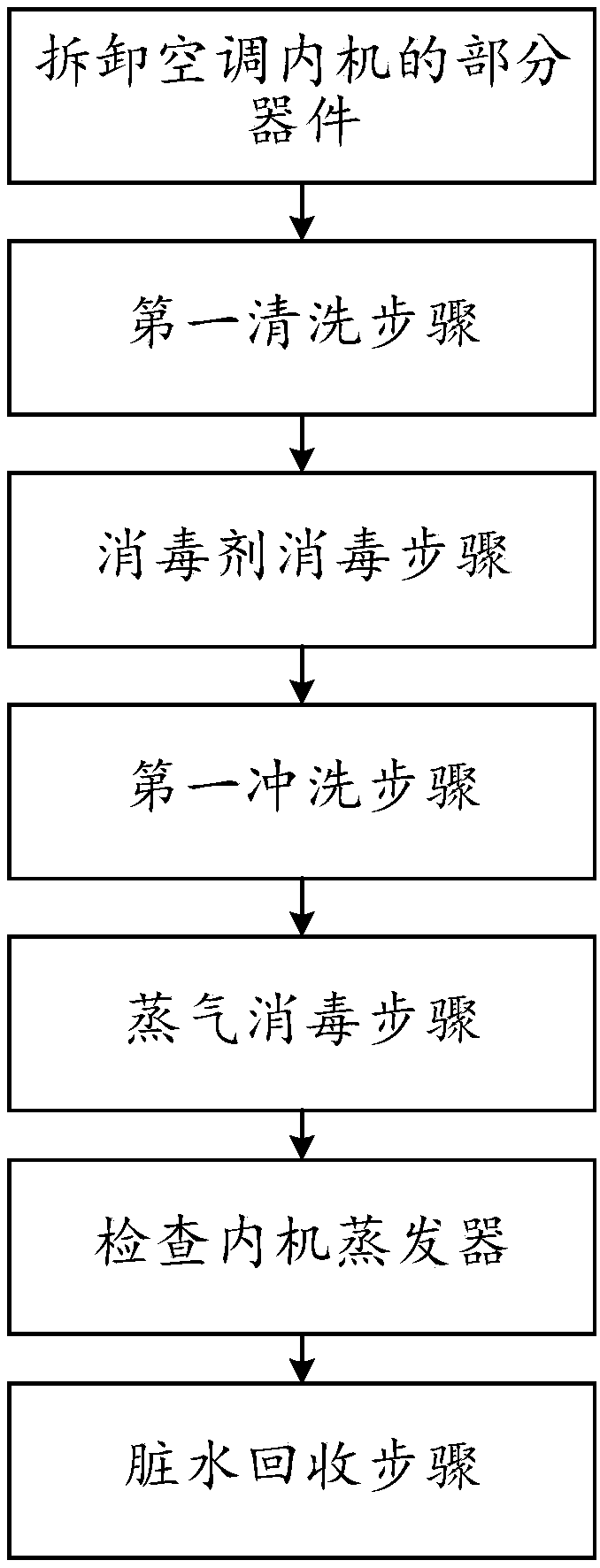

[0051] The first embodiment of the present invention provides a maintenance method for an air conditioner internal unit, combining figure 1 Let's see, including the following steps:

[0052] Disassembly steps, remove the air outlet blades, return air blades and filter screen of the air conditioner internal unit;

[0053] The first cleaning step is to clean the evaporator of the internal unit with an air conditioner cleaner;

[0054] Disinfectant disinfection step, spraying disinfectant on the surface of the internal unit evaporator for disinfection;

[0055] The first flushing step is to flush the evaporator of the internal unit with water;

[0056] In the steam disinfection step, use a steam engine to sterilize the evaporator of the internal machine at high temperature;

[0057] The dirty water recovery step is to recover the sewage produced in the first cleaning step and the first flushing step.

[0058]The function of the air conditioner evaporator is to use the liquid ...

no. 2 approach

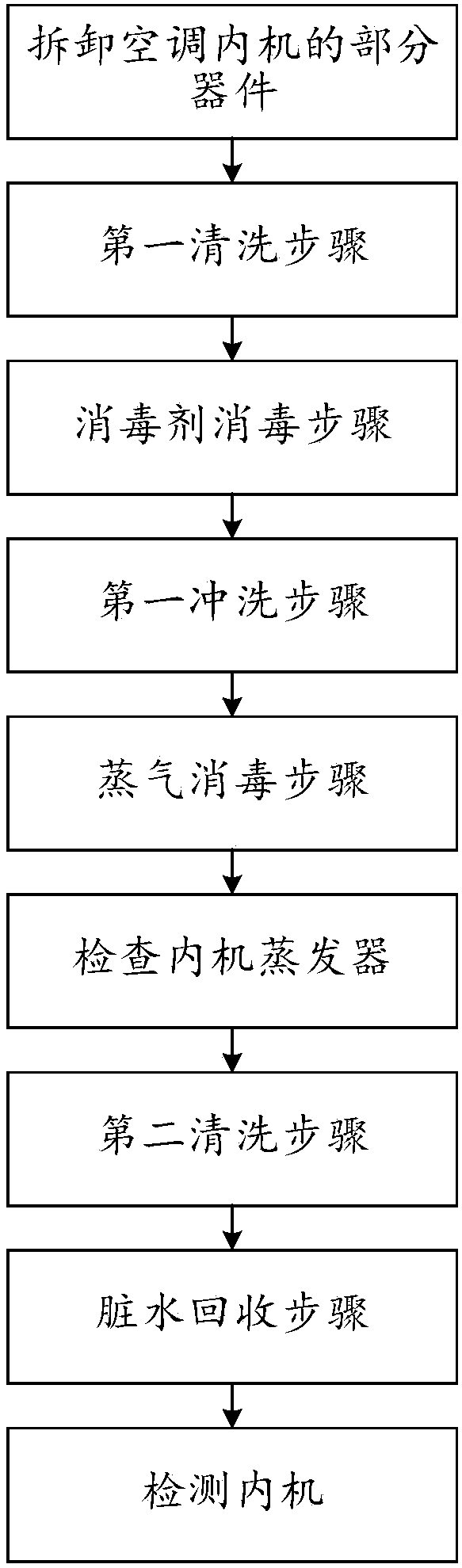

[0077] The second embodiment of the present invention provides a method for maintaining an air conditioner indoor unit. The second embodiment of the present invention is a further improvement on the first embodiment. The main improvement is that the combination figure 2 , image 3 From the point of view, the maintenance method of the air conditioner indoor unit also includes the following steps:

[0078] The second cleaning step is to clean the removed air outlet blades, return air blades and filter screen;

[0079] In the installation step, install the cleaned air outlet blades, return air blades and filter screens on the air conditioner inner unit.

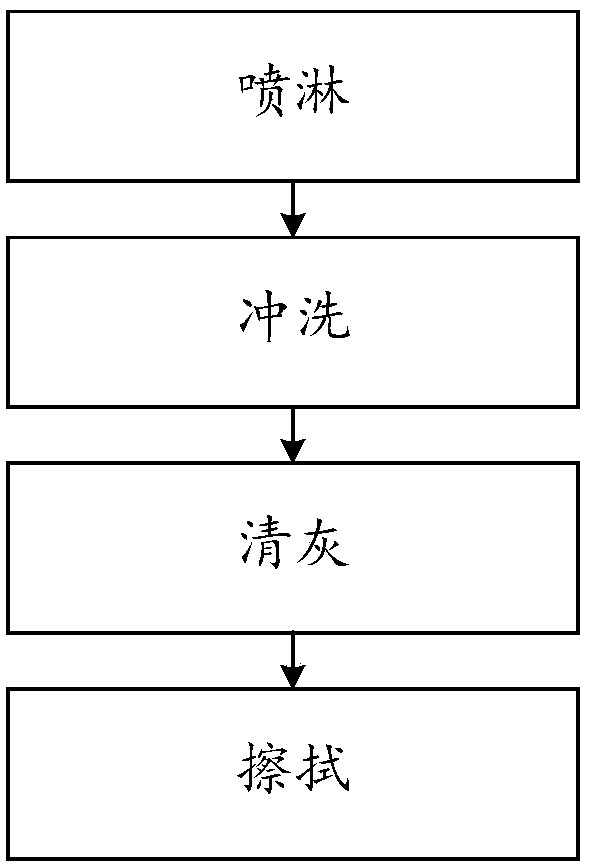

[0080] In the second cleaning step, the following sub-steps are included:

[0081] The handling step is to move the removed air outlet blade, return air blade and filter to the shower room;

[0082] The second washing step is to wash the air outlet blades, return air blades and filter screen;

[0083] In the dust cleaning s...

no. 3 approach

[0096] The third embodiment of the present invention provides a maintenance method for an air conditioner indoor unit. The third embodiment of the present invention is a further improvement on the first embodiment and the second embodiment. The main improvements are as follows:

[0097] In the cleaning step and / or the flushing step, a cleaning pump is used together with a water gun for flushing.

[0098] In the cleaning step and / or flushing step, the water outlet pressure of the water gun is 4kg to 8kg.

[0099] In the cleaning step and / or flushing step, the water outlet pressure of the water gun is 5kg to 6kg.

[0100] Cleaning with a cleaning pump and a water gun can use the pressure of water to wash away strong adhesion stains and foam during cleaning. When cleaning with a water gun, it is easy to clean some difficult-to-clean parts

[0101] In the cleaning step and / or rinsing step, since the structural strength of each device is different, considering the protection of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com