Turbine machinery cae integration platform based on unified management of knowledge base data

A turbomachinery, integrated platform technology, applied in special data processing applications, geometric CAD, design optimization/simulation, etc., can solve the problems of low intelligence, poor reliability, low degree of specialization, etc., to ensure design accuracy and reliability, avoid data distortion problems, and ensure the effect of single data management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

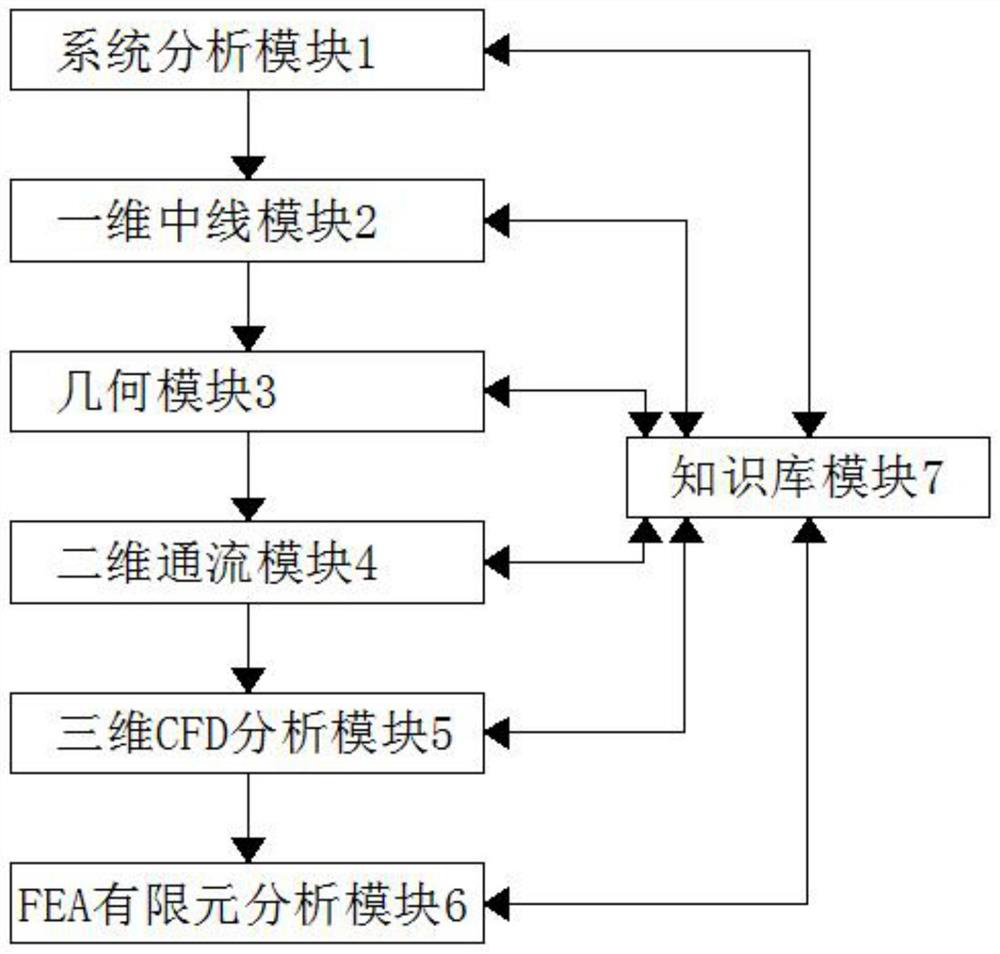

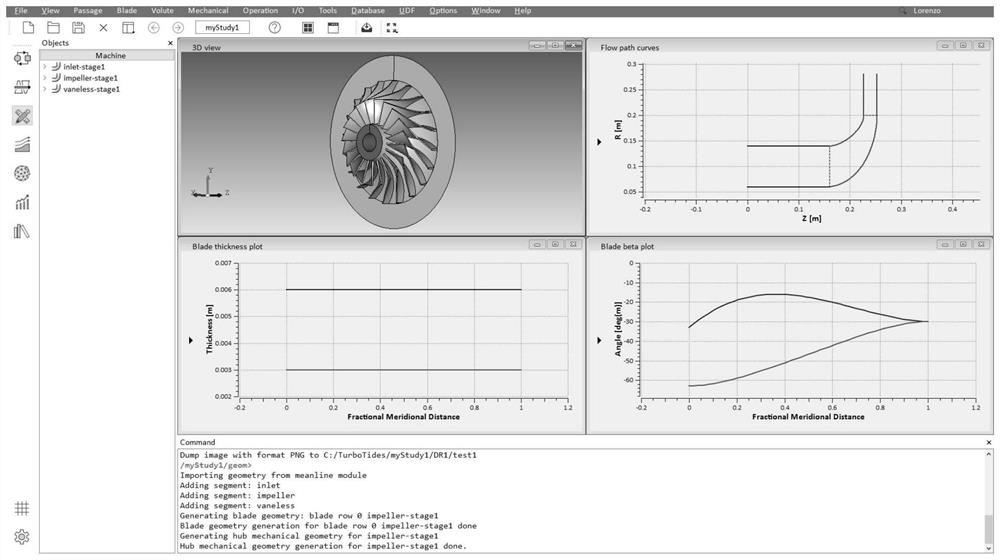

[0063] refer to Figure 2-10

[0064] (1) Enter the system analysis module 1, specify the working directory and the name of the calculation example, select the cycle analysis type (such as multi-stage compression cycle), set the parameters of each component and design or analyze the thermal constraints of the operating point, run the solver, and calculate After the completion, check the thermodynamic parameters of each component, and provide thermodynamic parameters such as compressor inlet and outlet pressure and temperature for the subsequent one-dimensional centerline design and analysis;

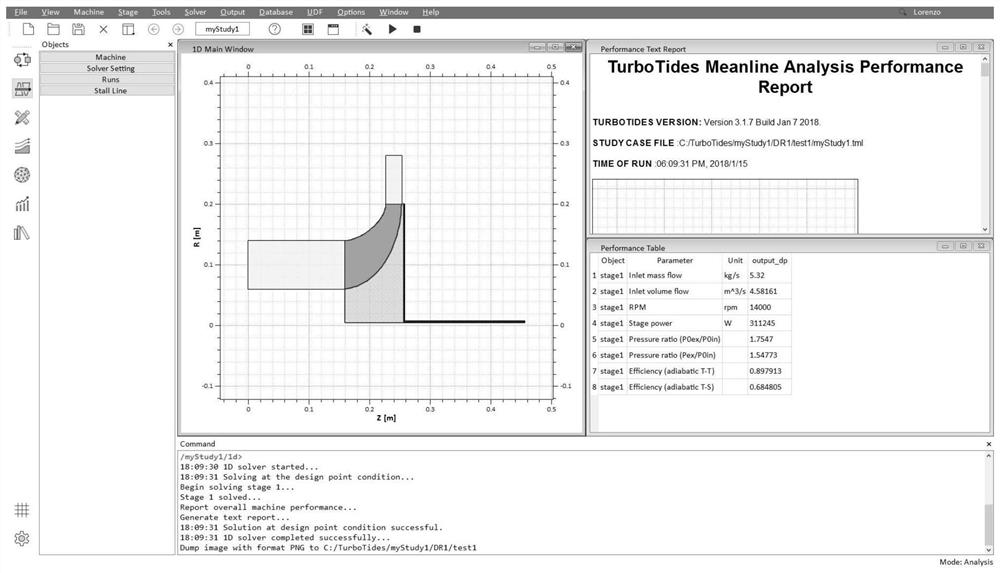

[0065] (2) After the system analysis is completed, enter the one-dimensional centerline module 2, and use the design guide to complete the one-dimensional centerline design or analysis setting of the impeller, and some of the thermal conditions used are directly transferred from the system analysis module 1, without manual input , run the solver, after the calculation is completed, you ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com