Fuel cell hybrid power mobile welding robot energy management method

A welding robot, fuel cell technology, applied in current collectors, electric vehicles, battery circuit devices, etc., can solve the problems of long single charging time, short service life, large volume and weight, etc. The effect of rapid changes and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

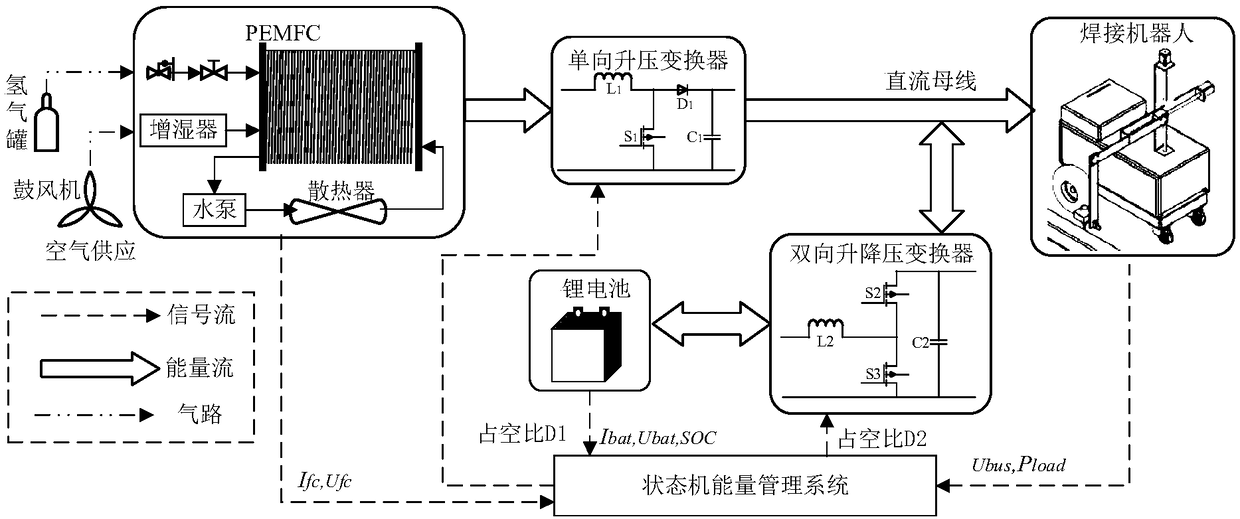

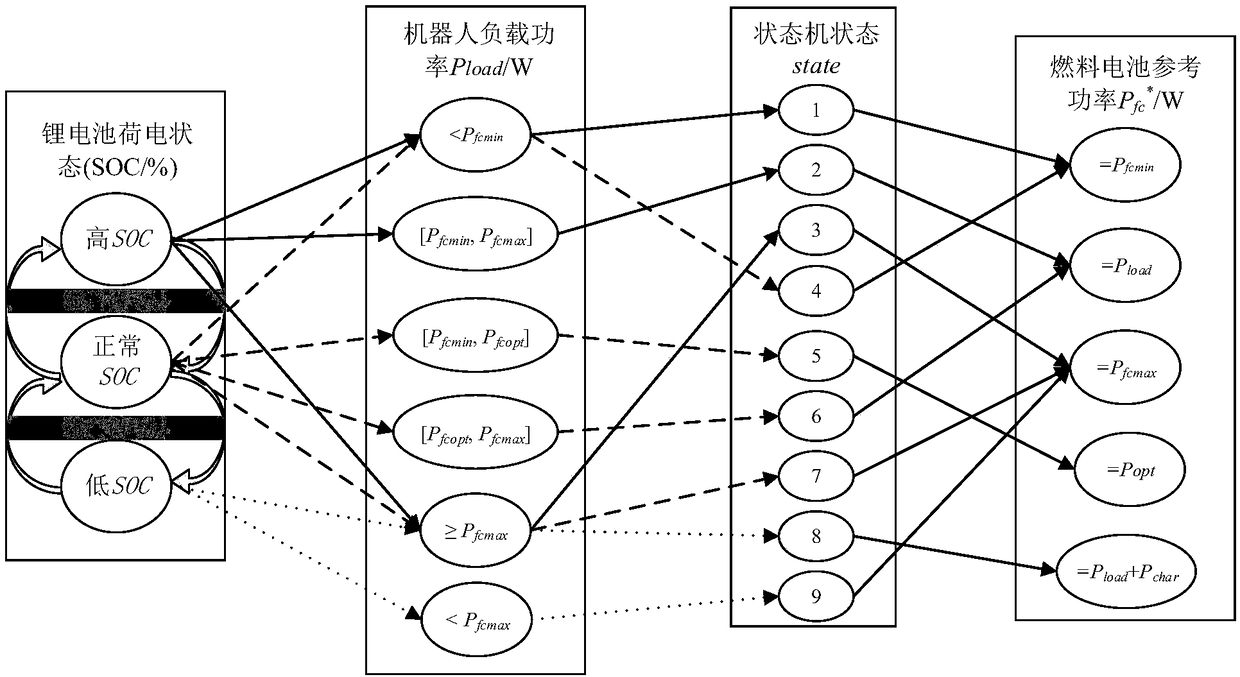

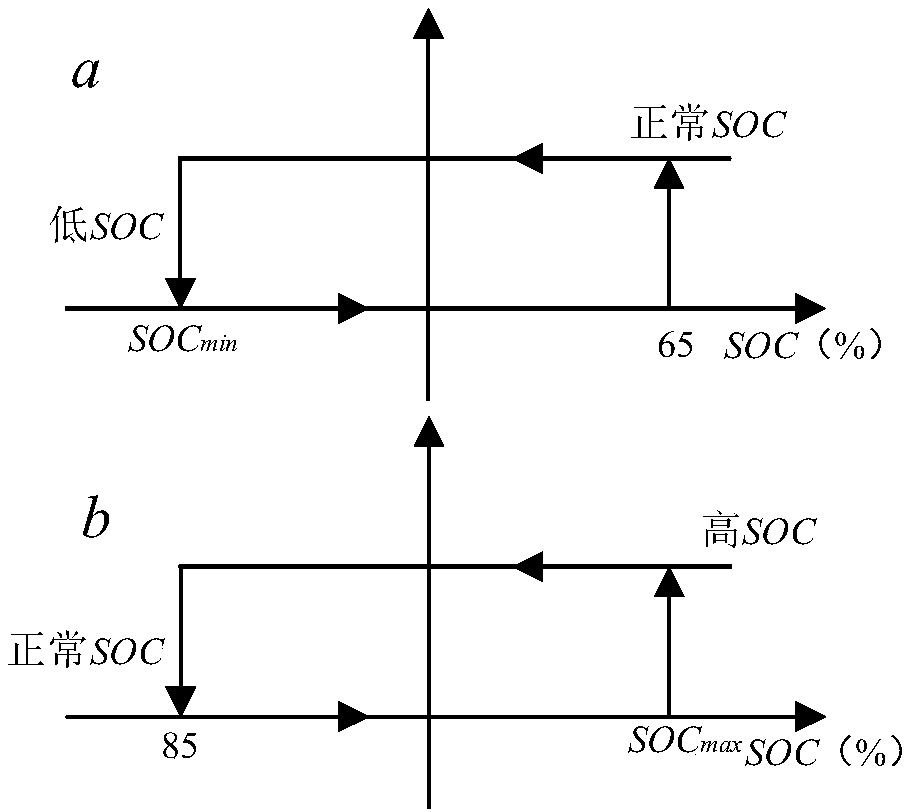

[0048] Such as figure 1 As shown, a mobile welding robot based on fuel cell hybrid power includes a mobile welding robot body, a robot drive controller, and a power supply. The power supply supplies power to the robot drive controller with a 24V DC voltage. The welding robot body performs operation control, and the power supply mainly includes main power supply, auxiliary power supply and energy management unit. The main power supply is a proton exchange membrane fuel cell, and the auxiliary power supply is a lithium battery. The output end of the fuel cell is electrically connected to the DC bus through a unidirectional step-up DC / DC converter, and the output end of the lithium battery is electrically connected to the DC bus through a bidirectional step-up DC / DC converter. Connected to the DC bus, the energy management unit is respectively connected to the mobile welding robot, fuel cell, lithium battery and single / bidirectional DC / DC converter. The energy management unit de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com