Pure electric vehicle drive motor

A pure electric vehicle, driving motor technology, applied in the direction of electric vehicles, motors, electric components, etc., can solve the problems of motor damage, can not meet the needs of customers, does not have buffer protection, etc., to achieve convenient operation, simple structure, easy to install and the effect of disassembly and repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

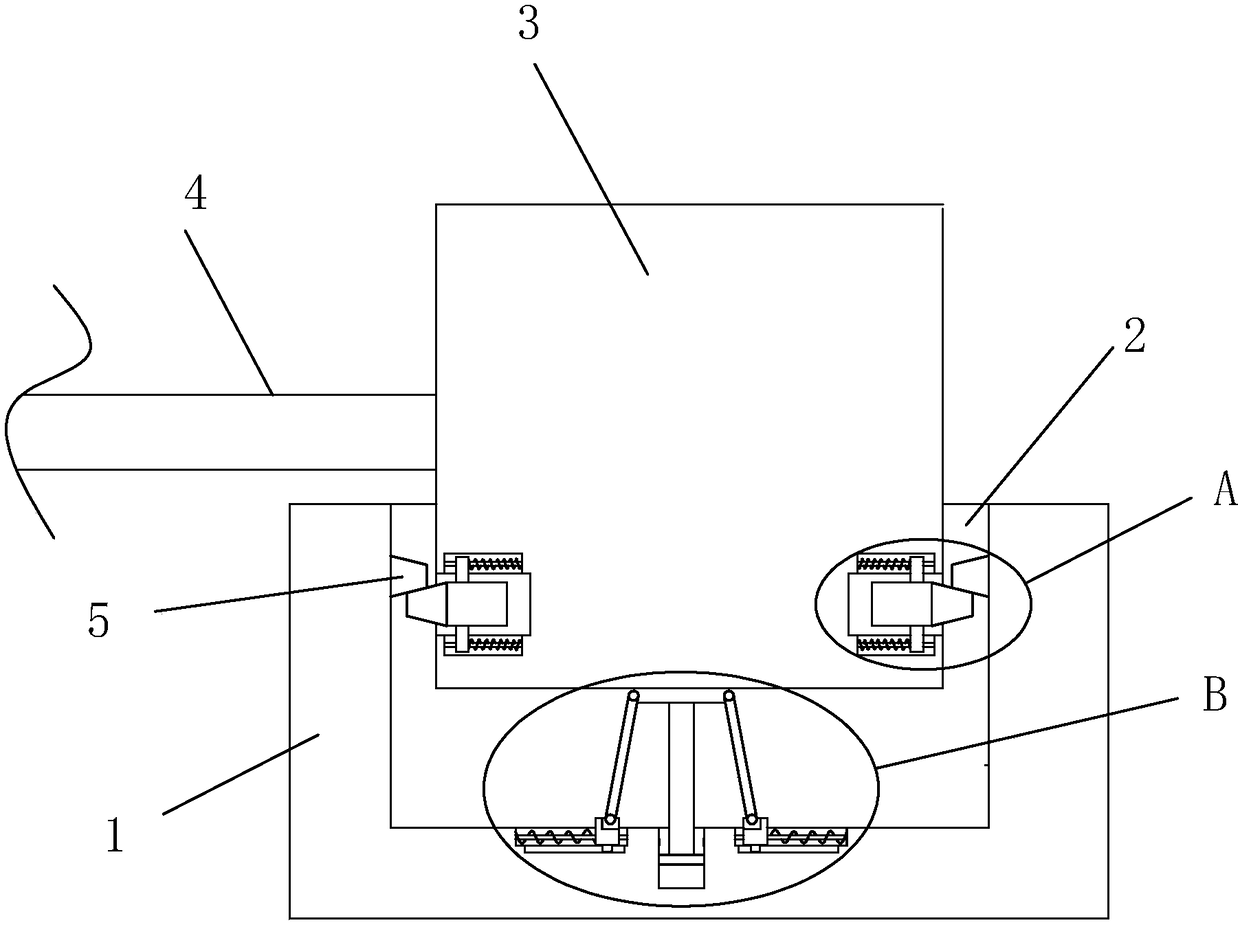

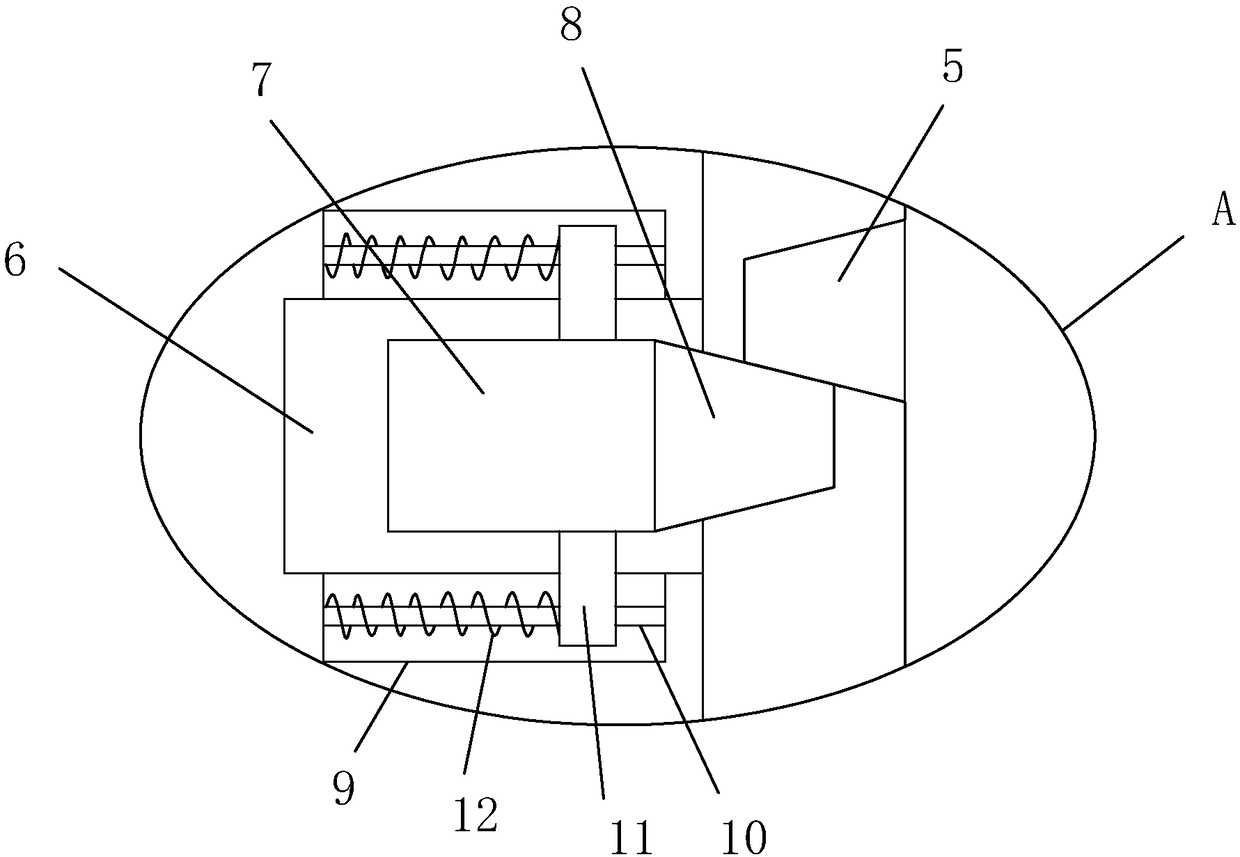

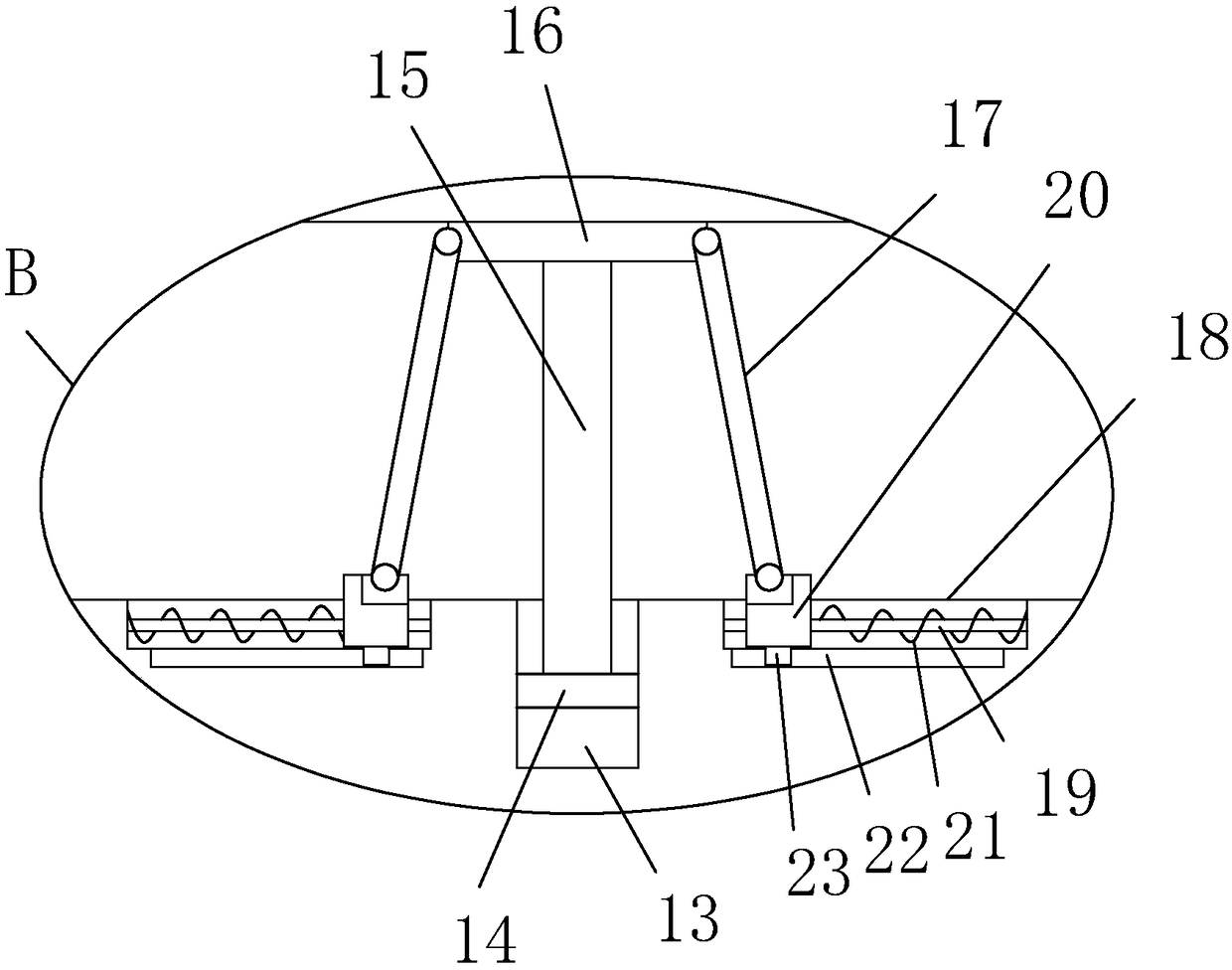

[0046] refer to Figure 1-5 , a pure electric vehicle drive motor is proposed in this embodiment, including a mounting base 1, a mounting groove 2 is provided on the top side of the mounting base 1, a motor body 3 is installed in the mounting groove 2, and a motor body 3 is provided on one side The output shaft 4, the first trapezoidal block 5 is fixedly installed on the inner wall of both sides of the installation groove 2, the both sides of the motor body 3 are provided with a groove 6, and a slider 7 is slidably installed in the groove 6, and the two sliders 7 are fixedly installed with a second trapezoidal block 8 on one side away from each other, the first trapezoidal block 5 is compatible with the second trapezoidal block 8, and the side of the second trapezoidal block 8 away from the slider 7 extends to the outside of the groove 6 and In contact with the first trapezoidal block 5, a first limiting groove 9 is provided on the inner wall of the top side and the inner wall...

Embodiment 2

[0051] refer to Figure 6-13 , this embodiment also includes the following features on the basis of Embodiment 1: the motor body is connected with a cooling assembly; the cooling assembly includes a radiator 90, and is used to transport cooling fluid to circulate between the motor body and the radiator Fluid pump 80 for flow.

[0052] The liquid pump includes a pump casing, a cover body sealingly connected to the open end of the pump casing, a water wheel installed in the pump casing to rotate, and a servo motor connected to the outside of the pump casing to drive the water wheel to rotate through magnetic transmission.

[0053] An overall U-shaped fixing belt 84 for fixing the servo motor is connected to the base by screws.

[0054] The outer wall of the pump housing is integrally formed with a seat body 810, the servo motor is fixedly mounted on the seat body; a drive turntable 86 is fixedly connected to the output shaft of the servo motor, and a drive turntable is fixedly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com