Heat-insulating bed board

A plank and panel technology, applied in the field of furniture, can solve the problems of no heat preservation, single weight bearing, fast heat dissipation, etc., and achieve the effect of preventing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

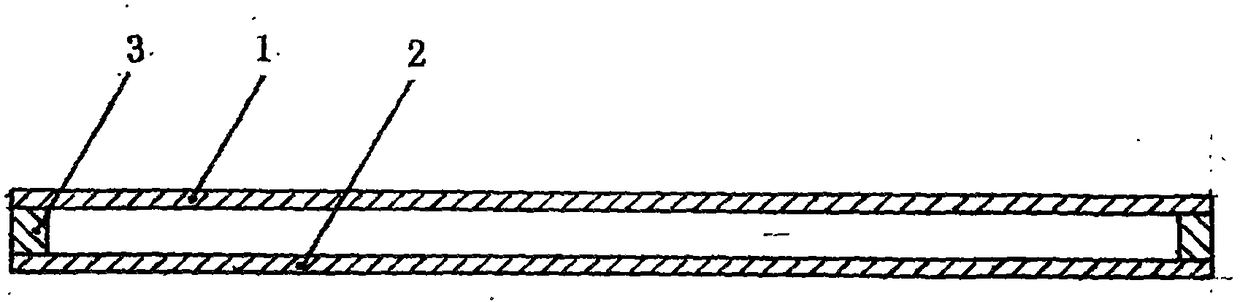

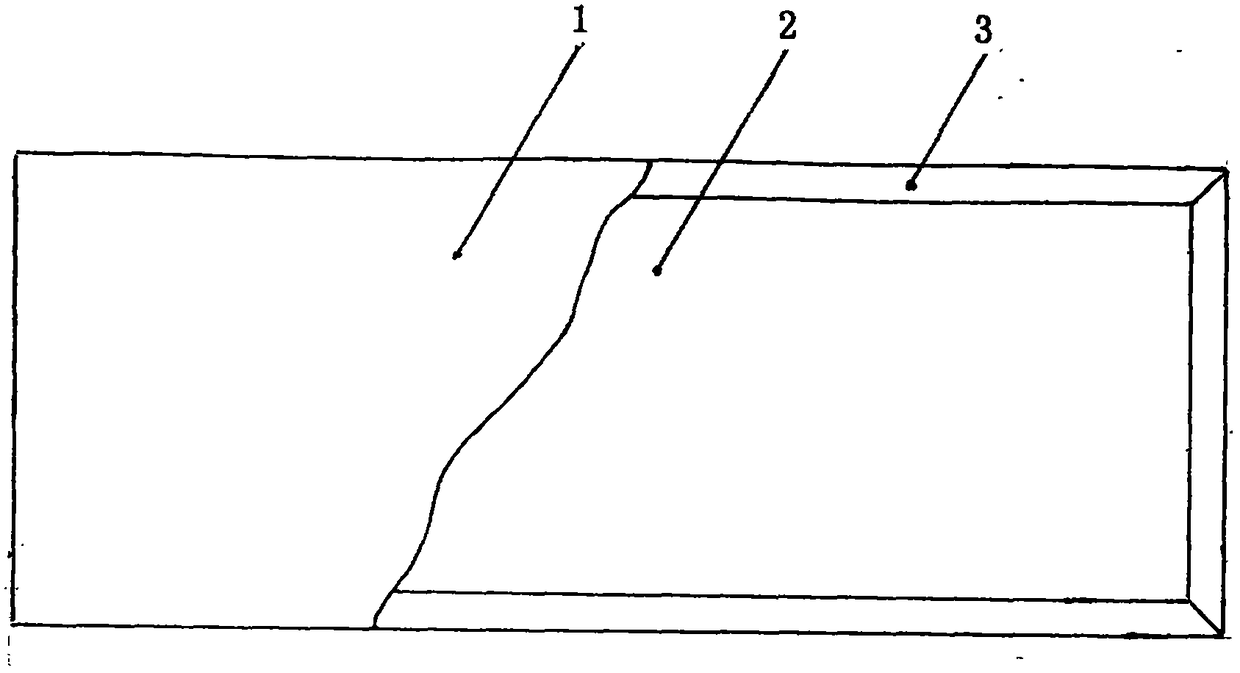

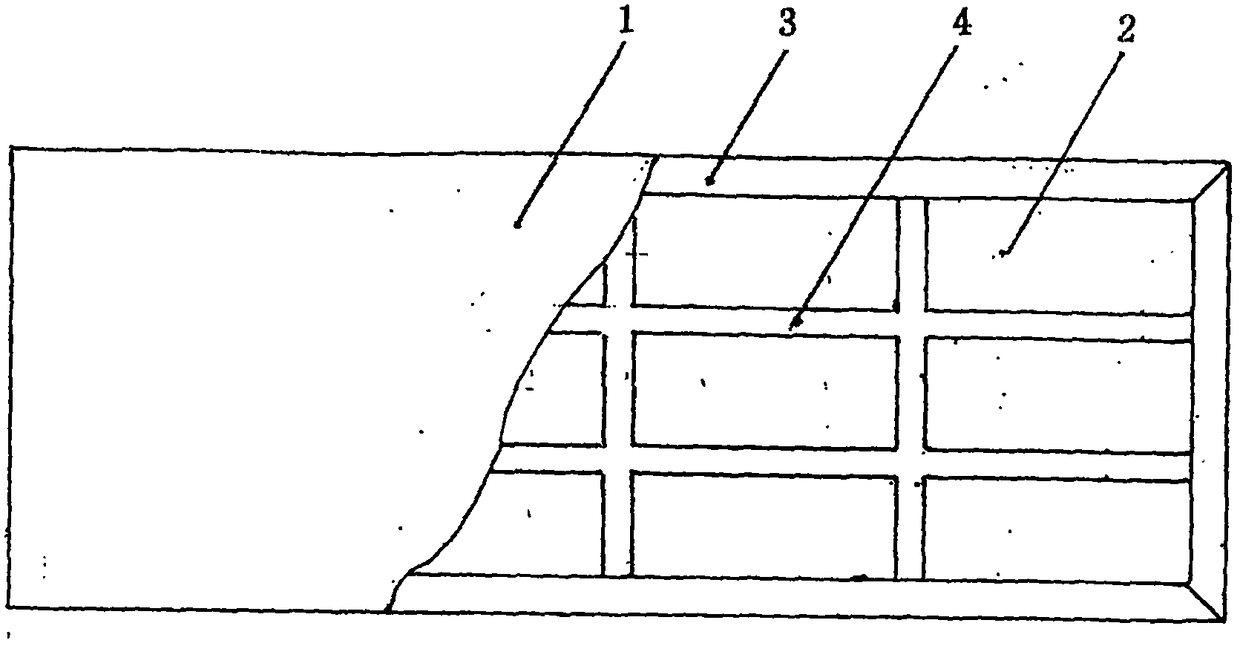

[0013] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the insulation plank is mainly composed of a panel 1, a bottom plate 2, an outer frame 3, a support 4, and a filler 5.

[0014] figure 1 and figure 2 As shown, the outer frame 3 is a quadrangle, the panel 1 is fixed on the top of the outer frame 3, the bottom plate 2 is fixed on the bottom of the outer frame 3, there is a gap between the panel 1 and the bottom plate 2, forming an externally closed and internally hollow assembly;

[0015] image 3 In the first embodiment shown, a support 4 is installed in the gap between the panel 1 and the bottom plate 2, so as to improve the load-bearing capacity of the insulation decking.

[0016] Figure 4 In the second embodiment shown, a filler 5 is installed in the gap between the panel 1 and the bottom plate 2 to impro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com