Liquid cleaning agent composition

A liquid cleaning agent and composition technology, applied in the directions of detergent compositions, surface active detergent compositions, cleaning composition solvents, etc., can solve the problems of not being able to take into account stains at the same time, not giving any technical inspiration, etc. Rich foam, high smearing and cleaning power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

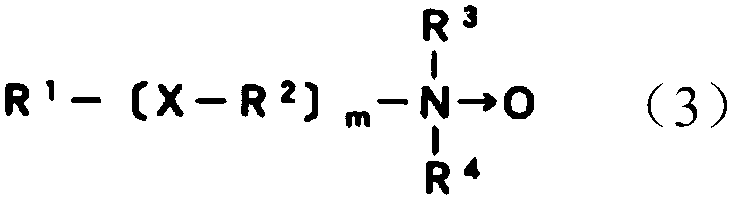

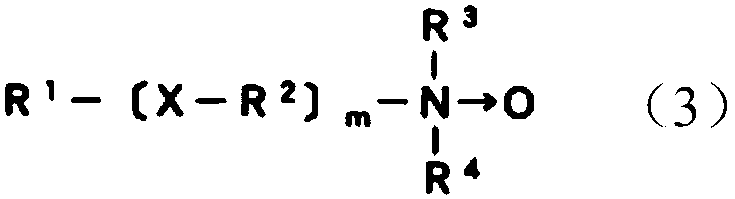

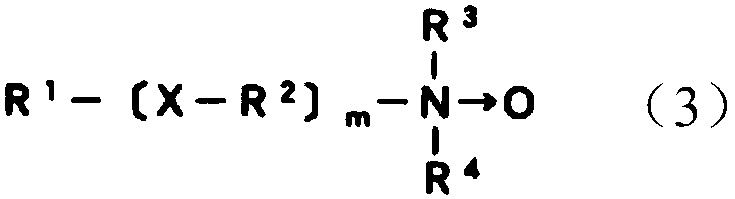

Method used

Image

Examples

Embodiment

[0130] Hereinafter, the embodiments of the present invention are further described and disclosed through examples. The embodiments are merely illustrative of the present invention, and are not intended to limit the present invention in any way. Each component shown in the following table was used, and each liquid detergent composition of an Example and a comparative example was obtained. The numerical value of the amount of each component in the table is expressed in mass% as an effective ingredient, and the balance is deionized water. The value of the mass ratio of the components in the table is described by omitting the denominator ( / 1).

[0131] The components shown in Tables 1 to 9 were mixed to obtain compositions of Examples and Comparative Examples. The following evaluations were performed using each composition obtained. The results are shown in Tables 1-9.

[0132]

[0133] The "Cotton Half Sleeve Shirt for Evaluation" was prepared according to the following method. S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com