An air electric heater with percolation holes on the heating tube

A technology of electric heaters and heating tubes, which is applied in air heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of small effective temperature difference and inability to effectively absorb heat from heating tubes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

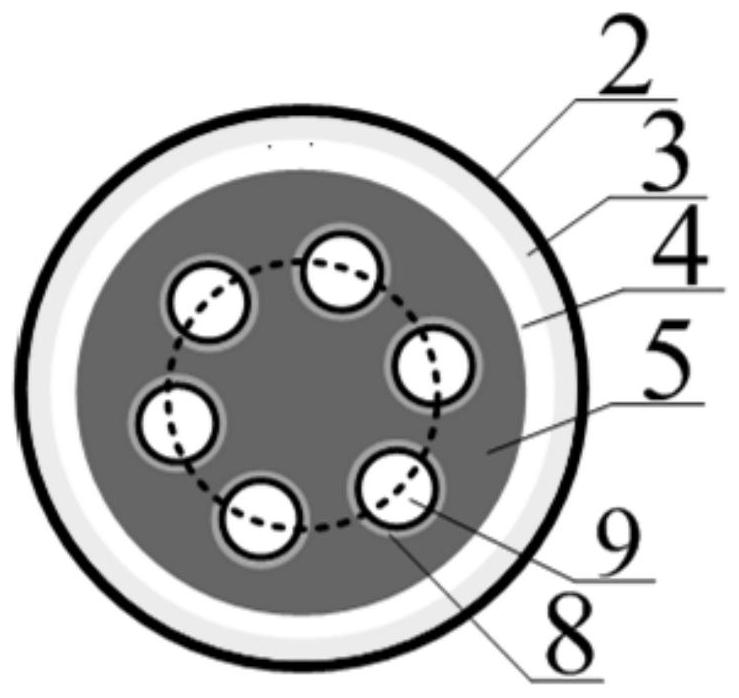

Embodiment 1

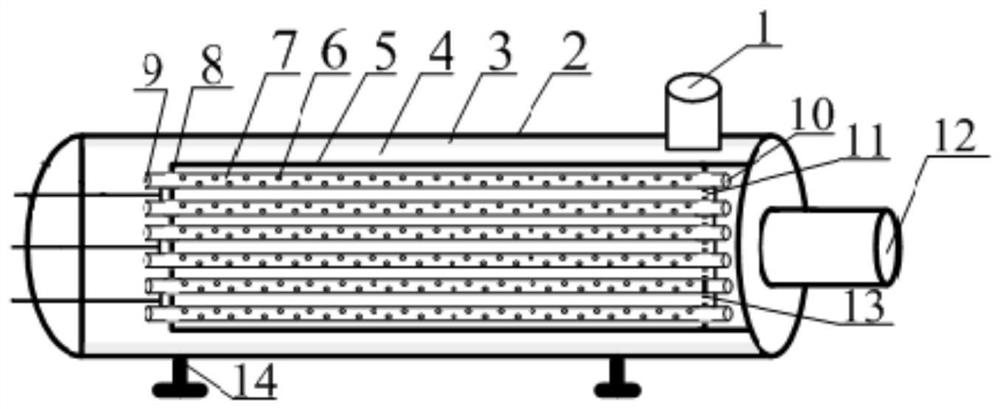

[0025] Embodiment 1: The number of heating tubes is set to 6, and every 2 tubes is a group. The outer diameter of the heating tube 7 is 20 mm, the length of the heating tube 7 is 1500 mm, and the wall thickness is 1 mm. Four rows of circular seepage holes 6 are evenly opened along the axial direction on the heating tube 7, and the adjacent two rows of holes are arranged in a staggered arrangement. The diameter of the seepage holes 6 is 3 mm, and the distance between the centers of adjacent seepage holes 6 in each row is 12 mm. . The heater shell 2 has a diameter of 200mm, and the heater cylinder 5 has a diameter of 160mm. The heater air inlet 1 has a diameter of 100mm, and the heater air outlet 12 has a diameter of 100mm.

[0026] Cold air 16 flows in from the air inlet 1 of the heater, passes through the air flow area 4 between the insulation layer 3 and the heating core cylinder 5, and enters the heating tube 7 at the heating tube inlet 9, and a part flows from the heating ...

Embodiment 2

[0028] Embodiment 2: There are 3 heating tubes, each one is a group, the outer diameter of the heating tube is 10 mm, the length of the heating tube is 500 mm, and the wall thickness is 1 mm. Four rows of circular seepage holes are evenly opened on the heating tube along the axial direction, and the adjacent two rows of holes are arranged in a staggered arrangement. The diameter of the seepage holes is 3mm, and the distance between the centers of adjacent seepage holes in each row is 12mm. The diameter of the heater shell is 150mm, and the diameter of the heater cylinder is 100mm. The heater air inlet diameter is 50mm and the outlet diameter is 50mm.

[0029] Cold air 16 flows in from the heater air inlet 1, passes through the air flow area 4 between the insulation layer and the heating core cylinder, and enters the heating pipe 7 at the heating pipe inlet 9, and part of it flows from the heating pipe air outlet 10 to the heater air A part of the outlet 12 flows from the seep...

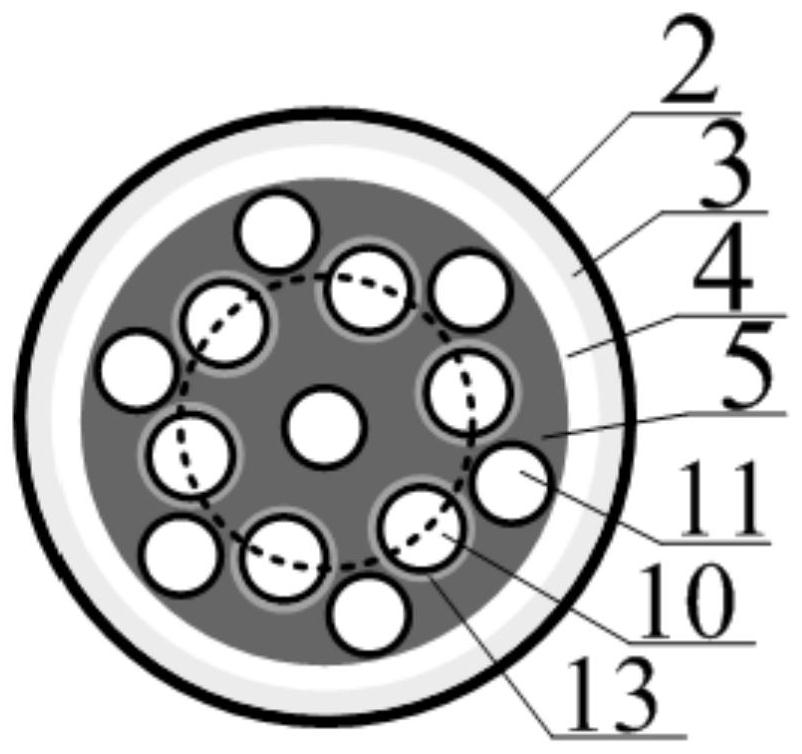

Embodiment 3

[0031] Embodiment 3: 15 heating tubes, 5 tubes each as a group, the outer diameter of the heating tube is 10 mm, the length of the heating tube is 3000 mm, and the wall thickness is 1 mm. Four rows of circular seepage holes are evenly opened on the heating tube along the axial direction, and the adjacent two rows of holes are arranged in a staggered arrangement. The diameter of the seepage holes is 3mm, and the distance between the centers of adjacent seepage holes in each row is 12mm. The diameter of the heater shell is 400mm, and the diameter of the heater cylinder is 300mm. The heater inlet diameter is 100mm, and the outlet diameter is 100mm.

[0032] The cold air 16 flows in from the heater inlet 1, passes through the air flow area 4 between the insulation layer and the heating core cylinder, and enters the heating pipe 15 at the heating pipe inlet 9, and part of it flows from the heating pipe air outlet 10 to the heater air outlet 12, a part flows from the seepage hole 6...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap