Circular dual-frequency excitation eddy current probe and method for detecting thick-wall deep crack defects

A technology of eddy current probes and detection probes, applied in the direction of material magnetic variables, etc., can solve the problems of difficult detection signal resolution, low probe resolution, low detection speed, etc., achieve high detection efficiency, improve detection depth, and increase signal-to-noise ratio Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

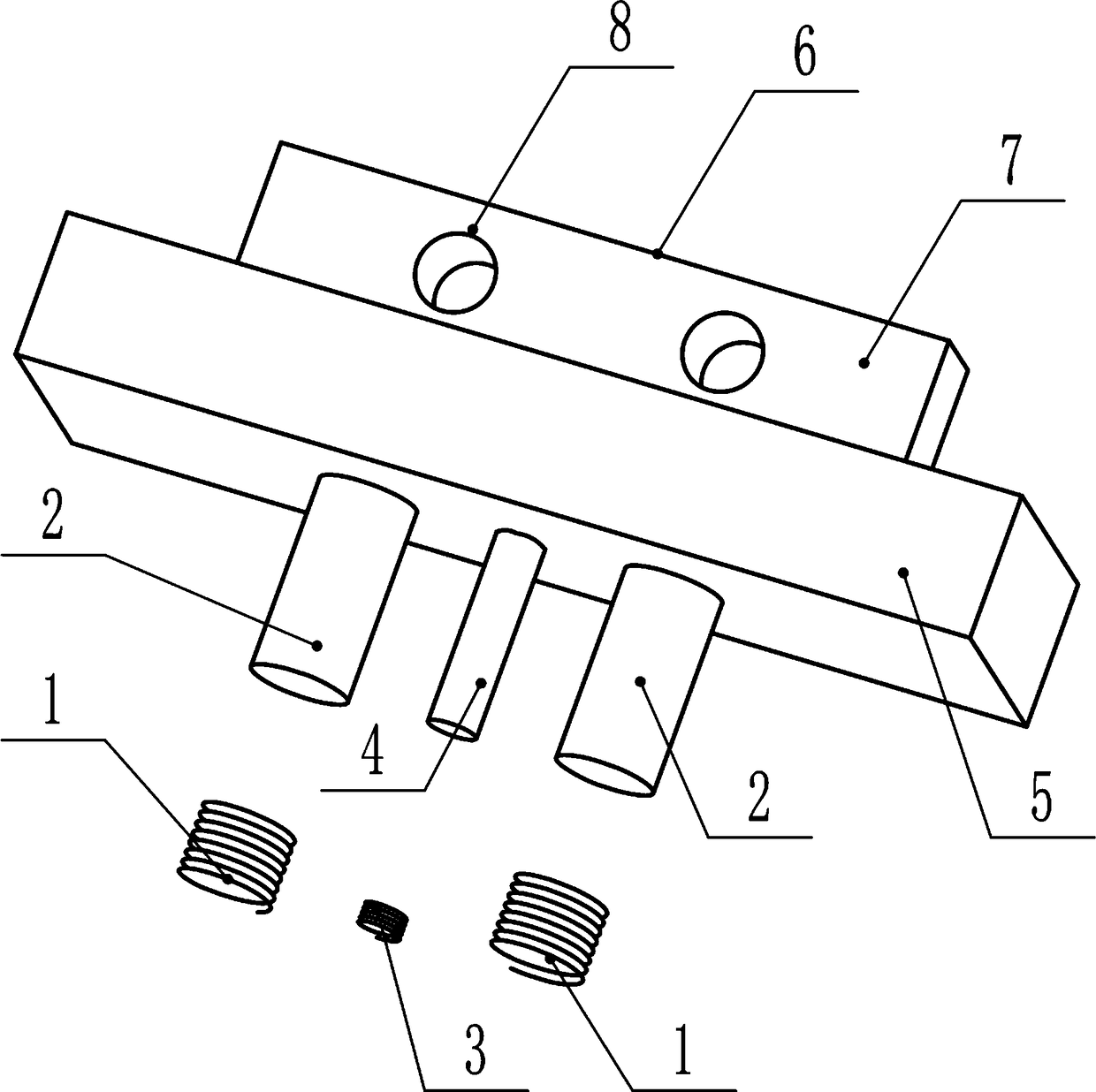

[0043] like figure 1 As shown, a dual-frequency excitation circular eddy current probe for detecting thick-walled deep crack defects is characterized in that: it includes an excitation probe assembly, a detection probe assembly and a fixing frame; the excitation probe assembly has two groups, and the detection probe assembly is The center is distributed symmetrically from left to right; each group of the excitation probe assembly is composed of an excitation coil 1 and a corresponding excitation coil installation column 2, and the excitation coil 1 is set on the excitation coil installation column 2; the detection probe The assembly is composed of a detection coil 3 and a detection coil installation column 4, and the detection coil 3 is set on the detection coil installation column 4; the fixing frame is composed of a column fixing plate 5 and a scanning component connector 6, and the column The fixing plate 5 is fixedly connected with the connecting piece 6 of the scanning co...

Embodiment 2

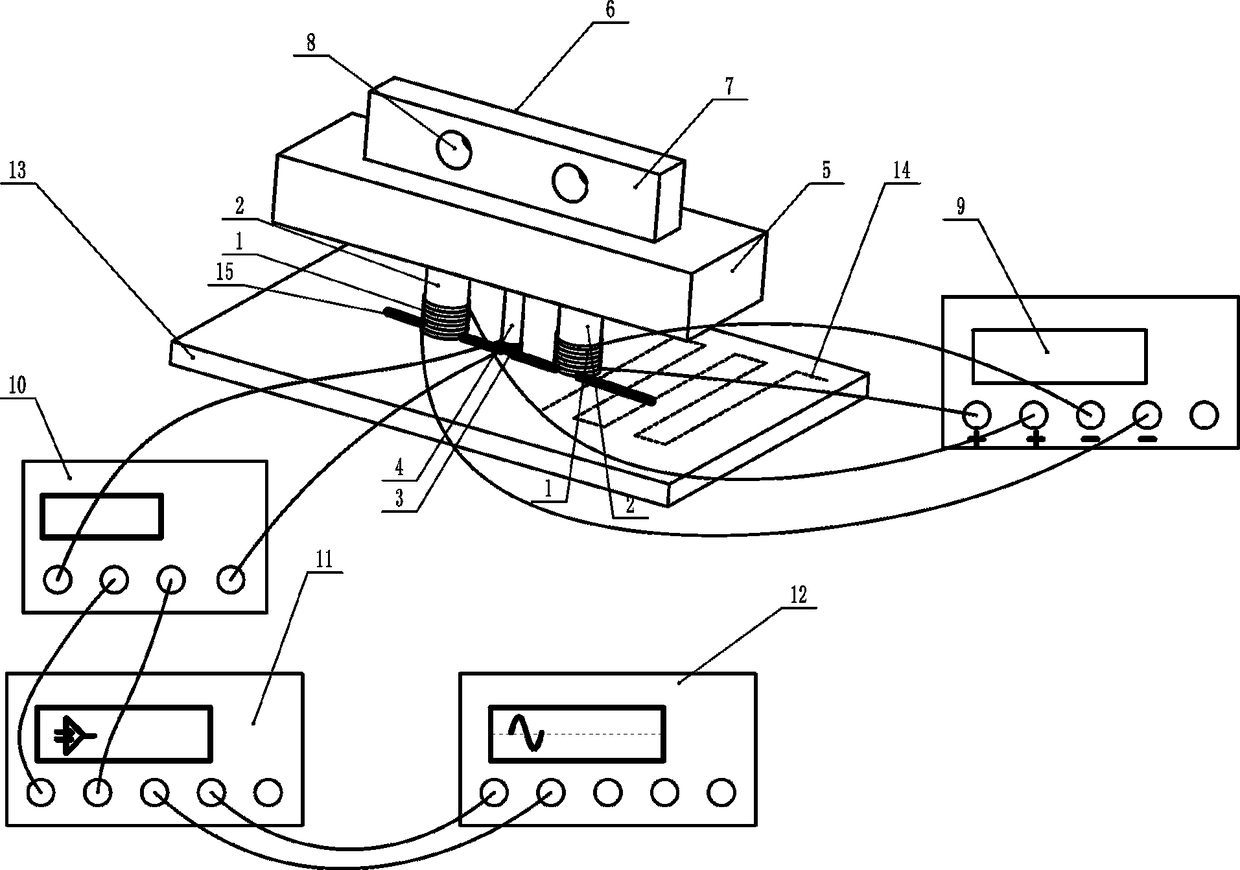

[0059] like figure 2 As shown, on the basis of Embodiment 1, a method for detecting thick-walled deep crack defects with a dual-frequency excitation circular eddy current detection probe is characterized in that it includes the following steps:

[0060] S1. Through the synchronous AC power supply 9, the steady-state sinusoidal excitation currents with different frequencies and sizes are continuously fed to the two groups of excitation coils 1, and the sinusoidal excitation currents generate eddy current fields in the flat metal test piece 13;

[0061] S2. Through the scanning console, the detection probe assembly is C-scanned on the surface of the test piece 13, the eddy current field at the defect is disturbed by the defect, and the defect information is fed back to the detection coil 3 through the disturbance magnetic field;

[0062] S3. Input the detection signal in the detection coil 3 into the filter 10, and utilize the filter 10 to filter out the high-frequency noise wh...

Embodiment 3

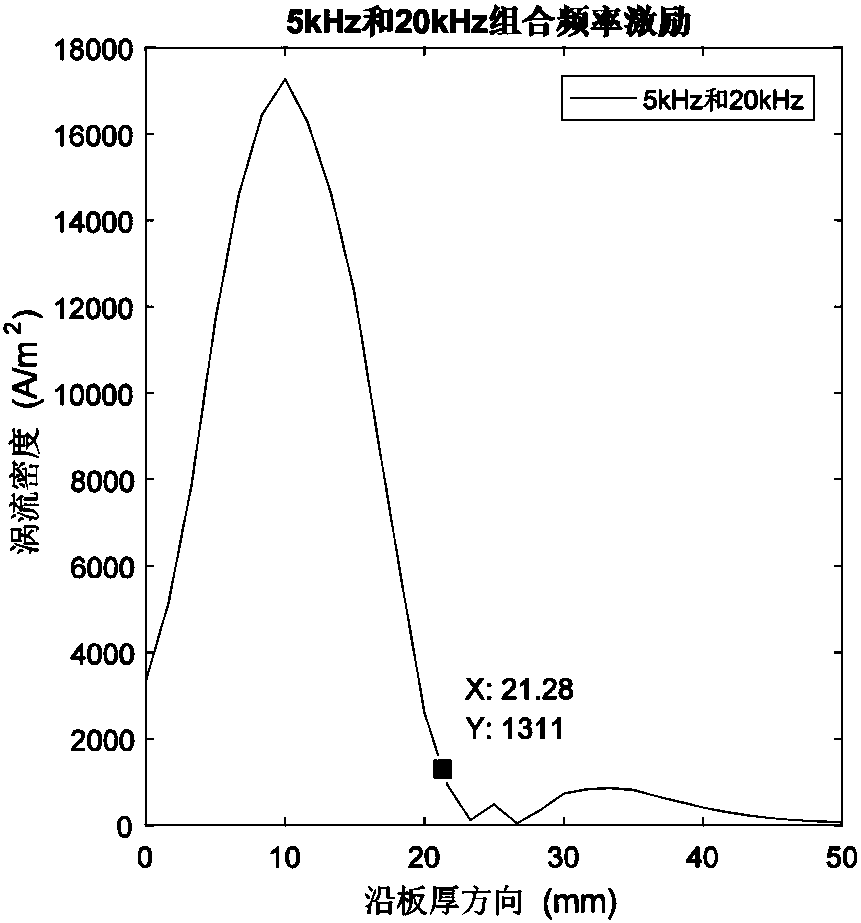

[0066] In order to verify that the penetration depth of the dual-frequency excitation circular eddy current detection probe is better than that of the corresponding single-frequency excitation probe when detecting thick-walled deep crack defects, on the basis of Example 2, two excitation frequencies of 5kHz and 20kHz were used to conduct single-frequency Contrastive experiments of the penetration depth of the excited eddy current probe and the dual frequency excited eddy current probe.

[0067] 1. When using a dual-frequency excitation circular eddy current detection probe for experiments, input a current of 5 kHz and 1.3 A into the excitation coil 1 located on the left side of the detection coil 3, and input a current of 20 kHz and 1.3 A into the excitation coil 1 located on the right side of the detection coil 3. 0.7A current; the configuration parameters, detection methods and results of the dual-frequency excitation eddy current probe are as follows:

[0068] 1) Configurat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration depth | aaaaa | aaaaa |

| penetration depth | aaaaa | aaaaa |

| penetration depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com