Separate base assembly applicable to monolithic epitaxial furnace

A separate, epitaxial furnace technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of uneven temperature distribution, deterioration of nanometer topography, uneven temperature of substrates, etc. Morphology, the effect of reducing backside deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

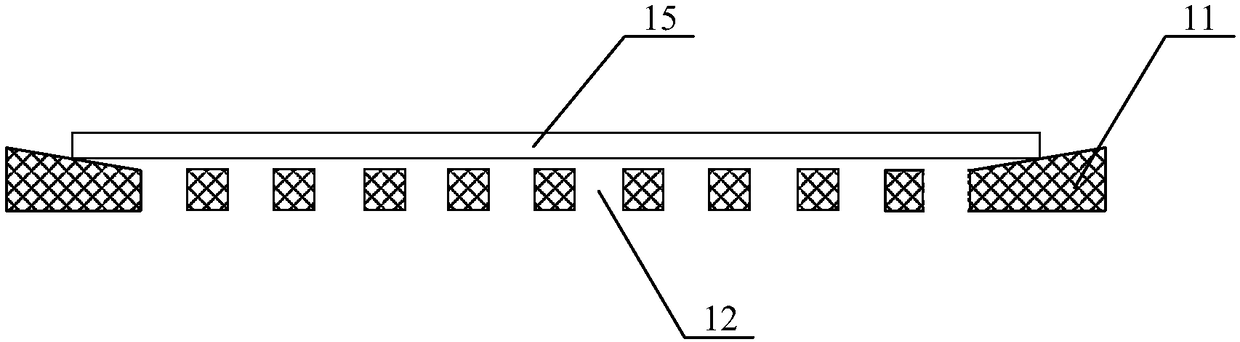

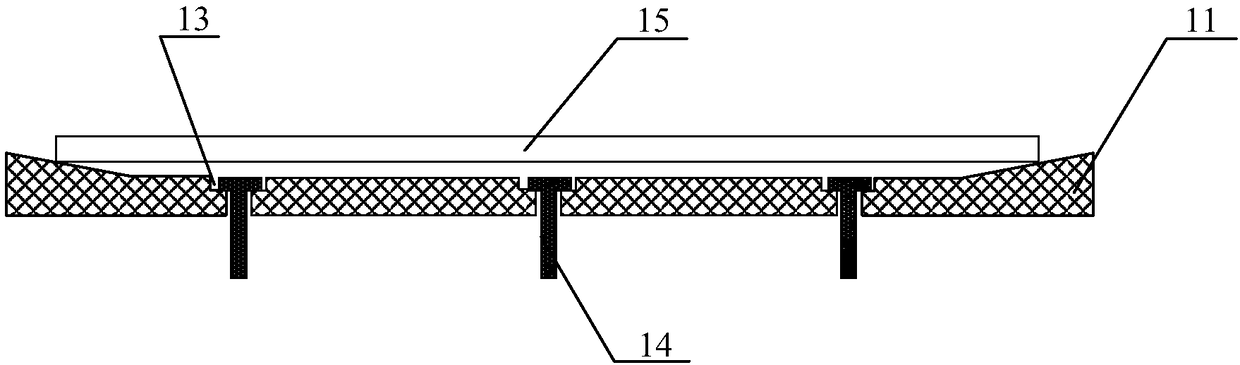

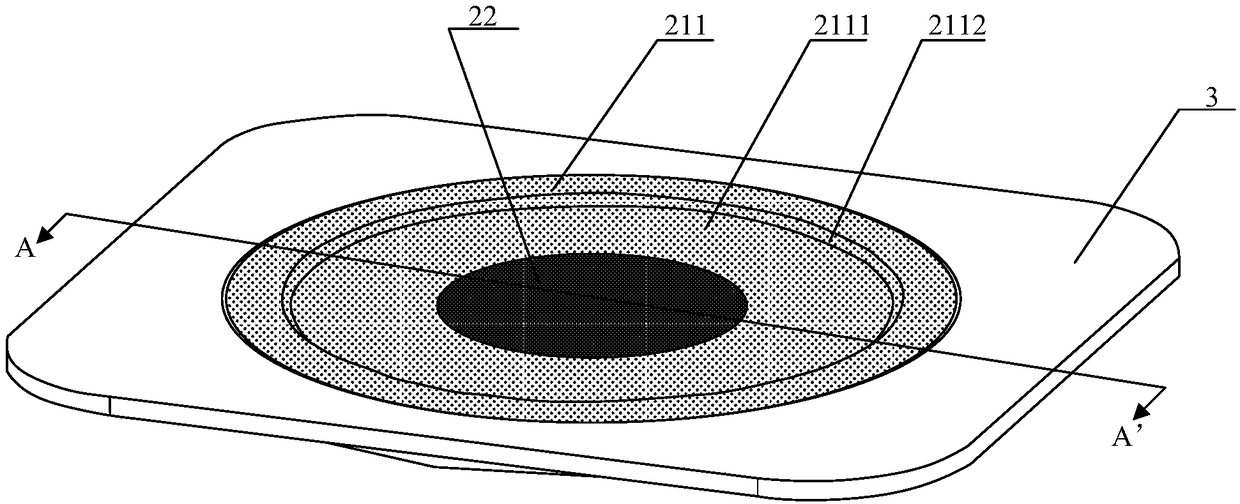

[0059] See Figure 3 to Figure 7 The present invention provides a separate base assembly suitable for a monolithic epitaxial furnace. The separate base assembly includes a separate base 2, and the separate base 2 includes a first part 21, and the second The part 21 includes a main body part 211 and a hollow part 212, the hollow part 212 penetrates the main body part 211 along the thickness direction of the main body part 211; the second part 22, the second part 22 includes a flat part 221, The shape and size of the flat portion 221 are the same as those of the hollow portion 212, the second portion 22 is used in cooperation with the first portion 21, and the second portion 22 is used in cooperation with the first portion 21 At this time, the flat portion 221 is embedded in the hollow portion 212, and the upper surface of the flat portion 221 is flush with the upper surface of the main body portion 211 adjacent to the outside of the hollow portion 22.

[0060] As an example, the u...

Embodiment 2

[0068] See Figure 9 to Figure 13 This embodiment also provides a separate pedestal assembly suitable for monolithic epitaxial furnaces. The structure of the separated pedestal assembly suitable for monolithic epitaxial furnaces described in this embodiment is the same as that described in the first embodiment. The structure of the separate base assembly suitable for the monolithic epitaxial furnace is roughly the same. The difference between the two is: in the first embodiment, the main body 211 is an annular main body, and the hollowed-out portion 212 is located at the The through hole inside the main body portion 211; the separate base assembly further includes a first pre-heating ring 3 and a first tray 4; the first pre-heating ring 3 is located on the periphery of the separate base 2; The first tray 4 is located inside the first pre-heating ring 3, and the upper surface of the first tray 4 is lower than the upper surface of the first pre-heating ring 3. The first tray 3 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com