Versatile process for precision nanoscale manufacturing

A substrate and covering technology, applied in the general process field of precision nanoscale manufacturing, can solve the problems of constrained versatility, lack of film thickness range and resolution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

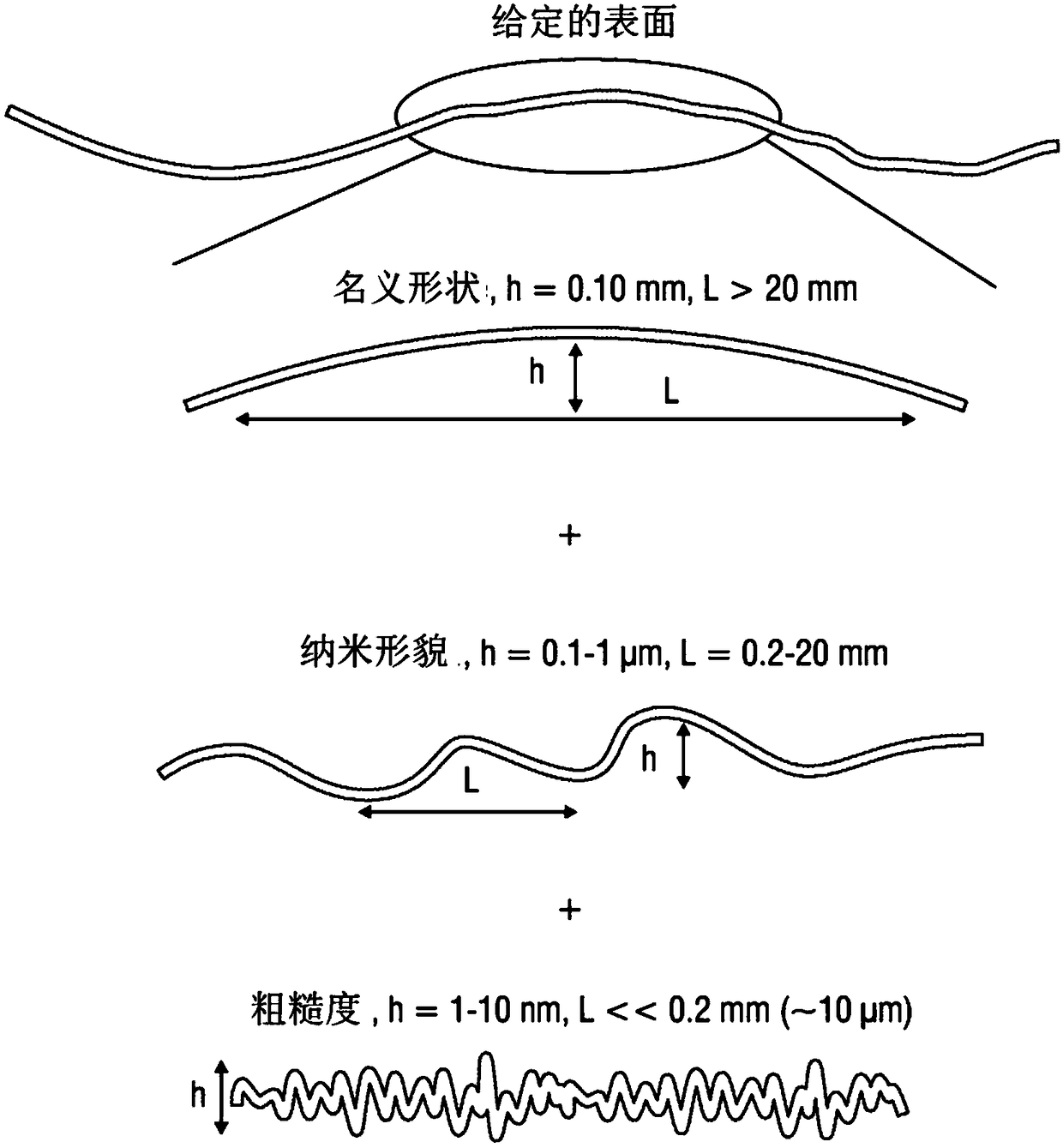

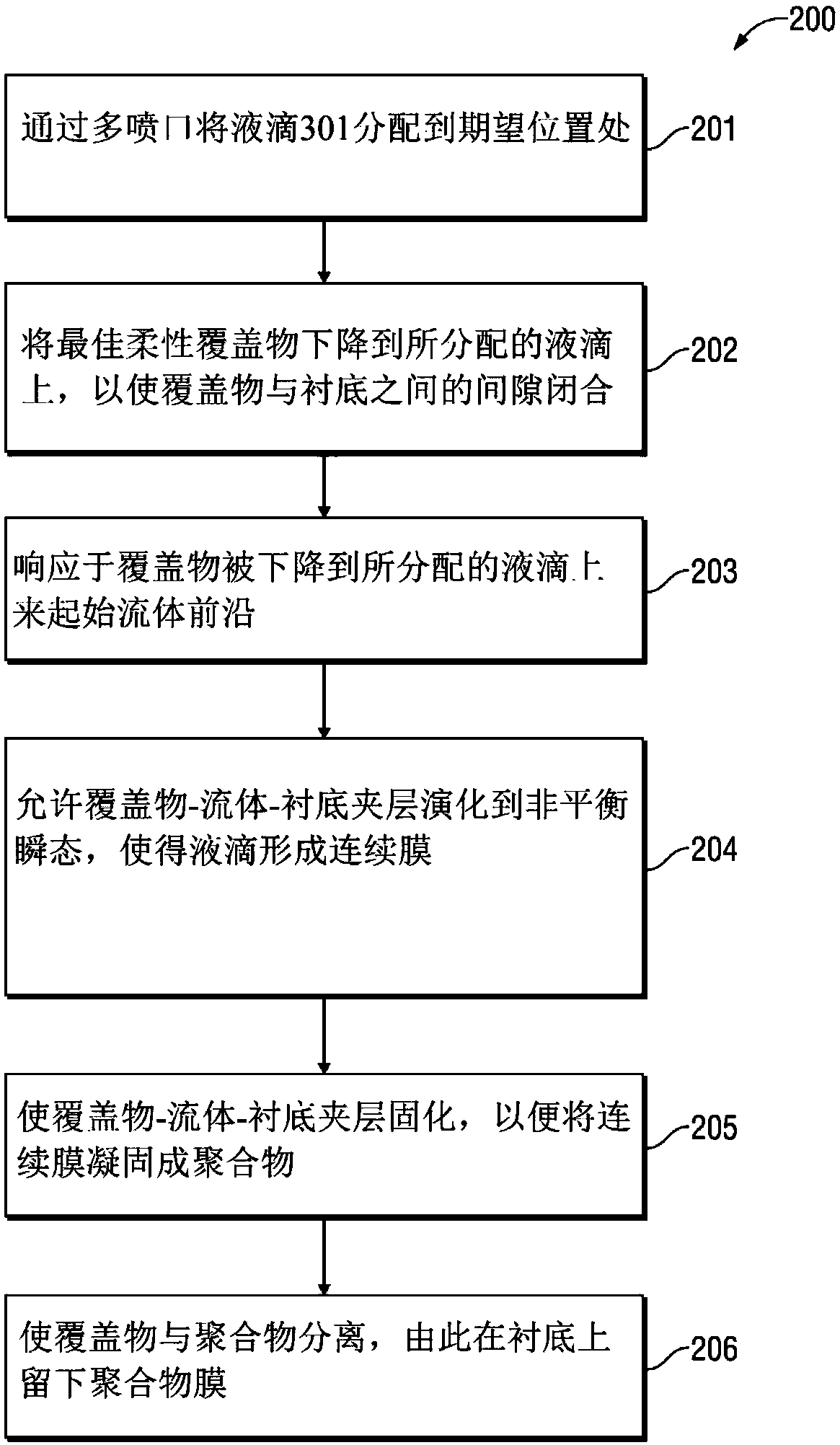

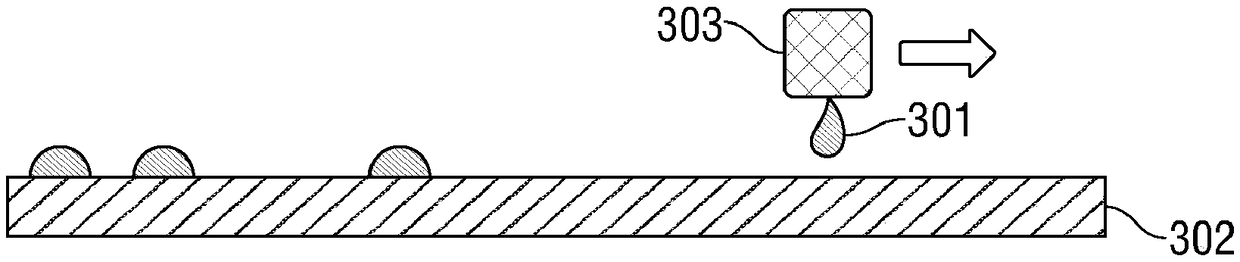

[0028] The present invention presents a general process for three types of precision nanoscale fabrication on both nominally planar substrates and substrates with nominally free-form shapes. As used herein, "nominal shape" refers to a desired shape, and it is assumed that standard manufacturing processes such as machining, diamond turning, and injection molding have achieved this nominal shape close to the ideal desired shape. This means that the nominal shape still has some parasitics beyond acceptable tolerances based on the intended use of the substrate.

[0029] These three types of nanoscale manufacturing (NM) include grinding (referred to herein simply as "NM1"), which involves changing the nominal shape of the substrate. For example, a planar substrate can be changed to a spherical nominal shape, or a spherical nominal shape can be changed to an aspheric surface, etc. The second type of nanoscale fabrication (NM) involves polishing (referred to herein simply as "NM2"),...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com