Flat end stop in a sliding sleeve

A technology for engaging sleeves and stoppers, which is applied to clutches, mechanical drive clutches, mechanical equipment, etc., can solve the problems of difficulty in bending into a circle, affecting accuracy, and difficulty in forming, and achieves the effect of improving calibration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

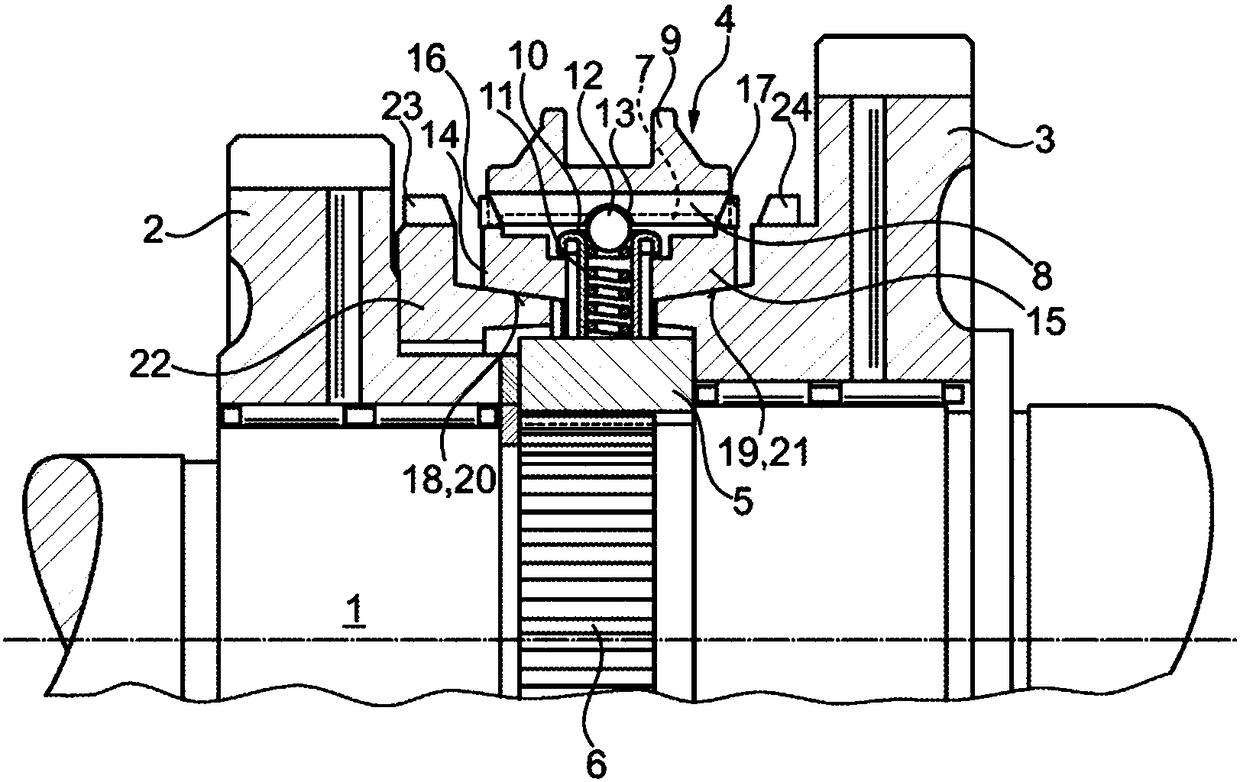

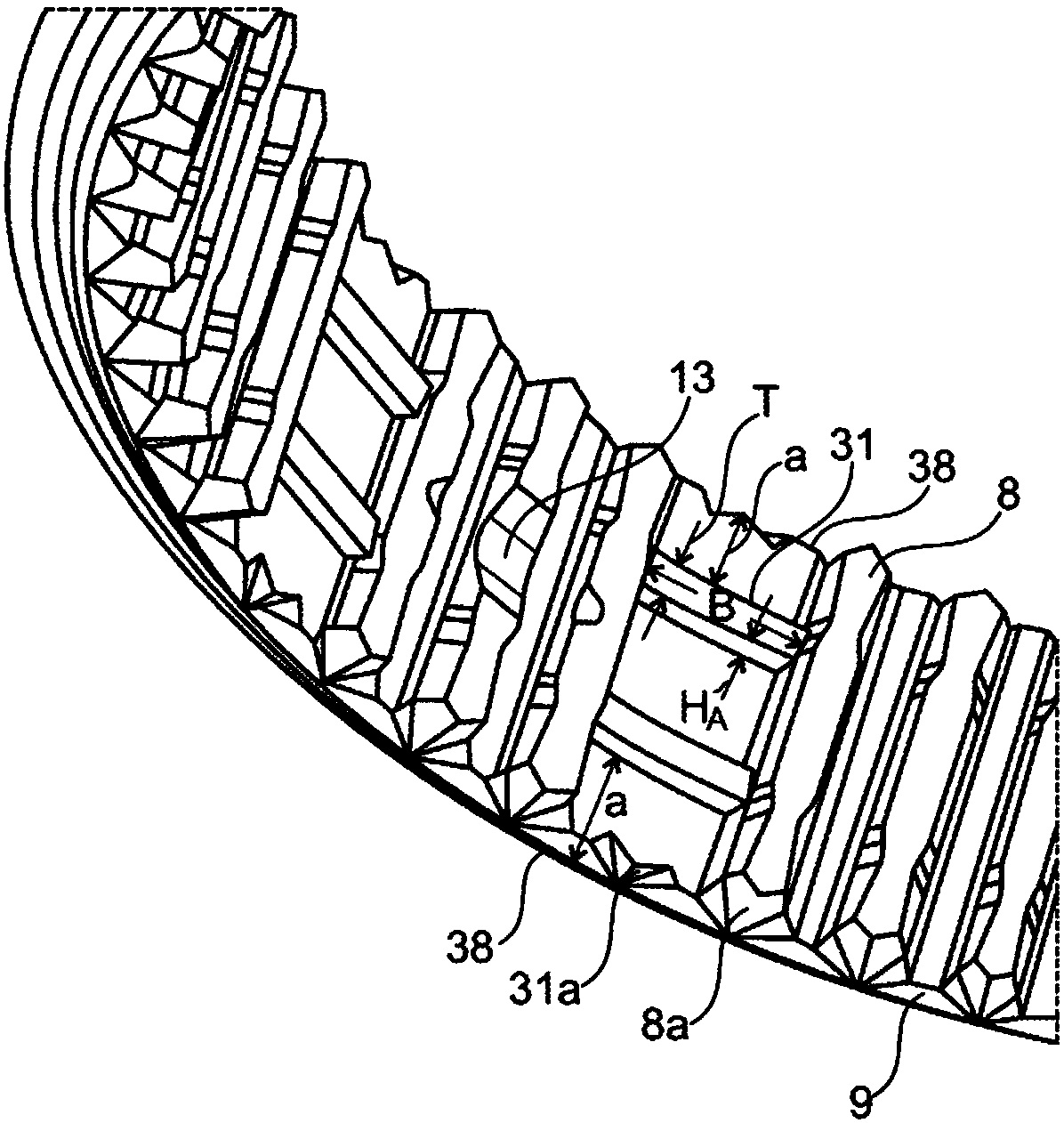

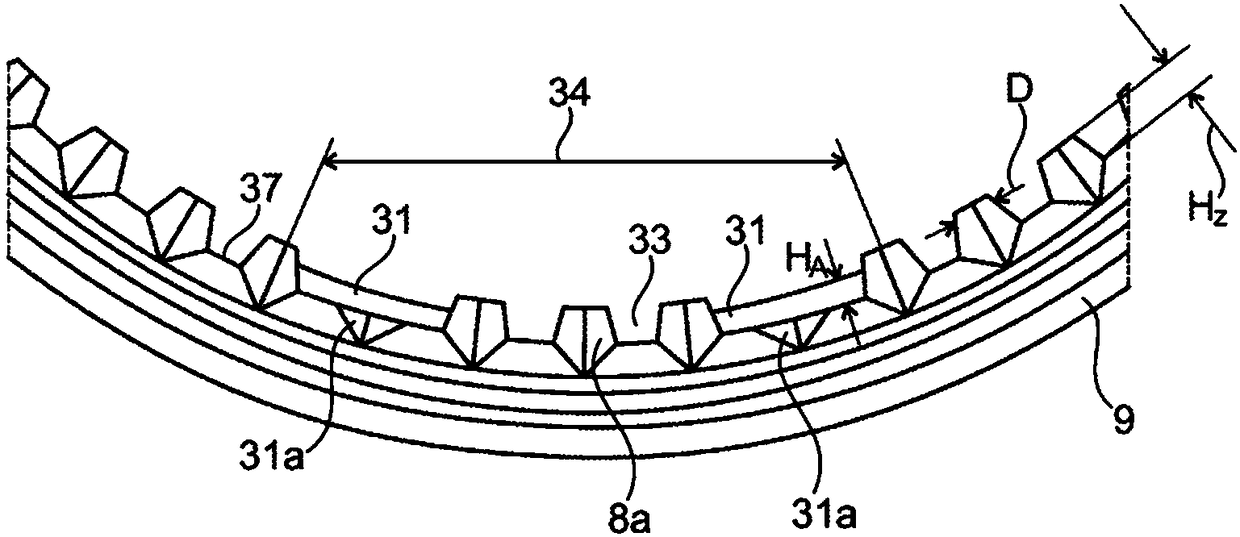

[0019] exist figure 1 Indicated by 1 is a shaft for a gearshift transmission of a motor vehicle on which two gearwheels 2 and 3 are mounted in a freely rotatable manner. Between the two gearwheels 2 and 3 is arranged a synchronization device 4 via which one of the two gearwheels 2 and 3 can be selectively coupled to the shaft 1 . In this way, the shift transmission is switched into different gear stages.

[0020] The synchronization device 4 has a synchronization carrier 5 which engages in a toothing 6 of the shaft 1 in a rotationally fixed manner. Furthermore, the synchronization carrier 5 is provided on its outer circumference with an external toothing 7 into which the teeth 8 of the internal toothing of the clutch sleeve 9 engage. The pressure part 10 is also guided in the synchronization carrier 5 by means of a pressure spring 11 which accommodates a spherical locking element 12 which protrudes from the pressure part 10 in the longitudinal direction. The spherical locki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com