Pressure vessel comprising a load ring, motor vehicle, and method for manufacturing a pressure vessel

A pressure vessel and load ring technology, applied in the field of pressure vessels, can solve problems such as multiple structural spaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

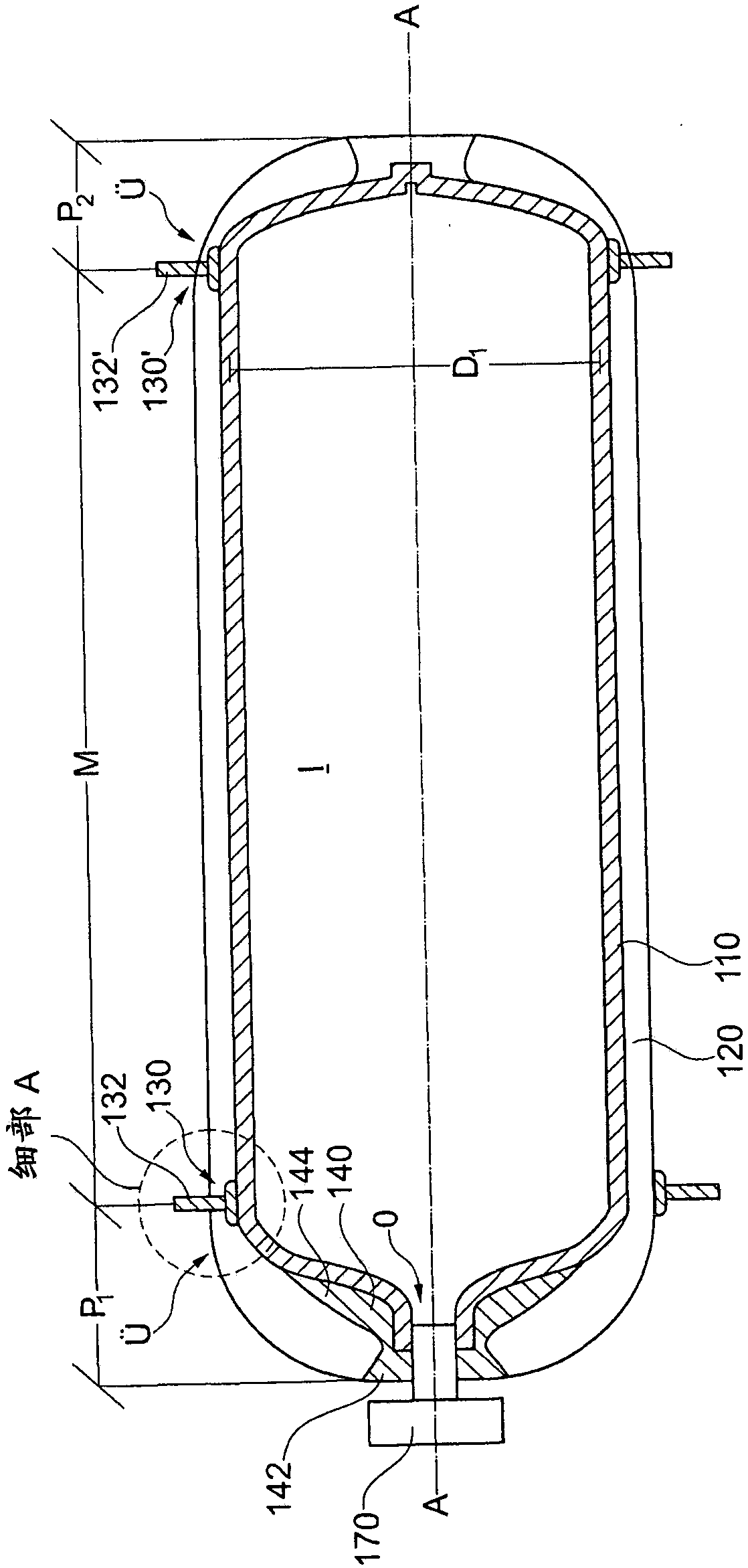

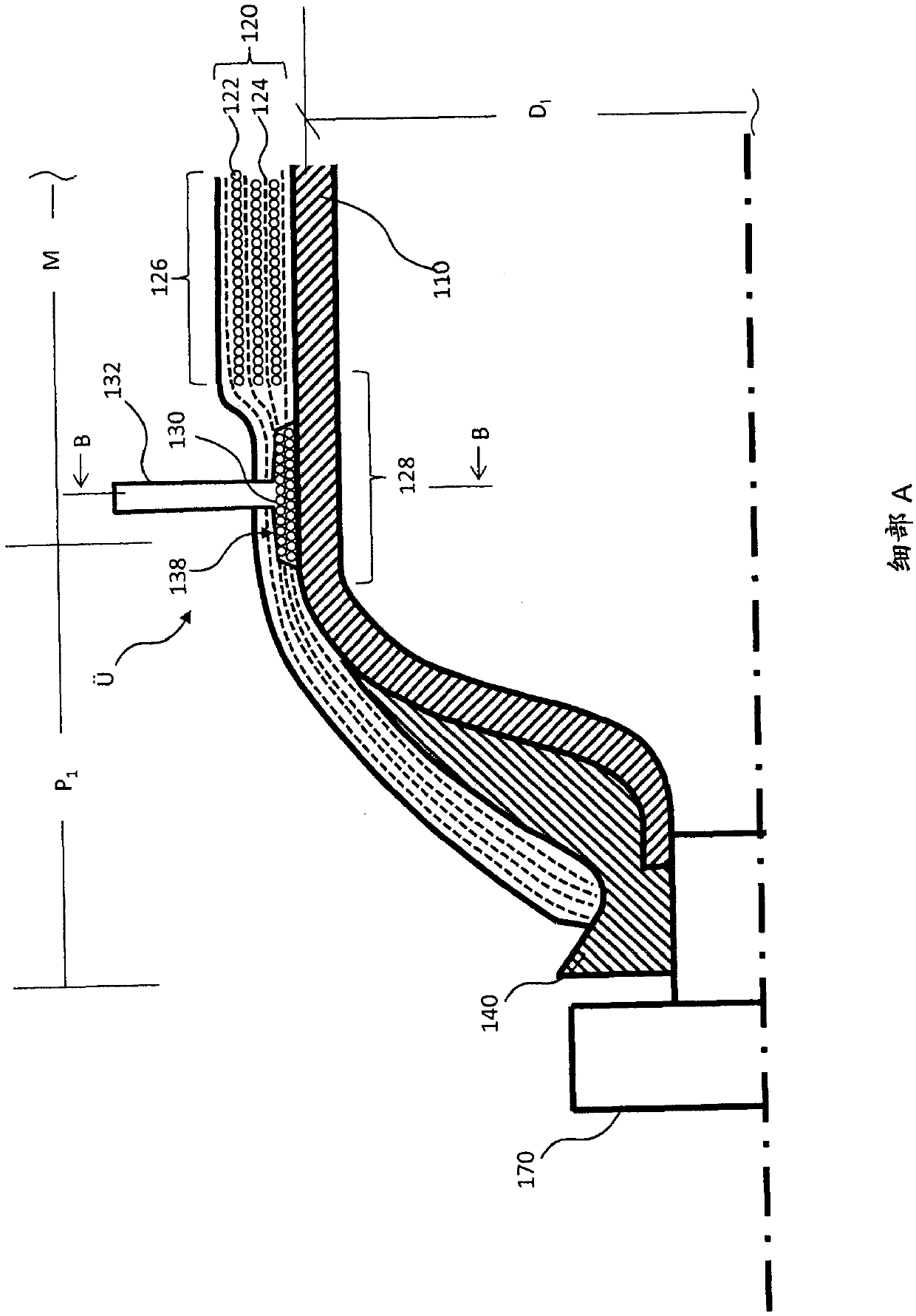

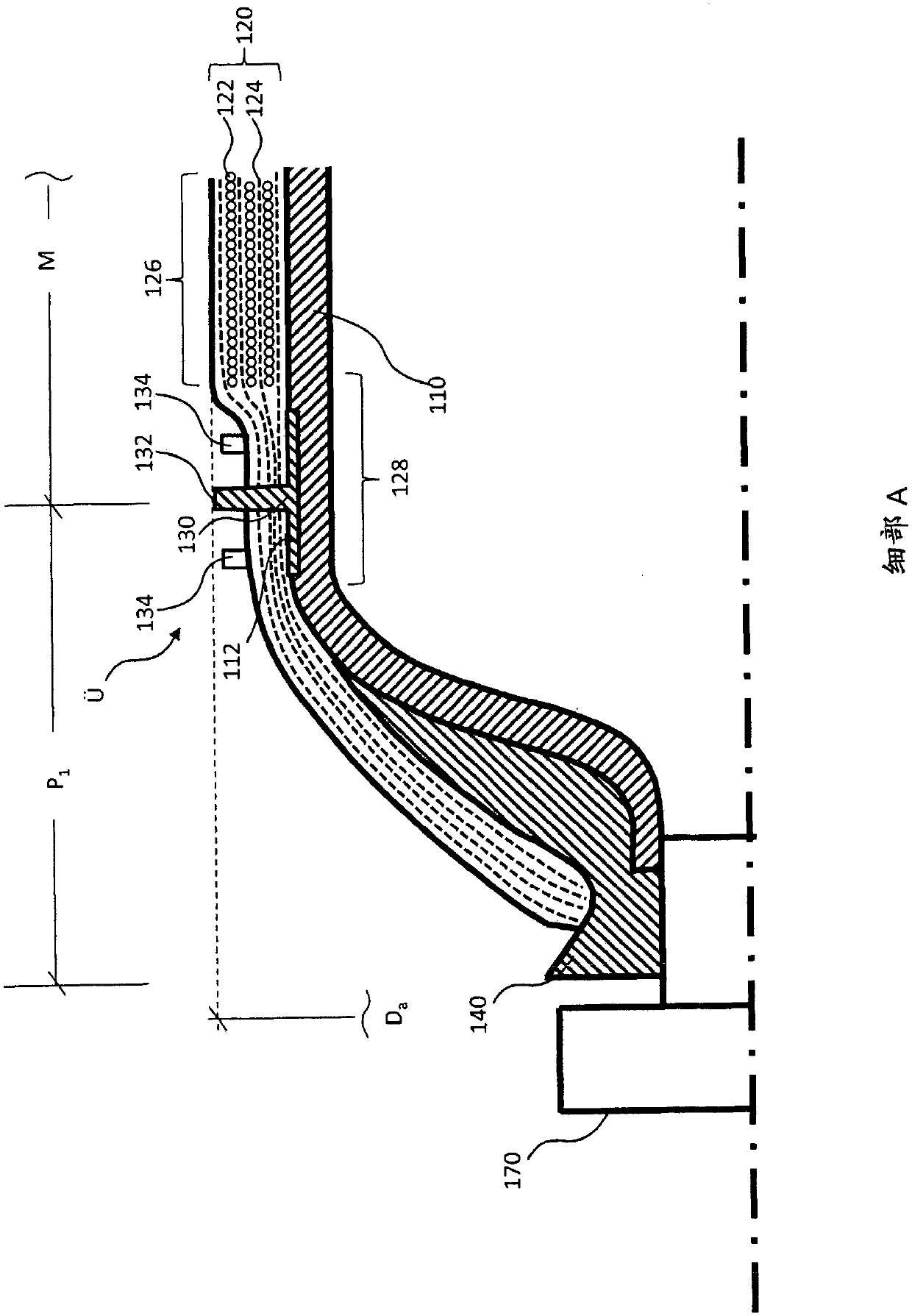

[0040] figure 1 A partial cross-sectional view of a pressure vessel is shown having a liner 110 and a fiber reinforced layer 120 . The inner bladder 110 forms a storage volume 1 for fuel. at the front end P 1 An outlet or hole O for stored fuel is provided on the top. The hole O and the flange 140 cannot be regarded as the connecting pin 132 . Connecting pin 132 is connected from surface 138 of load ring 130 (see Figure 5 ) raised. The connecting pin 132 may have a bearing reinforcement (not shown) at the foot of the connecting pin 132 . The connecting pin 32 is formed in one piece here with the load ring 130 , which bears directly on the inner container 110 here. The load ring 130 protrudes here into the lateral peripheral region M of the pressure vessel or of the inner container 110 . The load ring 130 is here completely covered by the fiber-reinforced layer 120 . Only the connection pins 132 protrude from the fiber-reinforced layer 120 . The protruding portion of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com