An electronic smog core and manufacturing method thereof

A technology of electronic cigarettes and production methods, which is applied in the fields of tobacco, smokers' supplies, applications, etc., can solve the problems of insufficient oil storage in the electronic cigarette core, small evaporation area of e-liquid, and uneven heat distribution, so as to increase the evaporation of e-liquid Large area, smoke oil evaporation area, uniform heat distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention will be described in detail below. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

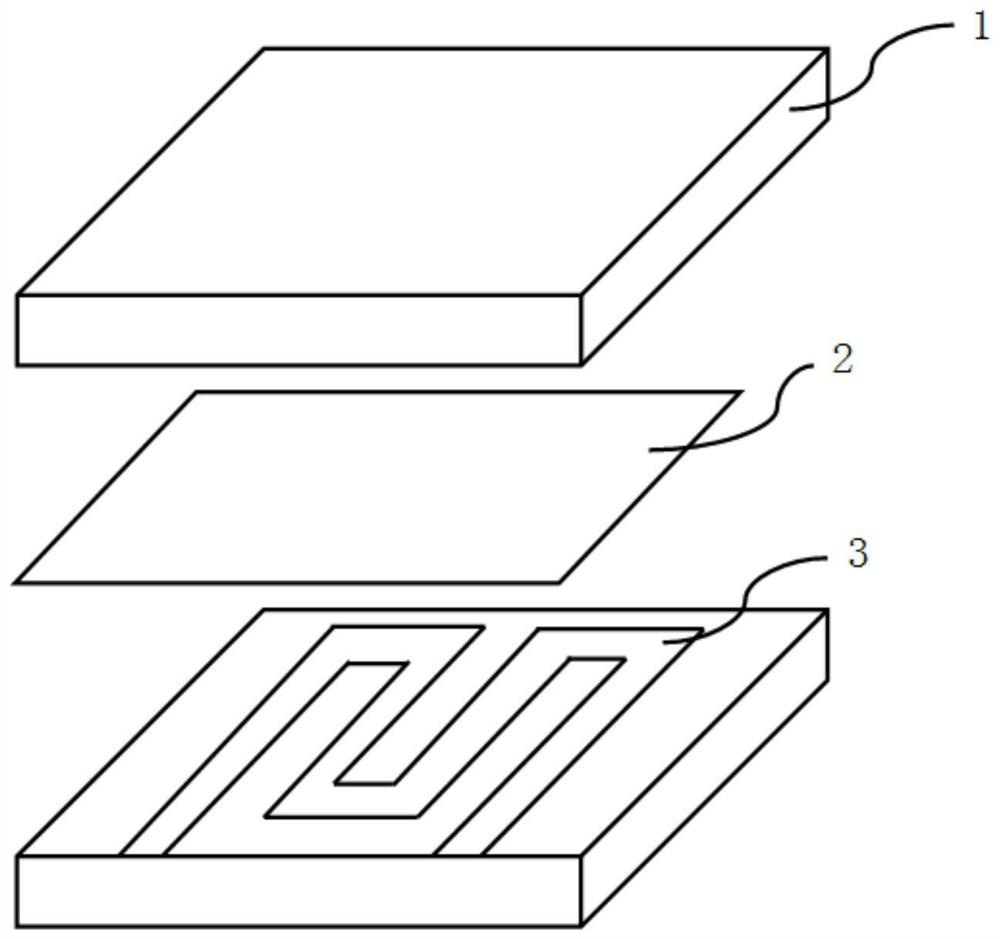

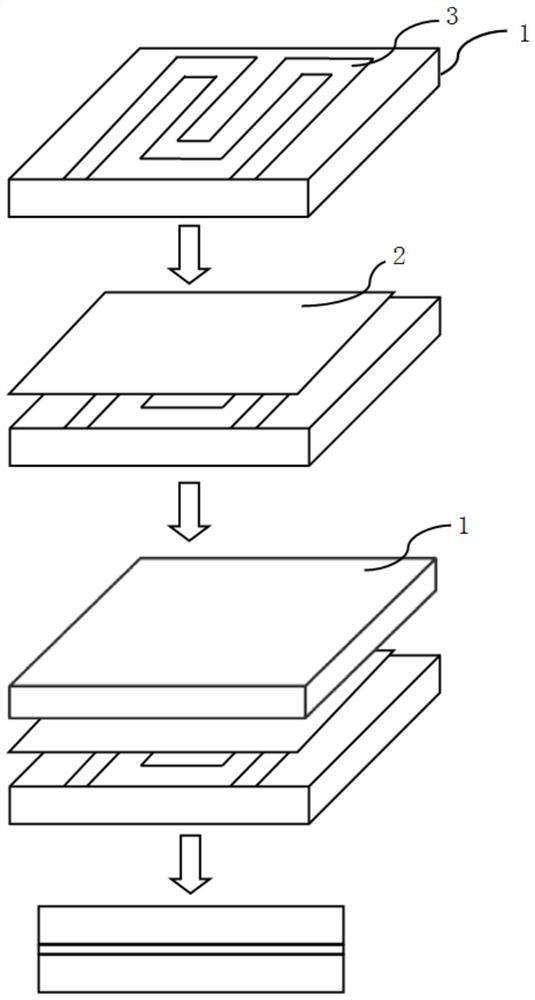

[0027] refer to figure 1 , in one embodiment, an electronic cigarette atomization core, comprising at least two porous ceramic plates 1 stacked, an adhesive medium layer 2 is arranged between adjacent porous ceramic plates 1, wherein at least one porous ceramic plate 1 A heating component 3 is provided on one side of the adhesion medium layer 2 , and the at least two porous ceramic plates 1 are closely bonded and laminated together through the adhesion medium layer 2 , and then sintered to obtain the electronic cigarette atomization core.

[0028] In an embodiment, the size of each porous ceramic plate 1 can be completely the same or different, for example, each porous ceramic plate 1 can have the same area but different thickness.

[0029] In an embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com