Shape memory alloy spectacle leg card set center and process

A memory alloy and spectacle leg technology, which is applied in metal processing, metal processing equipment, assembly machines, etc., can solve the problems of high labor intensity and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

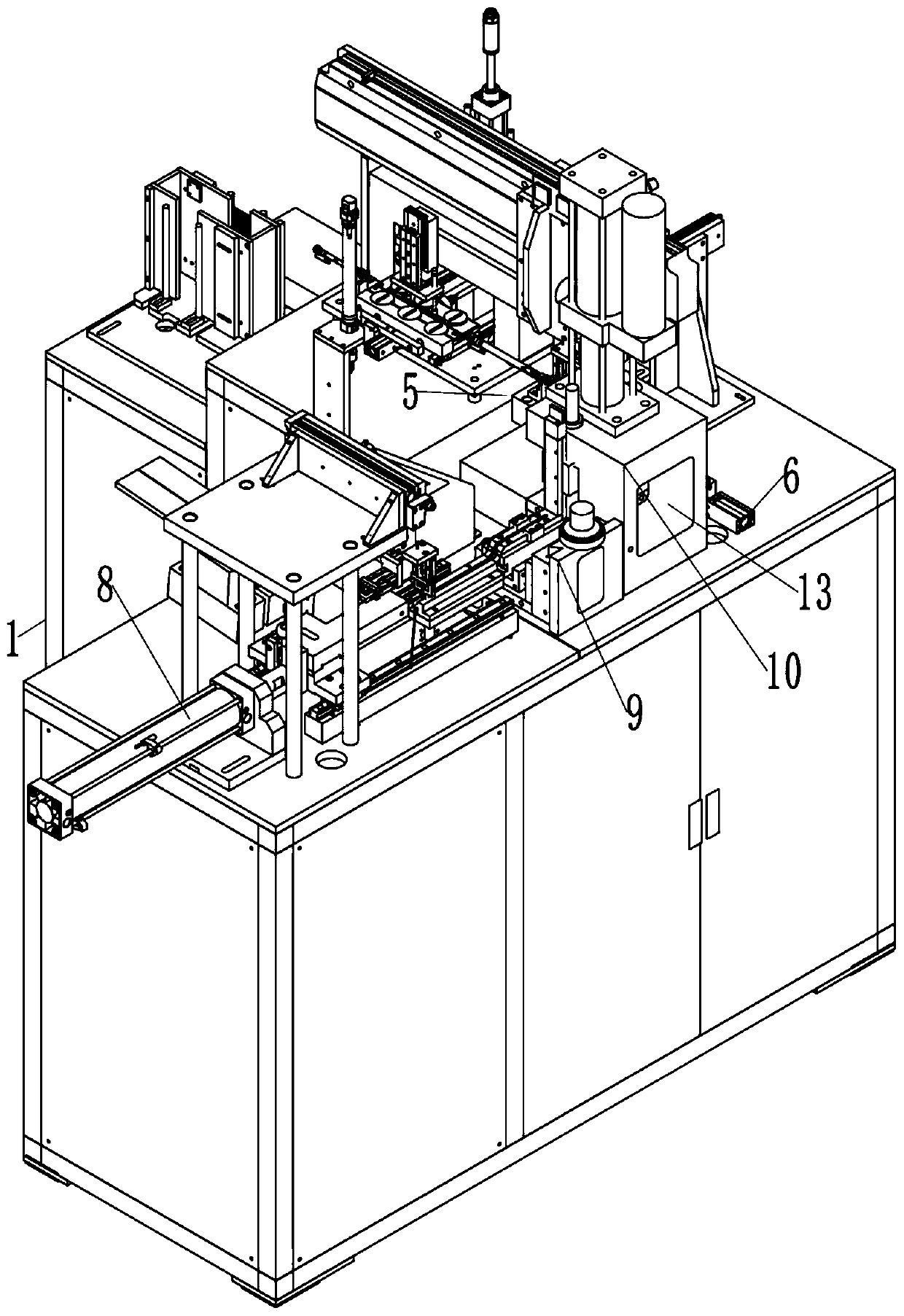

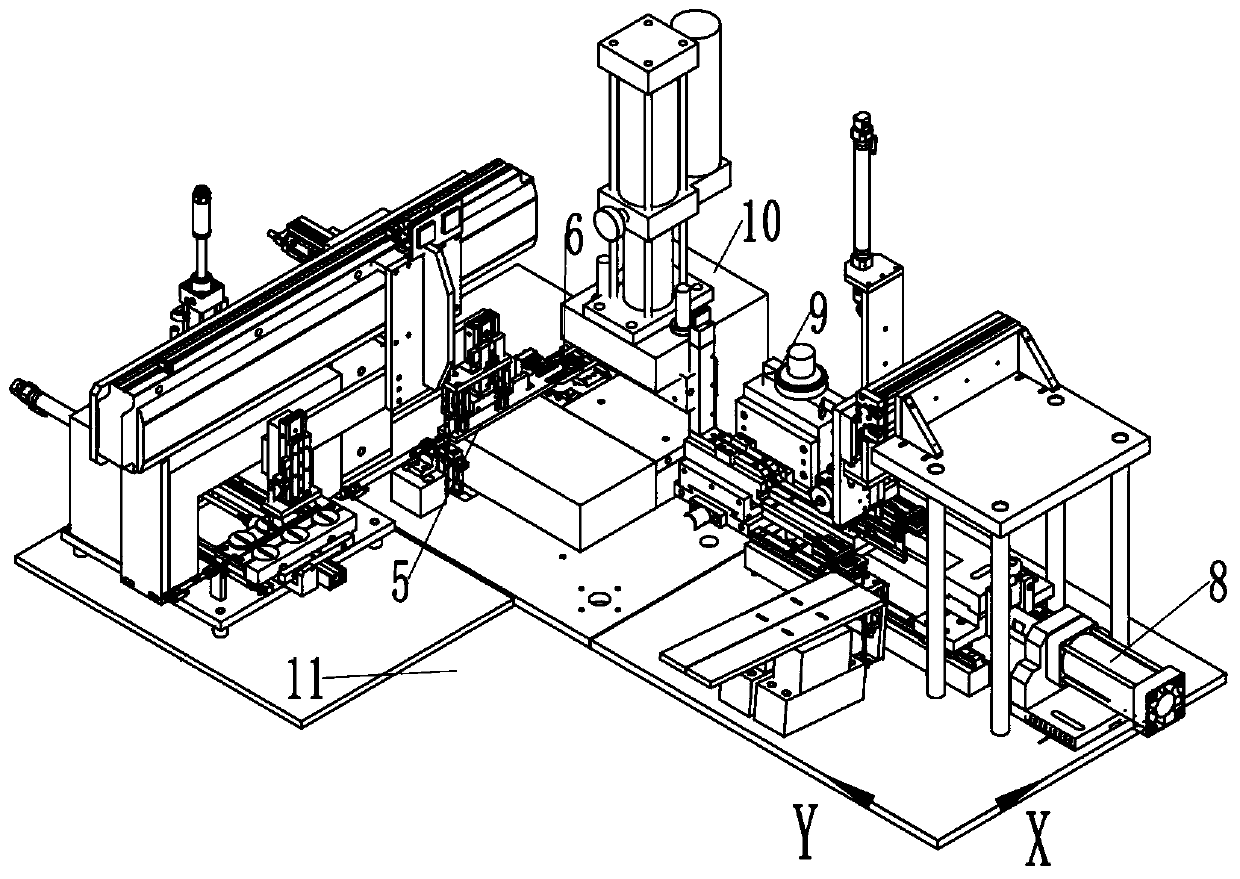

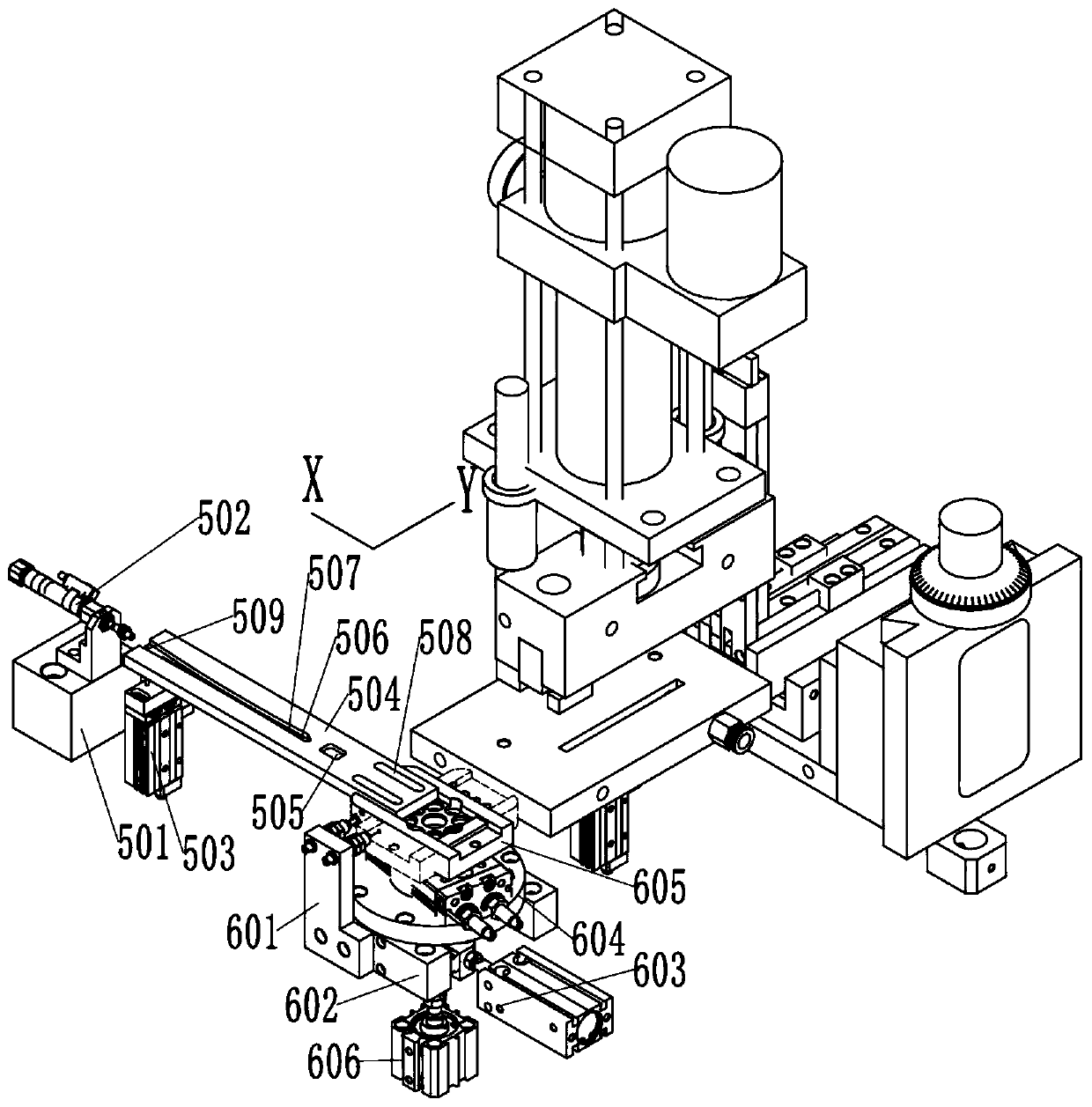

[0029] Such as Figure 1-7 As shown, the shape memory alloy spectacle leg card group center of this embodiment includes the frame 1, and the automatic assembly is realized through the card group center, which has strong versatility and high efficiency, improves the existing rubber-covering production method, reduces pollution, and realizes green Production.

[0030] The card group center includes a card grouping device 5 for grouping glasses legs 11, a rotary station device 6 arranged on one side of the card grouping device 5, and a memory metal frame for storing horizontal states. The push device 8 of wire 12, the guide device 9 that is arranged on one side of the push device 8 and is used to guide the memory metal wire 12 pushed by the push device 8, is arranged between the guide device 9 and the rotary station device 6 for memory The metal wire 12 is inserted into the assembly station device 10 in the temple 11 , and the discharge port 13 is arranged on one side of the ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com