Edge glue removing device for integrated insulation boards

An insulation board and edge technology, which is applied in the field of edge glue removal devices, can solve the problems of unclean removal, lower yield, labor-intensive and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

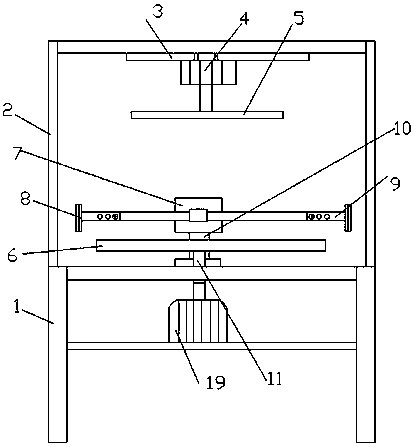

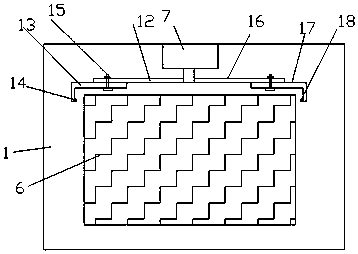

[0023] Such as figure 1 , 2 As shown, the technical solution of the present invention is an edge glue removal device for an integrated thermal insulation board, including an N-shaped frame 1, and a fixing mechanism, a cleaning mechanism and a rotating mechanism are sequentially arranged on the N-shaped frame 1 from top to bottom. Fixing mechanism comprises bracing frame 2, connecting plate 3, fixed cylinder 4 and pressing plate 5, and described bracing frame 2 is located on the N-shaped frame 1, and the crossbeam lower surface of described bracing frame 2 is fixedly provided with connecting plate 3, in The lower surface of the connecting plate 3 is provided with a fixed cylinder 4, the piston rod of the fixed cylinder 4 is connected with the pressure plate 5, the composite plate to be cleaned is placed on the rotating mechanism, and then the fixed cylinder 4 is started, and the pressure plate 5 is pressed on the Composite board can be,

[0024] The clearing mechanism include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com