Track plate automatic production line

An automatic production line and track plate technology, which is applied in ceramic molding workshops, ceramic molding machines, manufacturing tools, etc., to avoid returning, reduce labor input, and simplify the process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

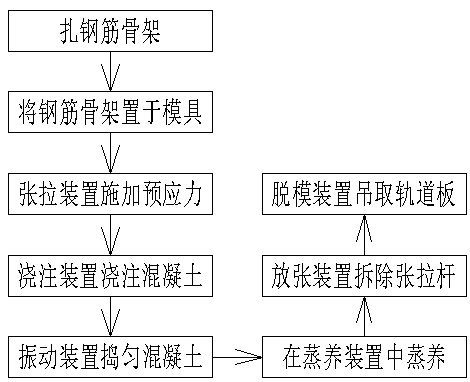

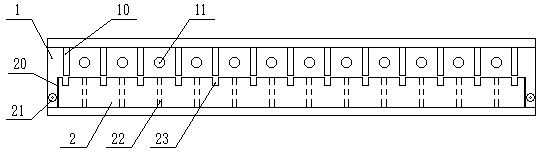

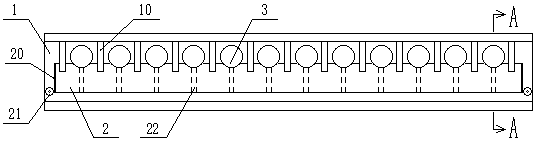

[0017] like figure 1 The track slab automatic production line shown includes track slab molds, transfer devices, and stretching devices, pouring devices, vibration devices, steam curing devices, tensioning devices and demoulding devices arranged in sequence along the transfer devices. The entire production line requires After binding the steel frame, then put the tied steel frame into the track plate mold. The transfer device includes a transfer trolley and a transfer track. The track plate mold is placed on the transfer trolley, and the transfer trolley drives the track plate mold to the tensioning device. Apply prestress to the steel bars, and then turn the pouring device to pour concrete into the track slab mold. At the same time, the vibrating device works to make the concrete evenly distributed in the track slab mold to avoid air bubbles. After the pouring is completed, transfer it to the steam curing device for steam curing. After the steam curing is completed, it is tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com