Method for extracting and purifying electronic grade hexachlorodisilane and extractive distillation system

A hexachlorodisilane, extraction and rectification technology, applied in halosilane, chemical instruments and methods, silicon compounds, etc., can solve the problems of insufficient purity, high cost, and difficult separation, and achieve low separation difficulty coefficient and low energy consumption The effect of low consumption and low difficulty coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] 1. Extraction and purification method of electronic grade hexachlorodisilane and extractive distillation system

[0068] Trimethylchlorosilane was selected as the low-density extractant A with a boiling point of 57.7°C at normal pressure, and germanium tetrachloride was selected as the high-density extractant B with a boiling point of 83.1°C at normal pressure to extract and purify hexachlorodisilane. The specific steps were as follows:

[0069] Step 1: No. 1 rectification tower unit is used to remove low-boiling impurities in hexachlorodisilane.

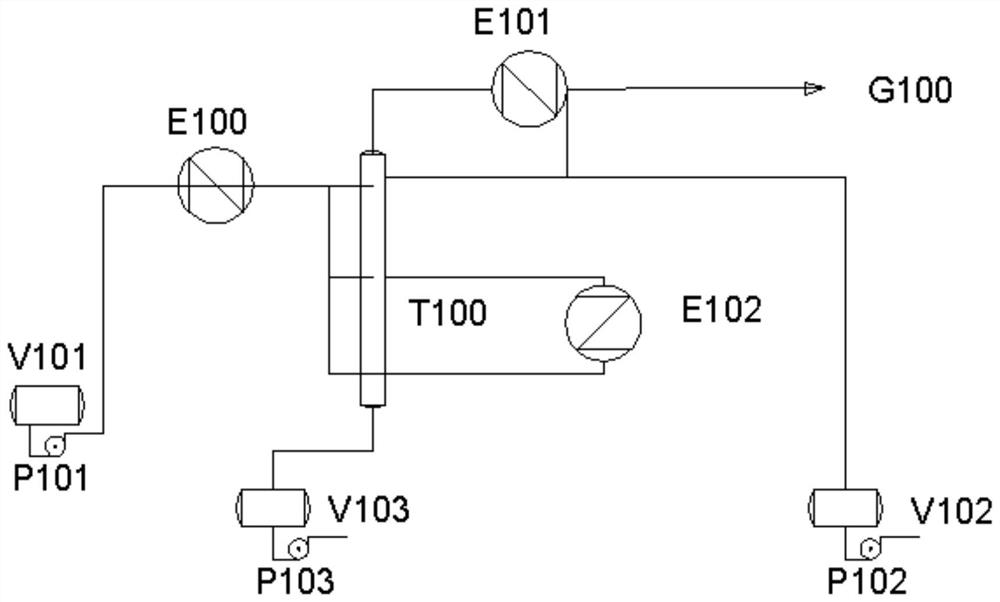

[0070] Such as figure 1 Shown: T100 is the rectification tower No. 1, E100 is the preheater of the rectification tower No. 1, E101 is the condenser of the rectification tower No. 1, E102 is the reboiler of the rectification tower No. 1, and V101 is the raw material of hexachlorodisilane tank, P101 is the conveying pump for the hexachlorodisilane raw material tank, V102 is the discharge tank for the top of the No. 1 rectifica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com