Vehicle-mounted pavement crack detection system inspection device based on belt transmission

A crack detection and inspection device technology, applied to measuring devices, instruments, etc., to achieve reliable performance, stable transmission, and low operating noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing, the present invention is described in further detail:

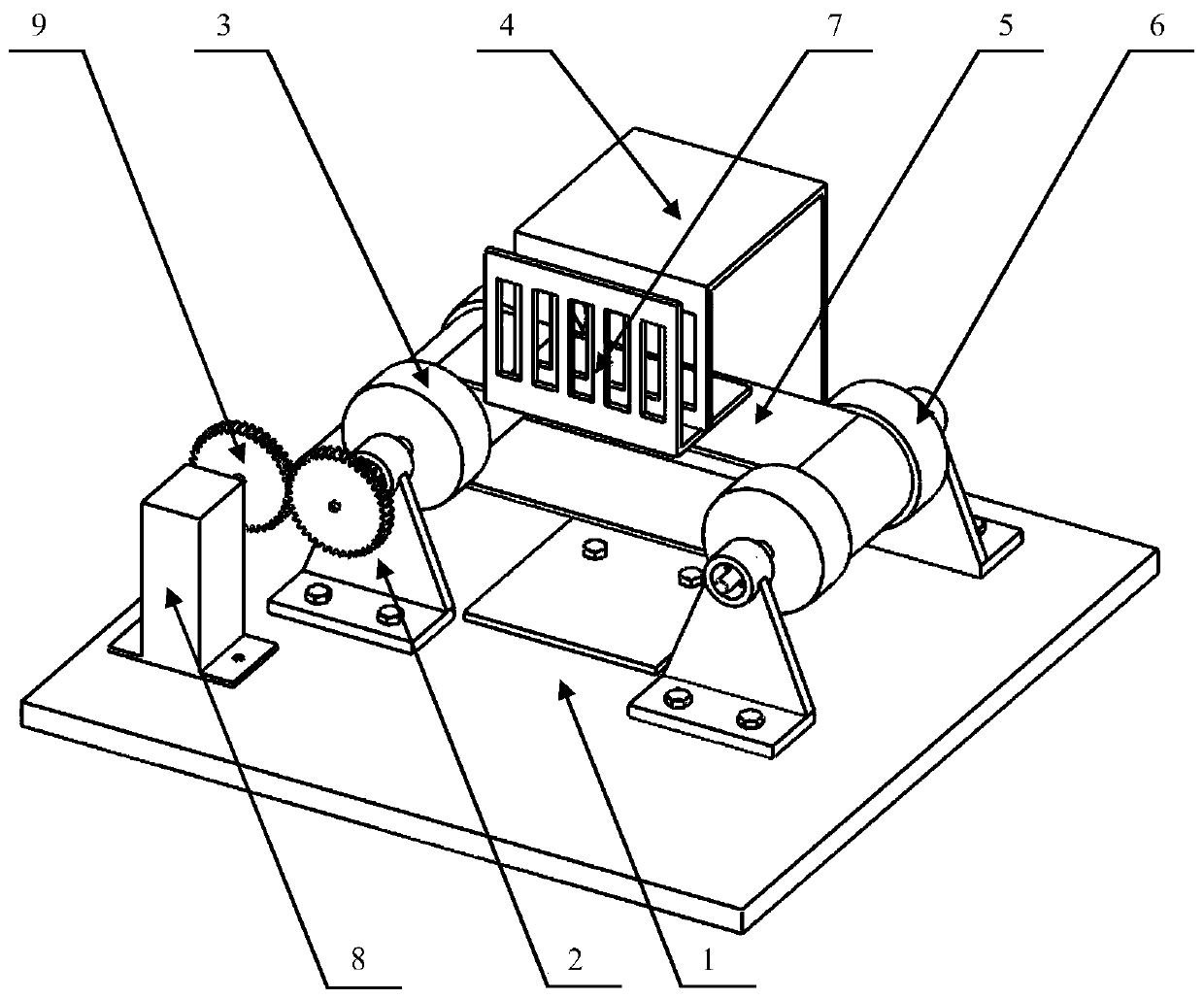

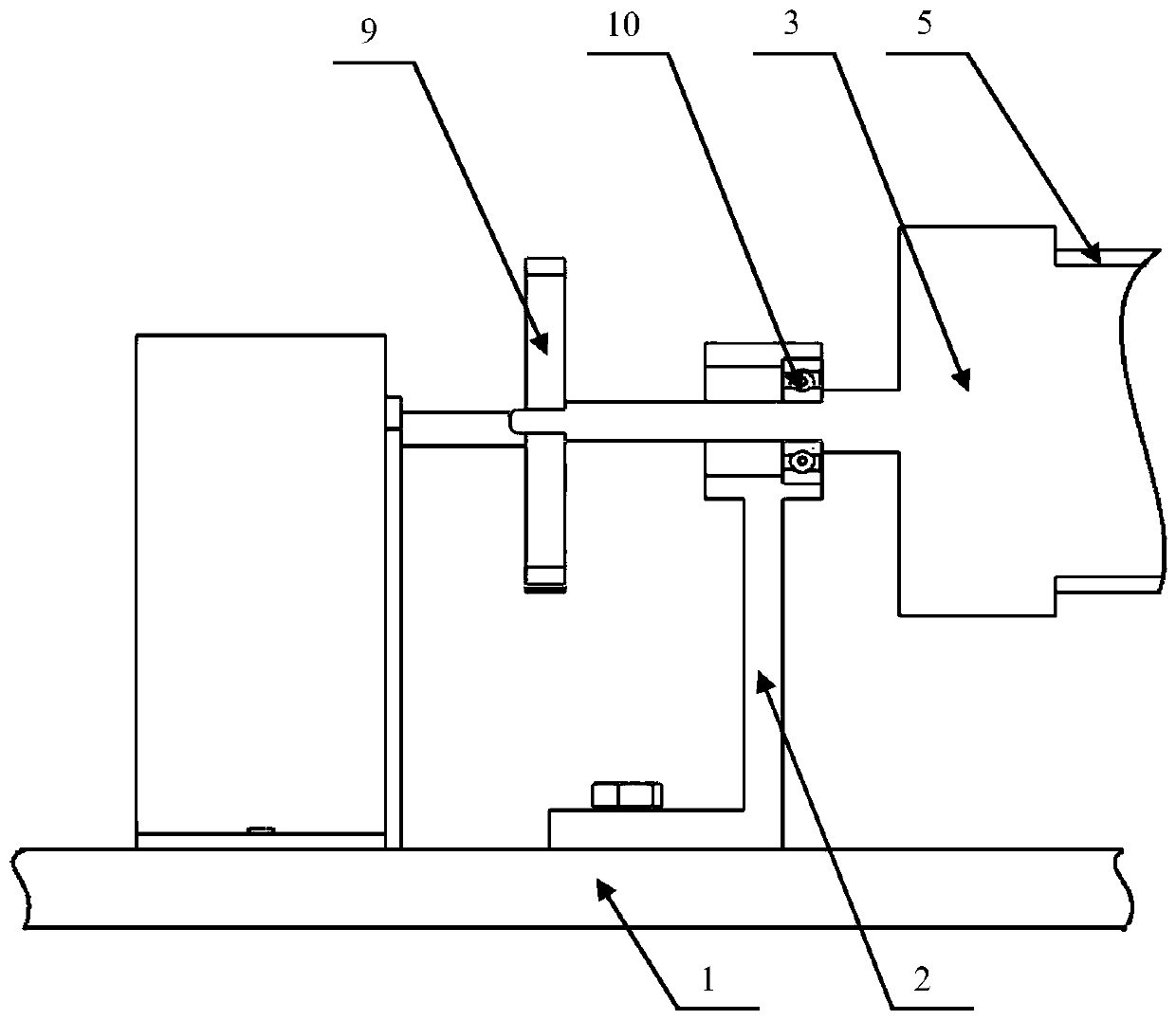

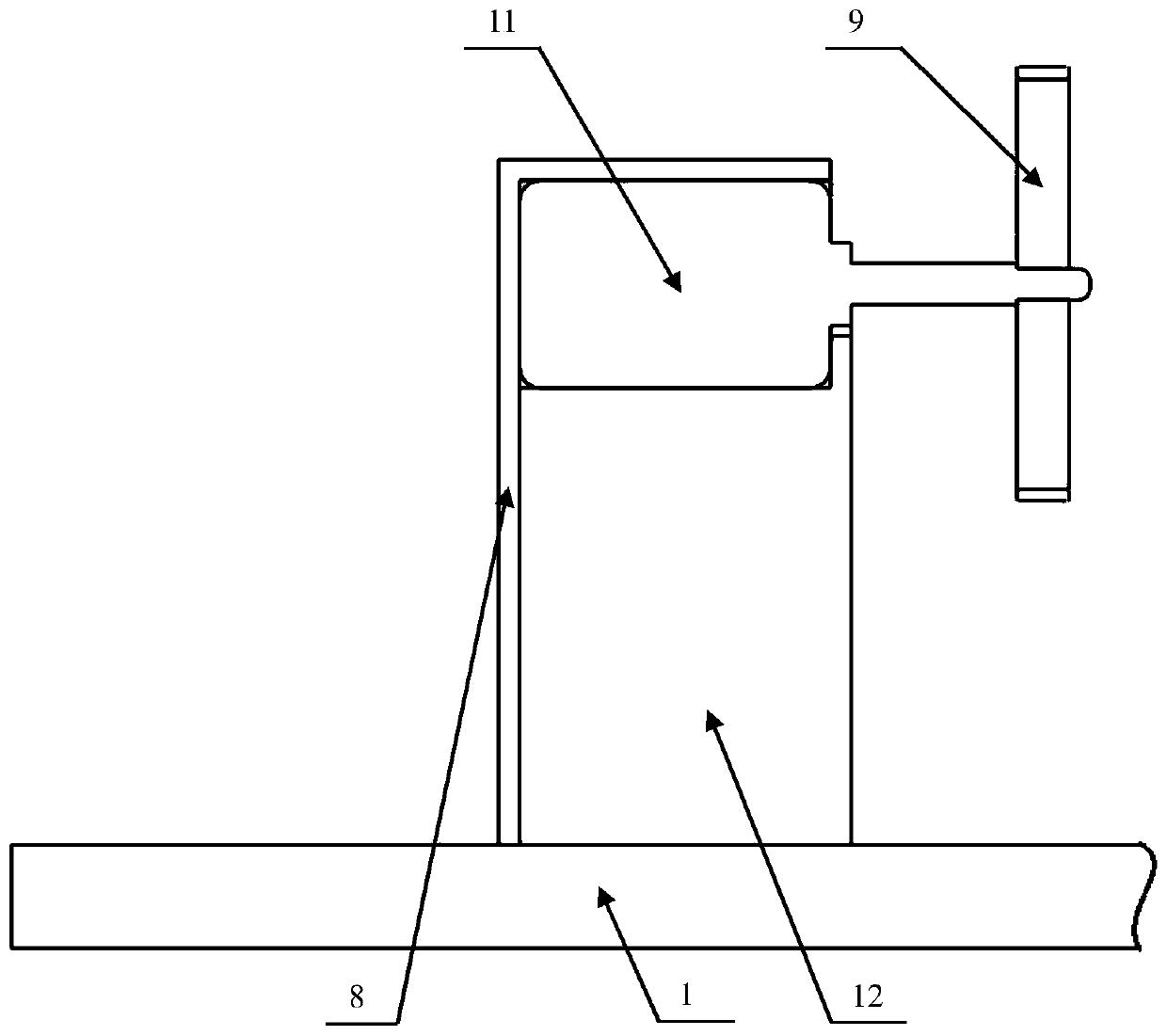

[0030] refer to Figure 1 to Figure 11 The inspection device of the vehicle-mounted road surface crack detection system based on belt transmission includes a base 1, a bearing seat 2, a driving wheel 3, a motherboard 4, a transmission belt 5, a driven wheel 6, a sub-board 7, a motor cover 8, a gear 9, a bearing 10, Motor 11 and motor base 12.

[0031] The base 1 is a rectangular part processed from a steel plate, with threaded holes processed on the surface, and the base 1 is placed on a level ground. The bearing seat 2 is a part welded by a rectangular steel plate at the bottom, a triangular steel plate at the middle and a cylinder at the top. The rectangular steel plate at the bottom is processed with two round holes, and the cylinder at the top is processed with stepped holes. The driving wheel 3 is a part welded by a steel stepped cylinder in the middle, circular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com