Annular wrapping dust suppression device for tunneling machine

A roadheader and ring-shaped technology, which is applied in the field of dust control of dust sources at the cutting head of underground roadheaders in coal mines, can solve dust removal problems and other problems, and achieve the effect of convenient operation and optimized dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

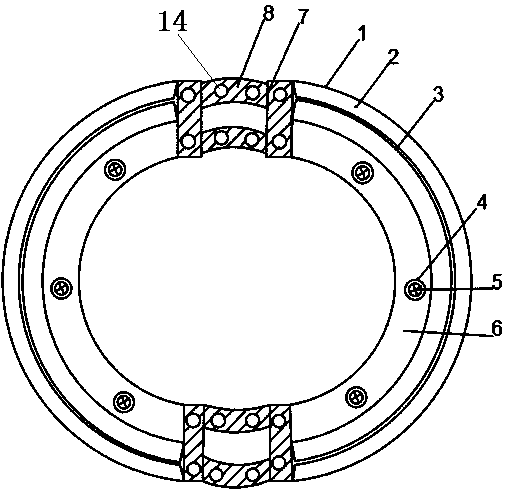

[0018] Such as figure 1 As shown, a ring-wrapped dust suppression device for a roadheader of the present invention is formed by connecting two semicircular jet flow devices through connecting pieces.

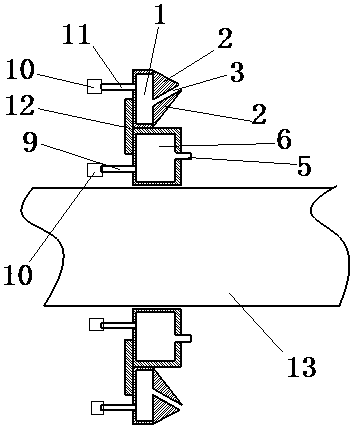

[0019] The semi-circular jet flow device comprises an air flow chamber 1, an air guide wall 2, a jet atomizing nozzle 5, a water flow chamber 6 and a fixed base plate 12, the air flow chamber 1 is arranged on the outside of the water flow chamber 6, and the shell of the air flow chamber 1 is in contact with the water flow The shell of the chamber 6 is connected or connected by a fixed bottom plate 12 to form a circular ring; six jet atomizing nozzles 5 are arranged equidistantly in front of the water flow chamber 6, and a water inlet pipe 11 is arranged behind the water flow chamber 6, and the water inlet pipe 11 is connected to the quick connector 10, The j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com