Nanometer precision detection method and device of free curved surface morphology

A precision detection and free technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of insufficient measurement accuracy, limited free-form surface profile measurement accuracy, and inability to overcome the characteristics of sample surface roughness, undulation, inclination angle and other problems. , to achieve the effect of improving accuracy, improving detection accuracy and speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

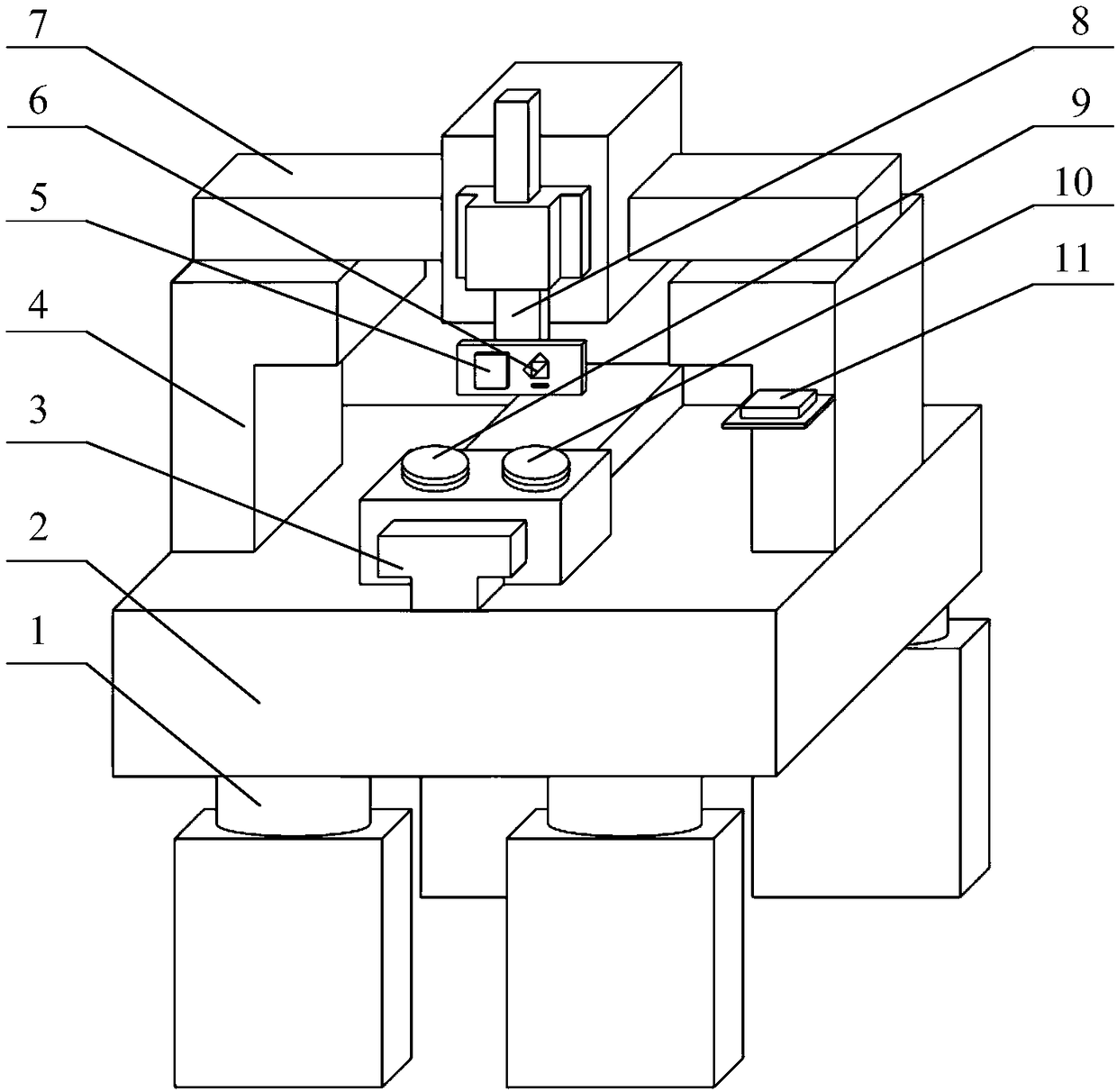

[0034] Such as figure 1 with figure 2 As shown, the device of the present invention includes: an active air-floating vibration isolation spring, an air-floating vibration isolation base, an X-direction air-floating guide rail, a gantry, a laser differential confocal fixed-focus trigger measurement system, a laser interference displacement measurement mirror group, Y-direction air bearing guide rail, Z-direction air bearing guide rail, free-form surface sample attitude adjustment device, reference flat crystal attitude adjustment device, laser interferometer;

[0035] Free-form surface shape nanometer precision detection method, the detection steps are as follows:

[0036] Step 1: Place the high-precision flat crystal on the free-form surface sample attitude adjustment device 9 and the reference flat crystal attitude adjustment device 10 respectively, and measure the distance between the laser interferometer mirror group 6 and the high-precision flat crystal through the laser inter...

Embodiment 2

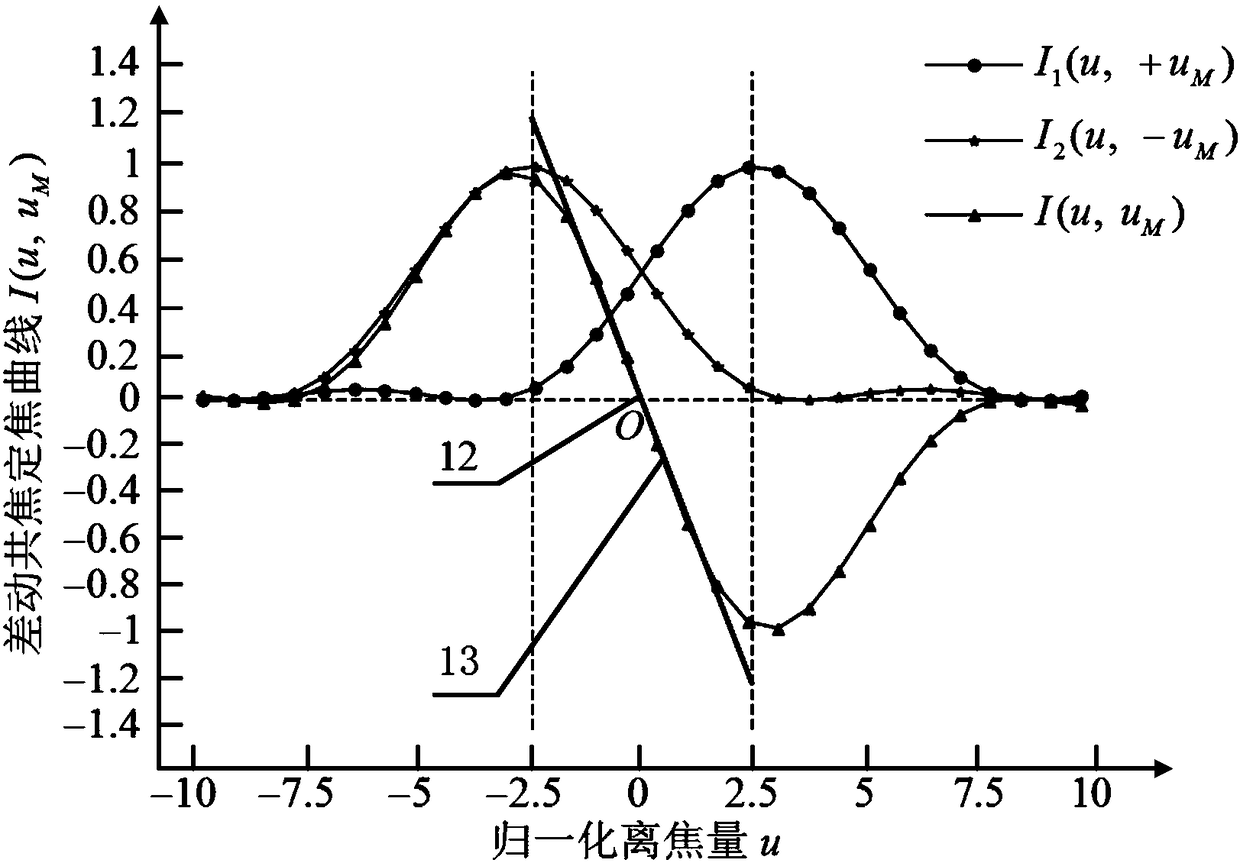

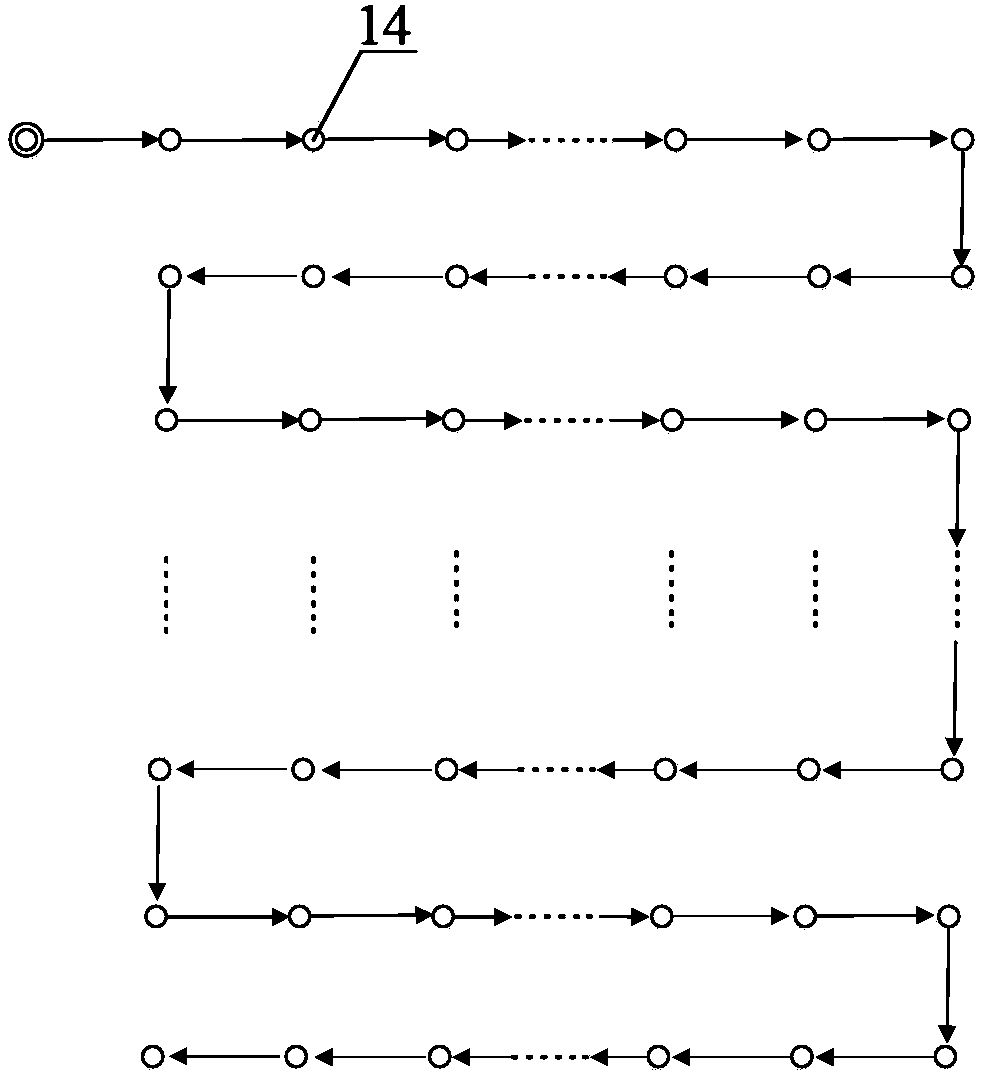

[0041] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, the nanometer precision detection method of free-form surface shape, the detection steps are as follows:

[0042] Step 1: Place the high-precision flat crystal on the free-form surface sample attitude adjustment device 9 and the reference flat crystal attitude adjustment device 10 respectively, and measure the distance between the laser interferometer mirror group 6 and the high-precision flat crystal through the laser interferometer 11 , Adjust the posture of the free-form surface sample attitude adjustment device 9 and the reference flat crystal attitude adjustment device 10 to ensure that it is perpendicular to the Z-direction air bearing guide 8;

[0043] Step 2: Place the tested free-form surface sample and high-precision flat crystal on the free-form surface sample attitude adjustment device 9 and the reference flat crystal attitude adjustment device 10 respectively, and use the Z-direction air bearing g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com