Simulation method of oil and gas pipeline welding joint inner crack expanding based on fluid and solid magnetic multi-field coupling

A technology of oil and gas pipelines and simulation methods, applied in design optimization/simulation, special data processing applications, instruments, etc., can solve problems not involved in crack detection in pipeline welds and fluid-solid-magnetic multi-field coupling technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

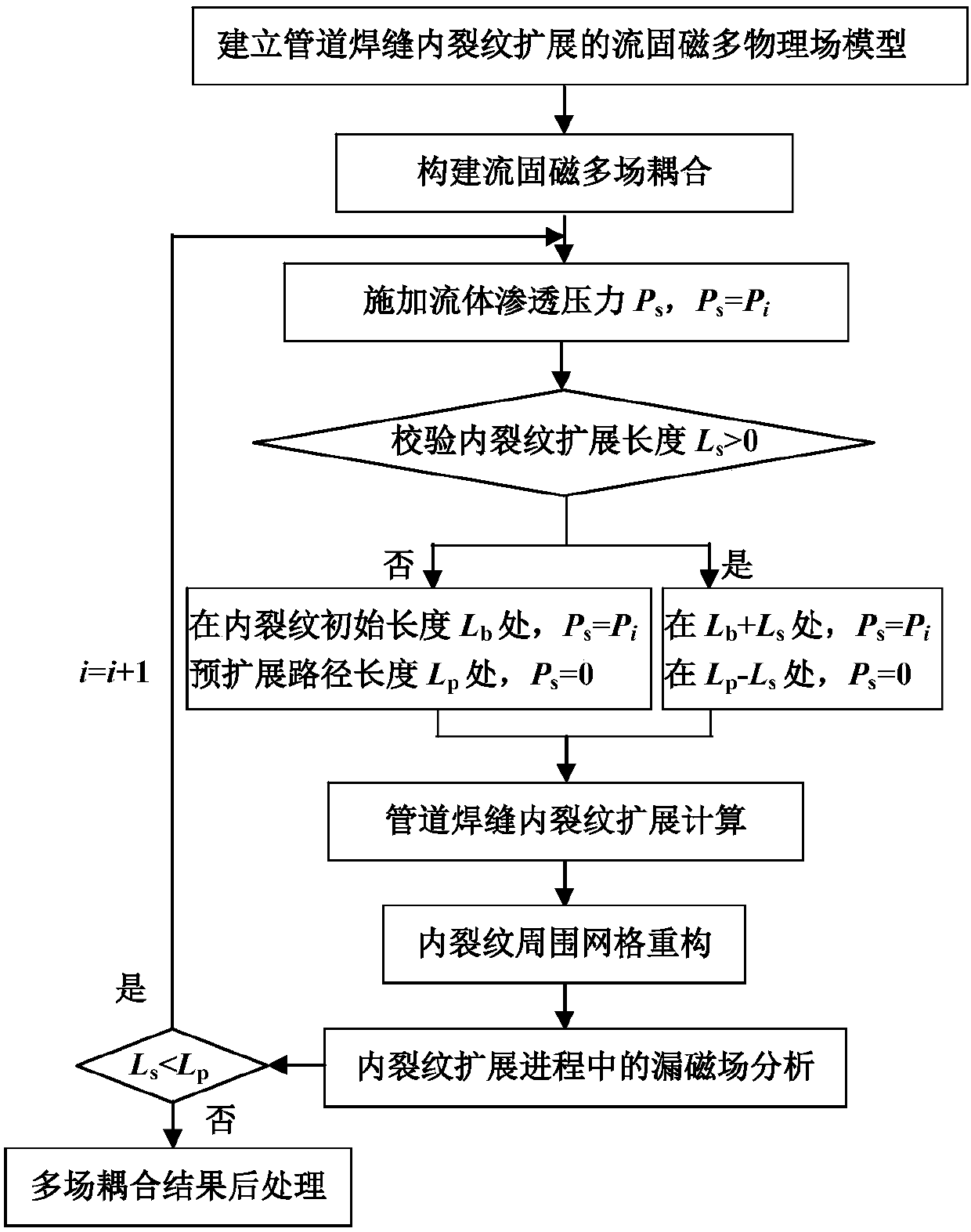

[0083] The flow chart of the simulation method for crack propagation in oil and gas pipeline welds based on fluid-solid-magnetic multi-field coupling is shown in Fig. figure 1 Shown, the present invention will be further described below in conjunction with flowchart and other accompanying drawings:

[0084] Step 1. Establishing a fluid-solid magnetic multi-physics model of crack propagation in pipeline welds;

[0085] (1) Construct the structural model of the pipeline weld;

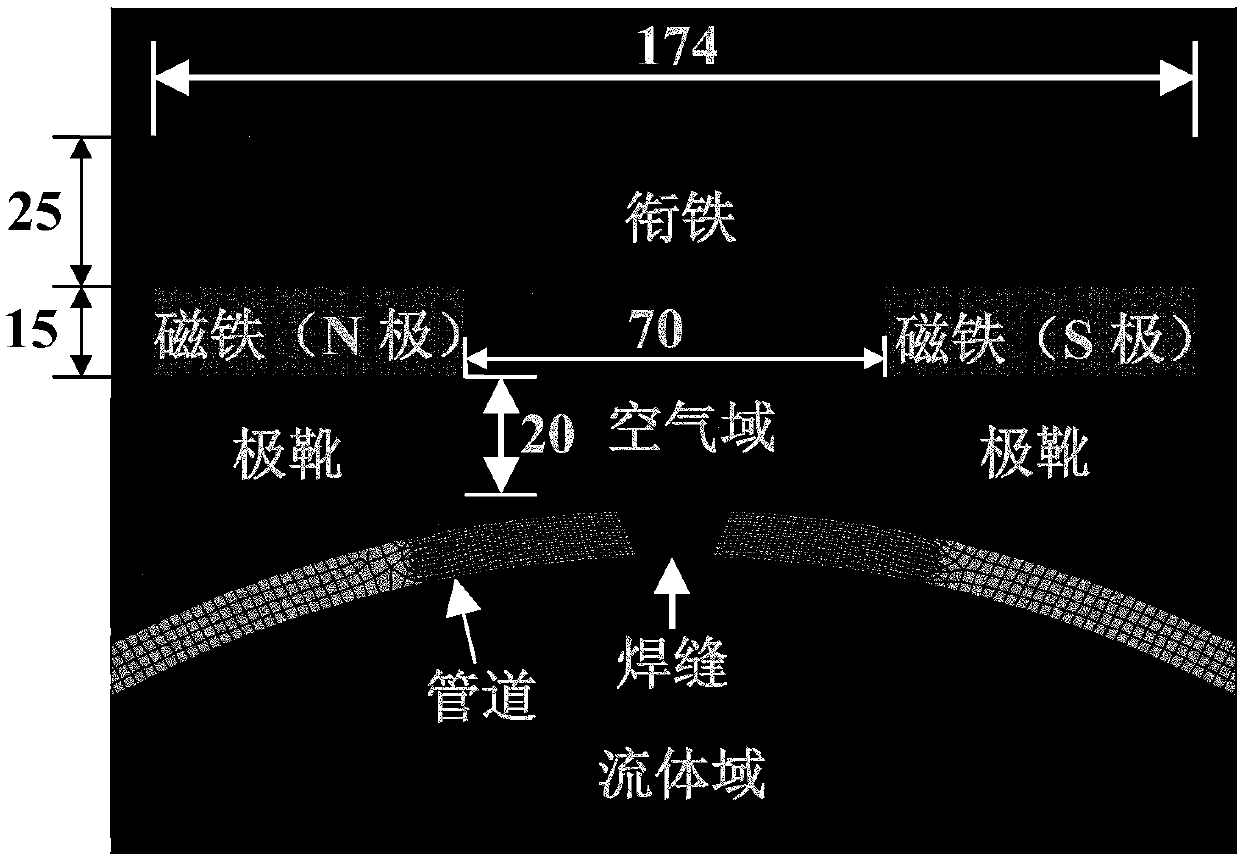

[0086] a. According to the pipe specification φ400mm×8mm, material Q235, and weld reinforcement 2mm, select the plane strain model and the two-dimensional PLANE182 structural unit in the finite element software ANSYS to establish the structural stress analysis model of the pipe weld;

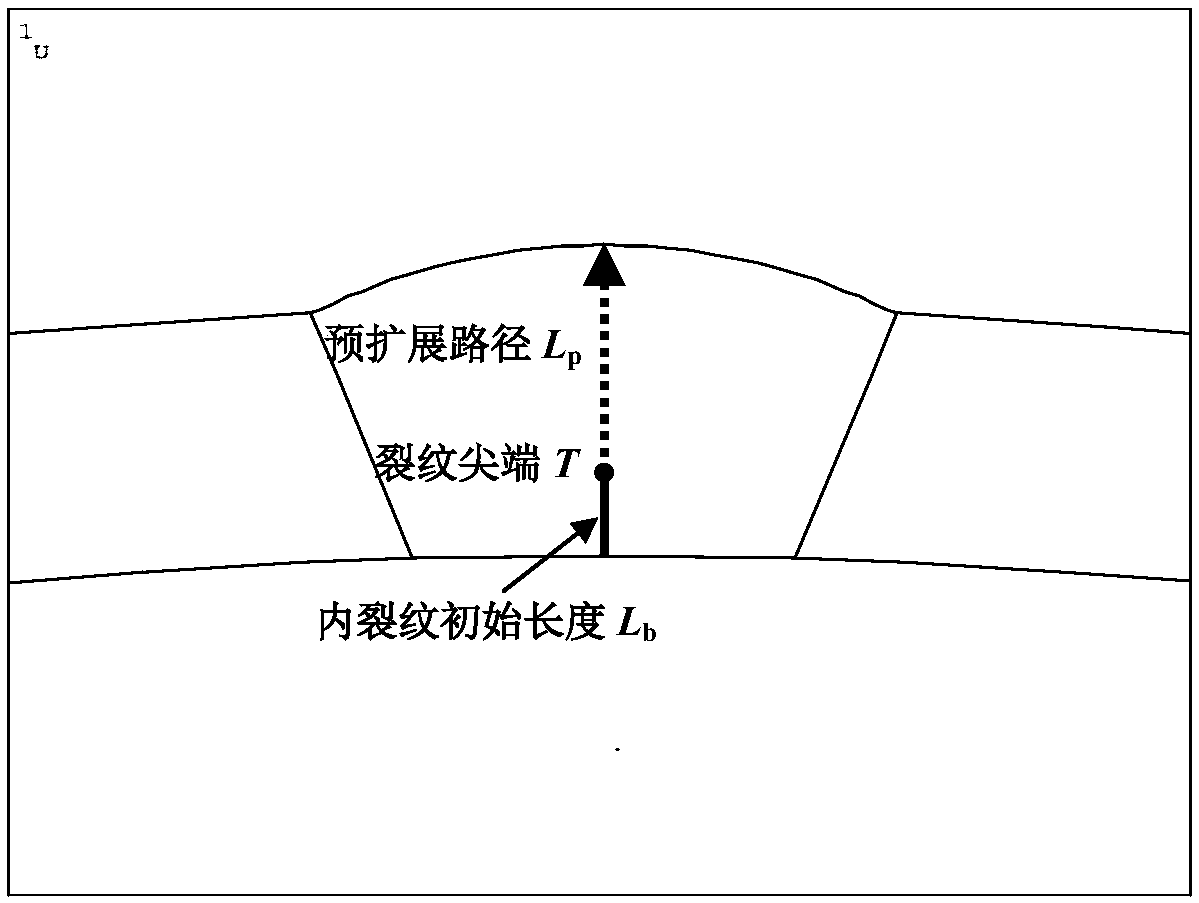

[0087] b. Taking the distribution of cracks along the radial inner wall at the center of the pipe weld as an example, the initial internal cracks are predefined. The initial length of the internal crack L b = 2mm, specif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com