Mobile phone screen and manufacturing method thereof

A manufacturing method and technology of mobile phone screens, which are applied in the fields of telephone structure, optics, telephone communication, etc., can solve the problems of reducing user experience satisfaction, increasing light loss and reflection, and reducing color contrast, so as to improve experience satisfaction, improve Contrast, inexpensive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

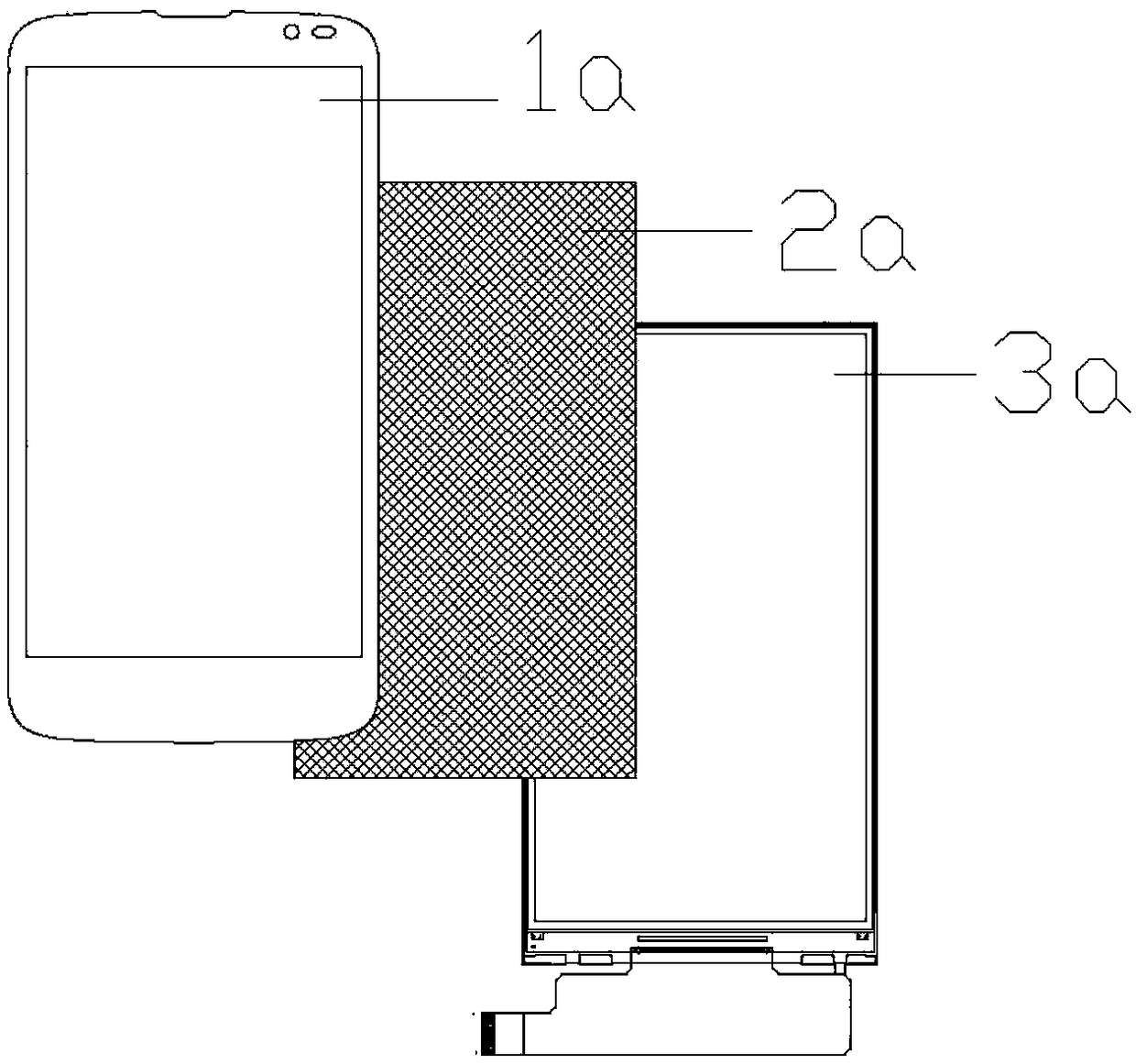

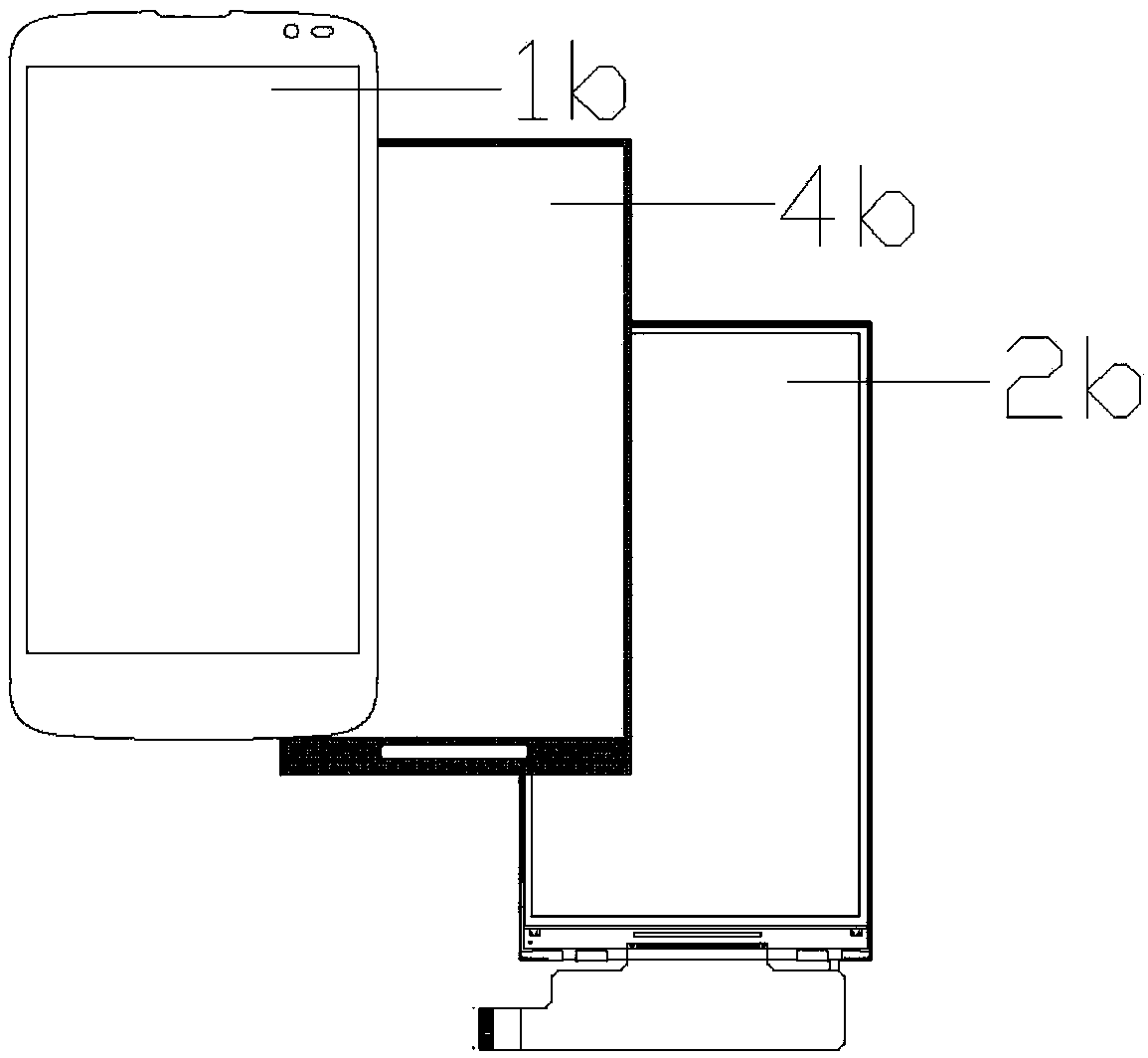

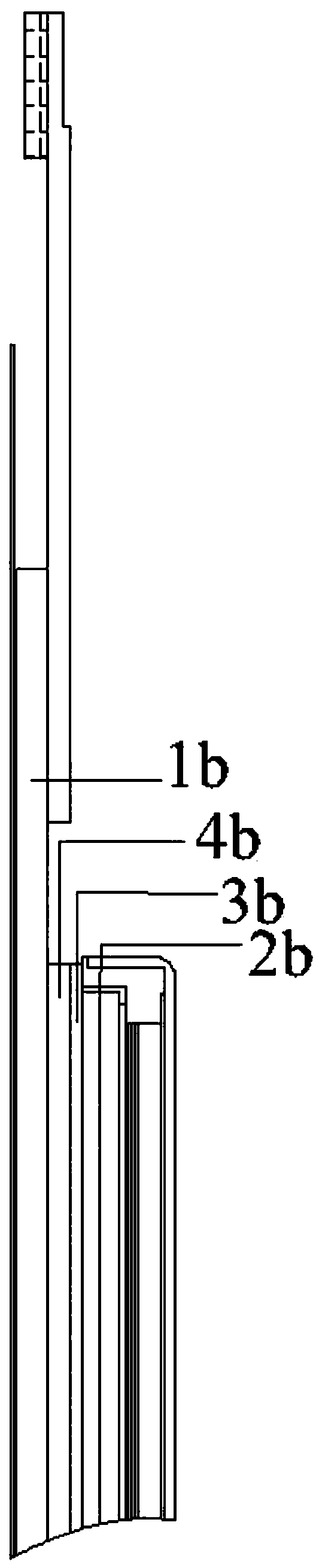

[0033] A mobile phone screen, comprising a touch screen 1 and a display screen 2, the display screen 2 includes an upper polarizer 3 and an LCD, the LCD includes a CF substrate 4 and a TFT substrate 5, the upper polarizer 3 is glued on one side, the The glued side of the upper polarizer 3 is bonded to the touch screen 1, and the non-glued side of the upper polarizer 3 is bonded to the CF substrate 4 of the LCD through the foam 6. In order to avoid the display area, the foam 6 6 is hollowed out in the shape of a square, and is in contact with the upper polarizer 3 and the CF substrate 4 only through the surrounding edges.

[0034] In the mobile phone screen of the present invention, the glued side of the upper polarizer 3 is bonded to the touch screen 1, so that there is no air medium layer between the upper polarizer 3 and the touch screen 1. According to the principle of liquid crystal display, the displayed image seen by the human eye is actually It is formed by the polarize...

Embodiment 2

[0041] A method for manufacturing a mobile phone screen, comprising the following steps:

[0042] (1) Provide an upper polarizer 3 with glue on one side, and the incoming angle deviation of the upper polarizer 3 is controlled within ±0.5°;

[0043] (2) The glued side of the upper polarizer 3 is bonded to the touch screen 1, and the angle deviation between the upper polarizer 3 and the touch screen 1 is controlled within ±0.5°;

[0044] (3) The touch screen 1 is bonded to the CF substrate 4 of the LCD through the foam 6 arranged on the non-adhesive side of the upper polarizer 3, and the deviation of the bonding angle between the touch screen 1 and the LCD is controlled within ±0.5°, and The deviation of the bonding angle between the upper polarizer 3 and the LCD after the final bonding is controlled within ±2°.

[0045] In the mobile phone screen of the present invention, the glued side of the upper polarizer 3 is bonded to the touch screen 1, so that there is no air medium la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com