Multiaxial-inlay knitted fabric base material production method, multiaxial-inlay knitted fabric base material, and fiber-reinforced composite material

A manufacturing method and multi-axial technology, applied in the directions of non-woven fabrics, warp knitting, textiles and papermaking, etc., can solve the problems of reduced strength and elastic modulus of formed parts, and reduced surface smoothness of formed parts. High volume, good surface smoothness, small mesh effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

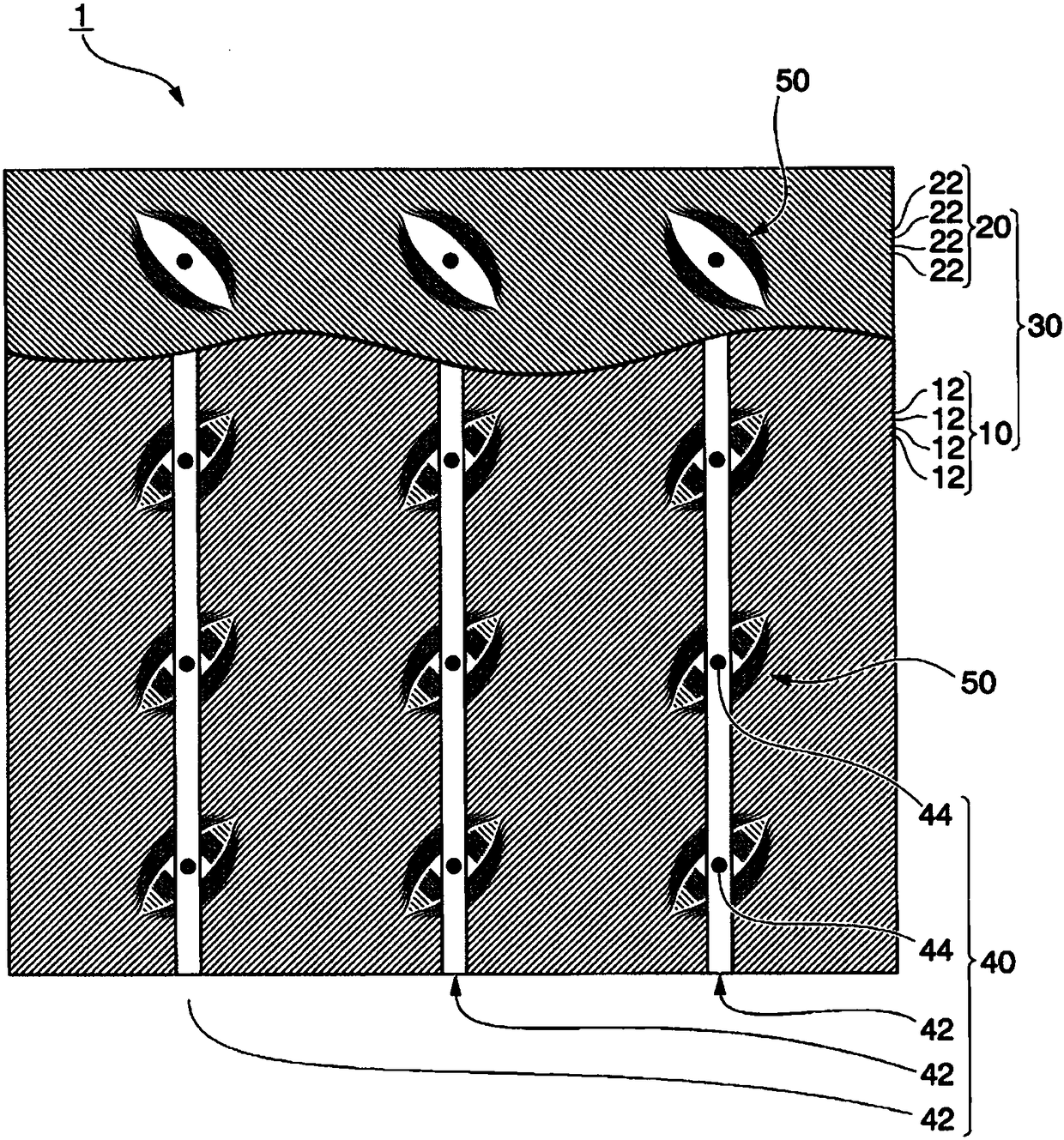

[0124] As the reinforcing fiber, carbon fiber (manufactured by Mitsubishi Rayon Co., Ltd., Pyrofil (Pyrofil, registered trademark) TRW40 50L) was used, and the basis weight of the reinforcing fiber was 150 g / m 2 The reinforced fiber sheet is made of a plurality of reinforced fibers along one axial direction.

[0125]The two obtained reinforcing fiber sheets are stacked such that the axial directions of the reinforcing fibers are orthogonal to each other to form a multiaxial stack.

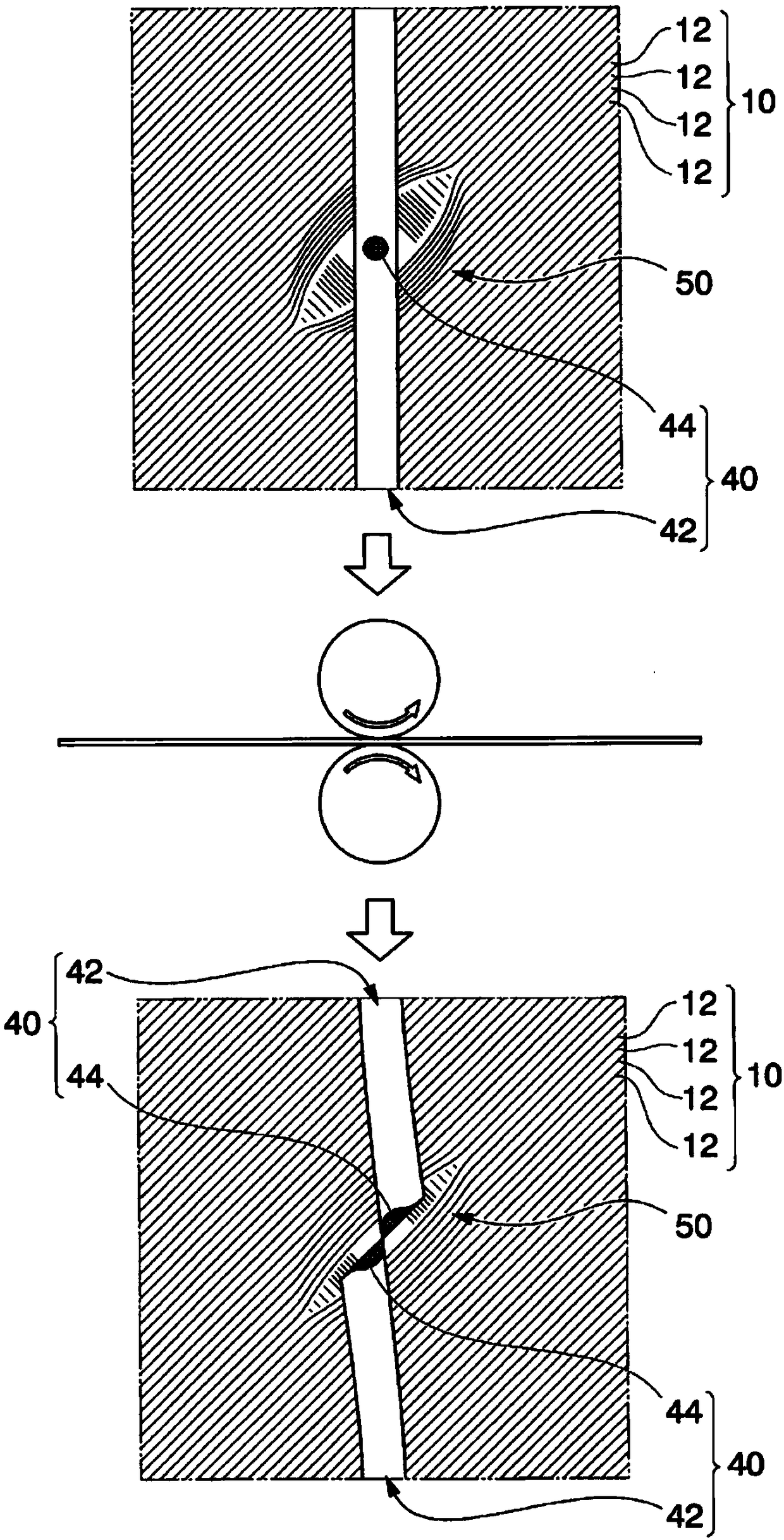

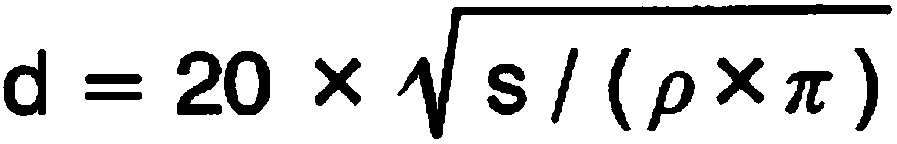

[0126] Braided polyester thread (manufactured by Tenzler GmBH, dtex78f36text.roh halbmatt, 78dtex, 36F (filament), glass transition temperature 80°C, melting point 220°C, density 1.4g / cm 3 , the nominal diameter of 84.2μm) of the chain knitted structure of the restraining braid, the direction of the reinforcing fibers is +45° / -45° with respect to the reference direction of the multi-axial insertion braid base material to constrain the multi-axial stacks, making them all together to make things lik...

Embodiment 2

[0133] A multiaxial insert knitted fabric base material was obtained in the same manner as in Example 1, except that a single-bar warp knitted constrained knitted fabric was used as the constrained knitted fabric.

[0134] The width of the mesh of the resulting multiaxially inserted woven fabric substrate was 37.3 μm.

Embodiment 3

[0139] A multiaxially inserted knitted fabric base material was obtained in the same manner as in Example 1, except that the load line load in the rolling process was set to 30 N / cm.

[0140] The width of the mesh of the resulting multiaxially inserted woven fabric substrate was 58.3 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com