Small-sized bent glass washing machine

A glass cleaning and small-scale technology, which is applied in the direction of dryers, cleaning flexible objects, cleaning methods and utensils, etc., can solve the problems that curved glass cannot be cleaned, achieve excellent air-drying effect and improve cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Attached below Figure 1-6 The preferred embodiments of the present invention are described in detail, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

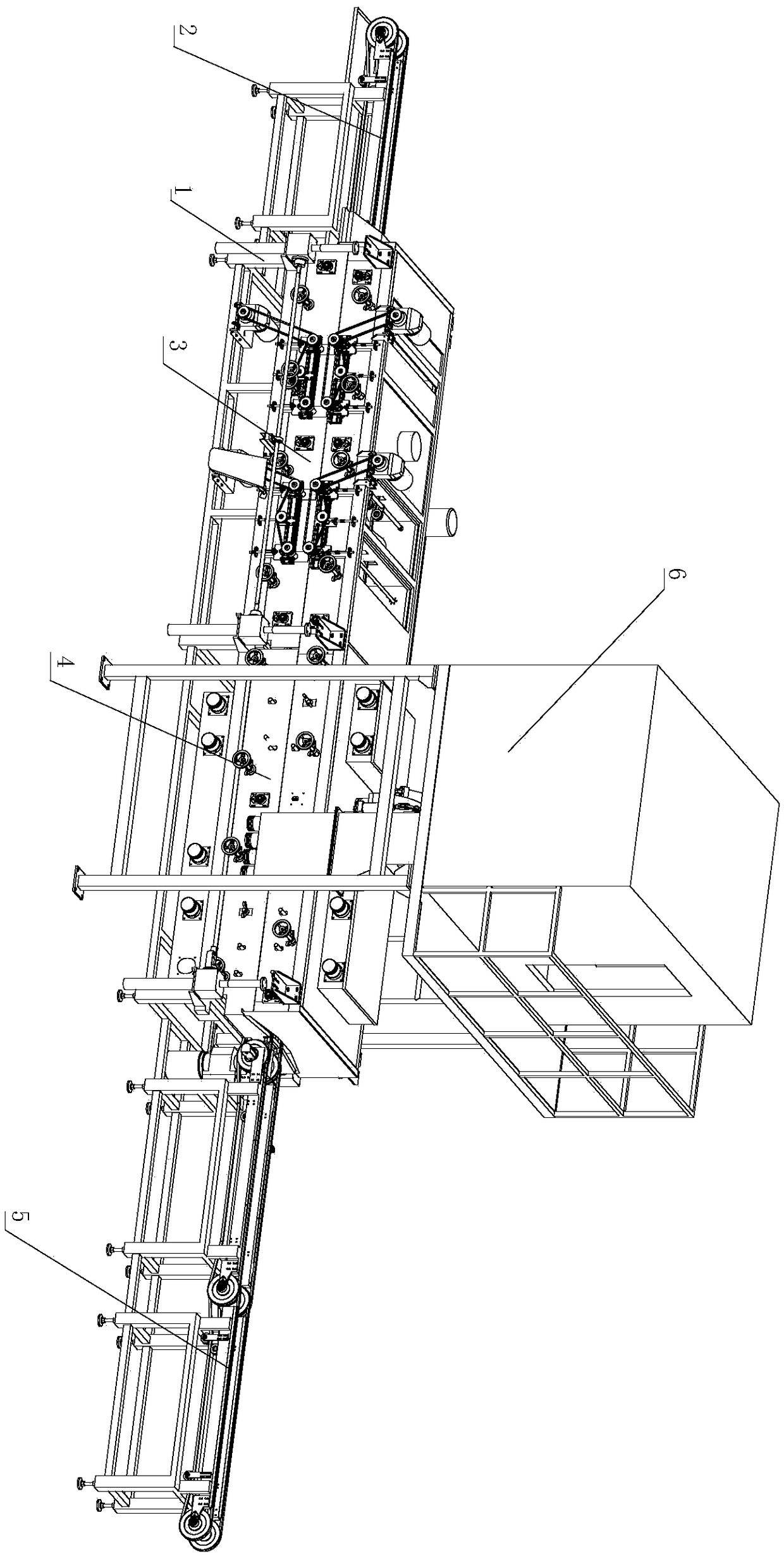

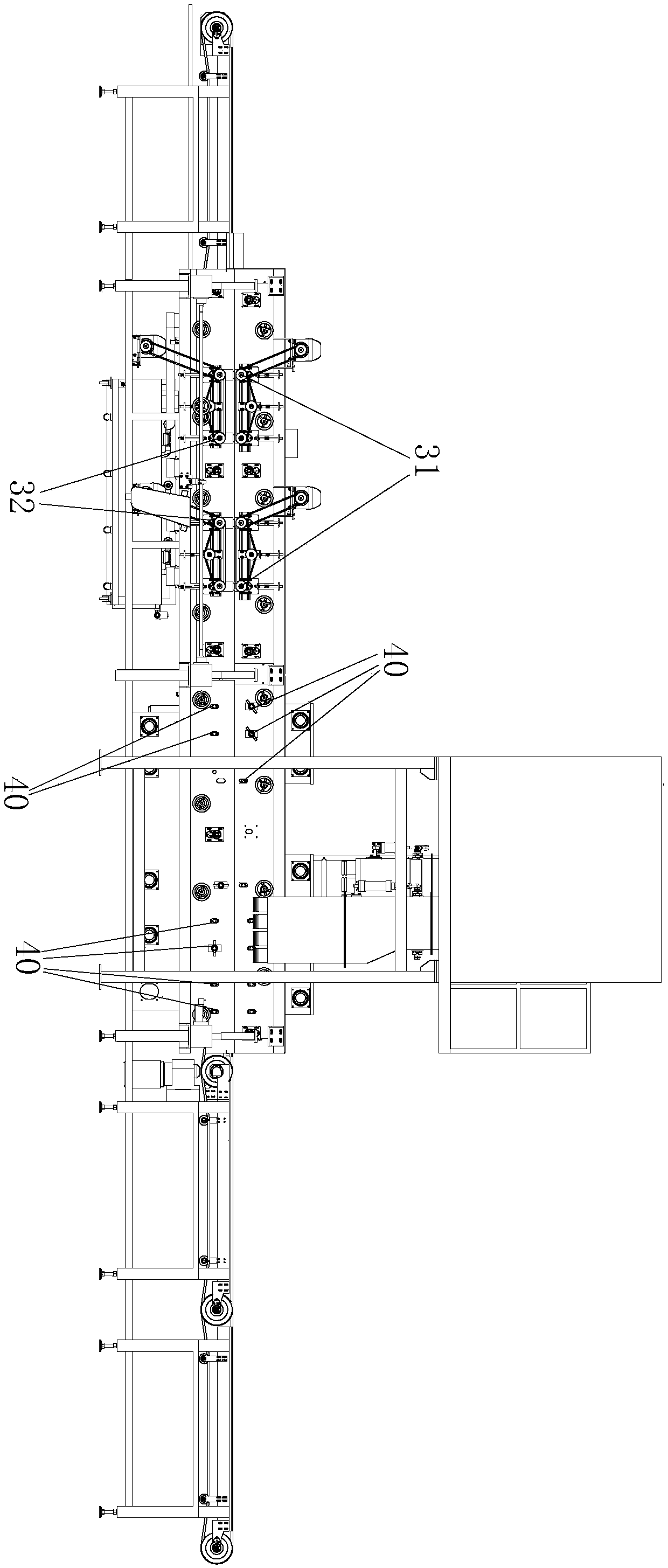

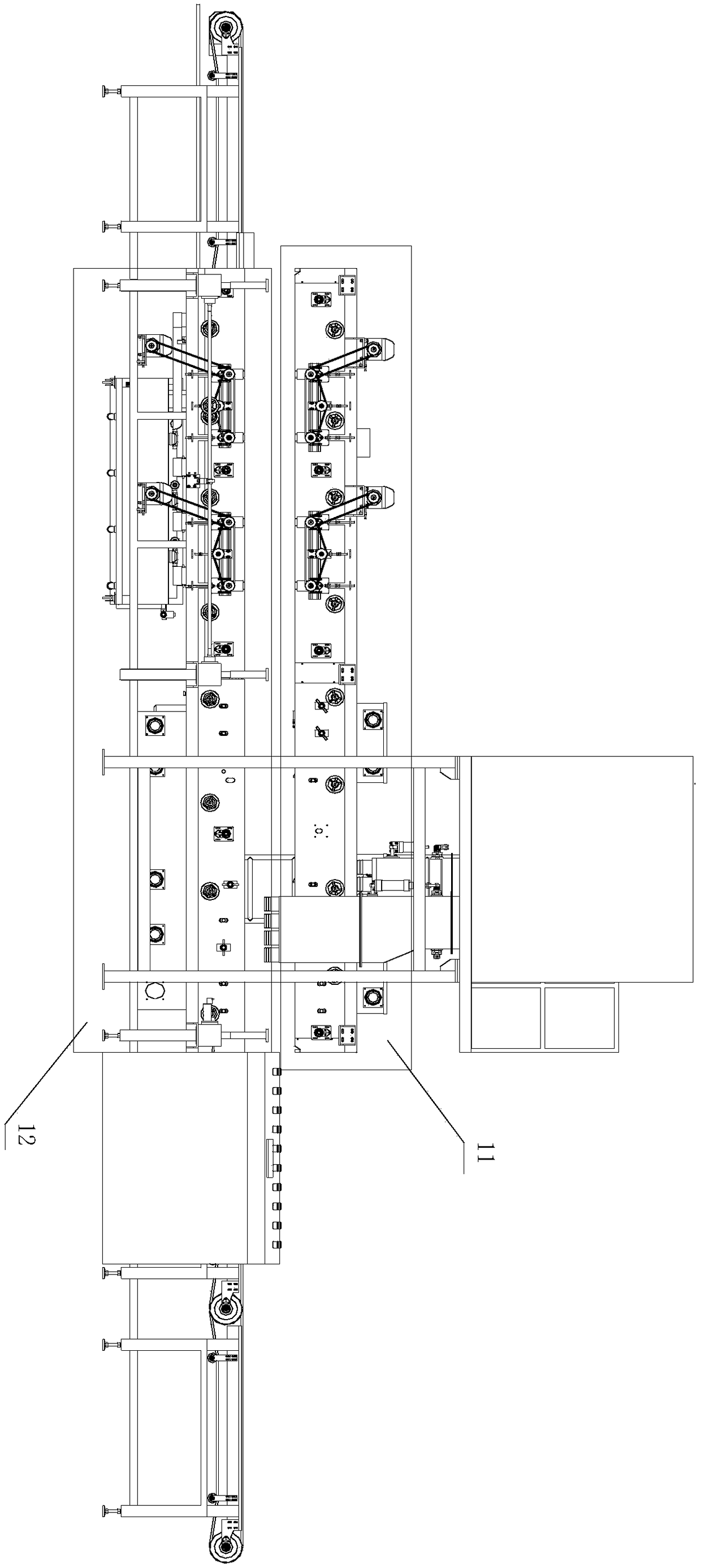

[0022] Such as figure 1 , figure 2 , image 3 Shown, a kind of small-sized curved glass washing machine comprises frame (1) for carrying and enters section (2), hairbrush cleaning section (3), air-drying section (4), goes out section (5), described The inlet section (2) for carrying glass into the brush cleaning section (3) is connected to the brush cleaning section (3), and the brush cleaning section (3) includes a rolling brush cleaning part and a water tank part, and the bottom of the water tank part The rollers are placed on the side of the cleaning part of the roller brush, which is convenient to be pulled out for cleaning. The cleaning part of the roller brush and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com