Multistage pulse control method for thermal power plant regulation valve

A technology of pulse control and regulating valve, which is applied in the direction of valve operation/release device, valve details, valve device, etc., can solve the problems of undisclosed multi-stage pulse control method, etc., achieve excellent dynamic response ability, easy engineering realization, on-site Simple effect of parameter debugging process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and through the examples. The following examples are to explain the present invention and the present invention is not limited to the following examples.

[0022] Example.

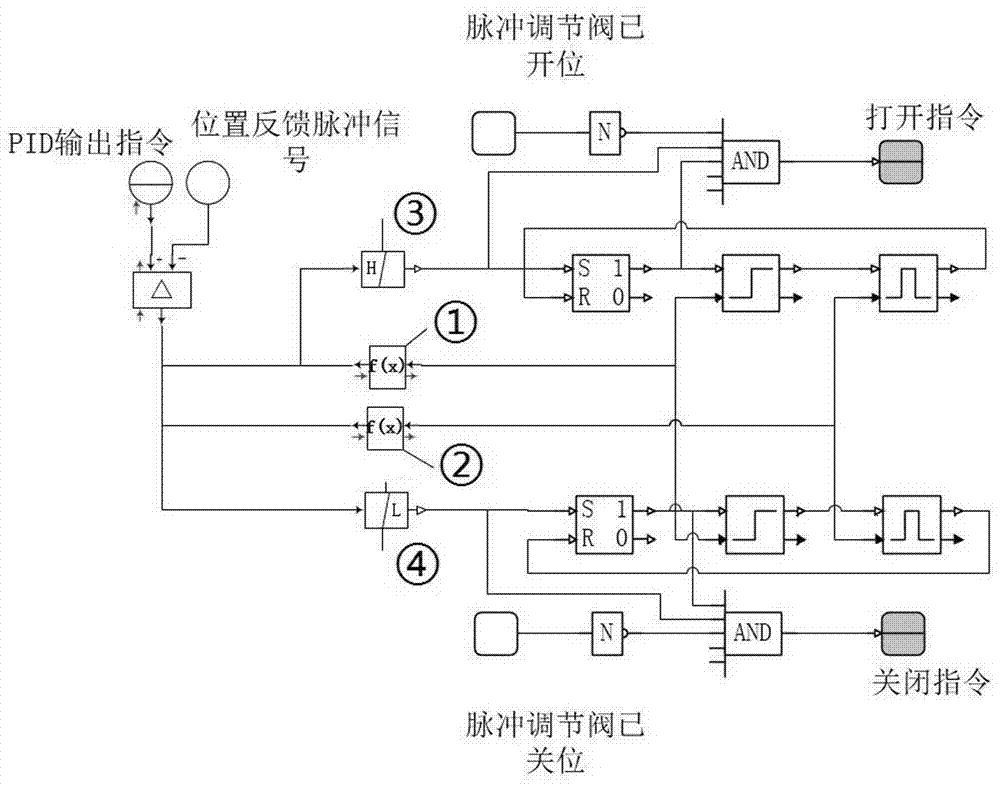

[0023] see figure 1 .

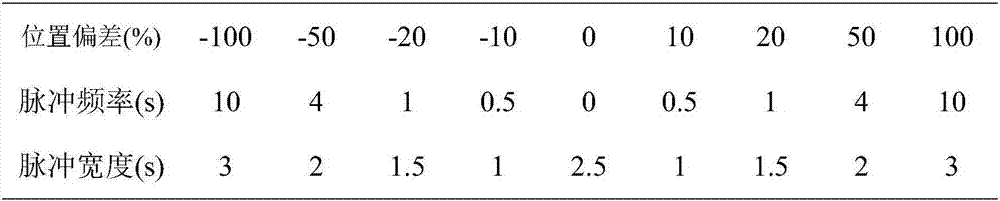

[0024] This embodiment is a multi-stage pulse control method for a control valve in a thermal power plant. At the beginning of each switching cycle, the regulator automatically detects the position state of the pulse control valve, and controls the error between the output command and the position feedback signal according to the current PID control. Select one of the multi-level pulses as the effective control signal of the cycle. In this control method, switching pulses at different levels with different duty ratios are set according to the regulator topology and parameters, and these control pulses with different strength levels form a pulse sequence to realize t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com