Roller can ear rubber wheel reinforcement hoop processing equipment

A processing equipment and roller can ear technology, which is applied in the field of roller can ear rubber wheel reinforcement hoop processing equipment, can solve the problems of poor welding accuracy, high rejection rate, large welding deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

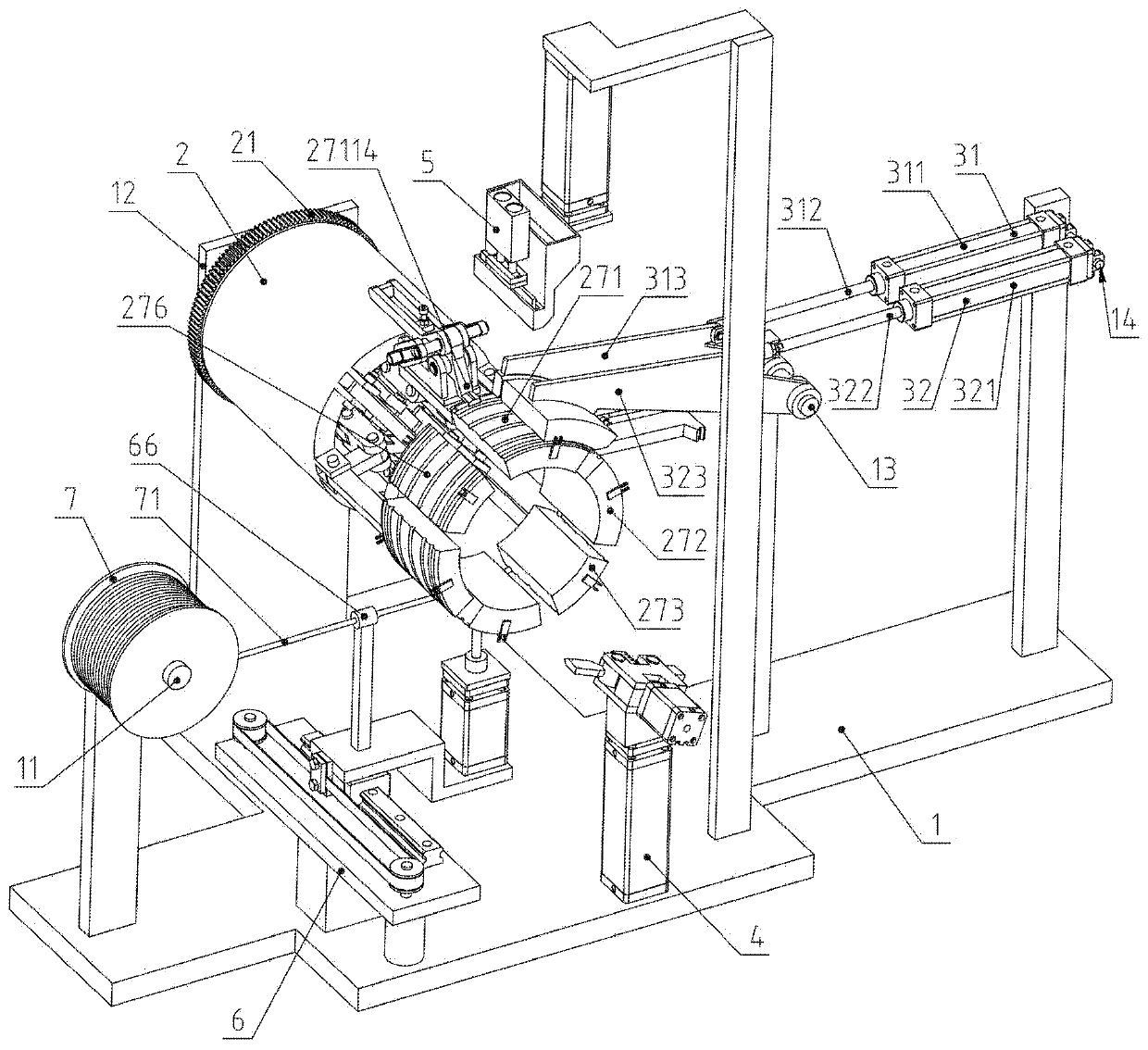

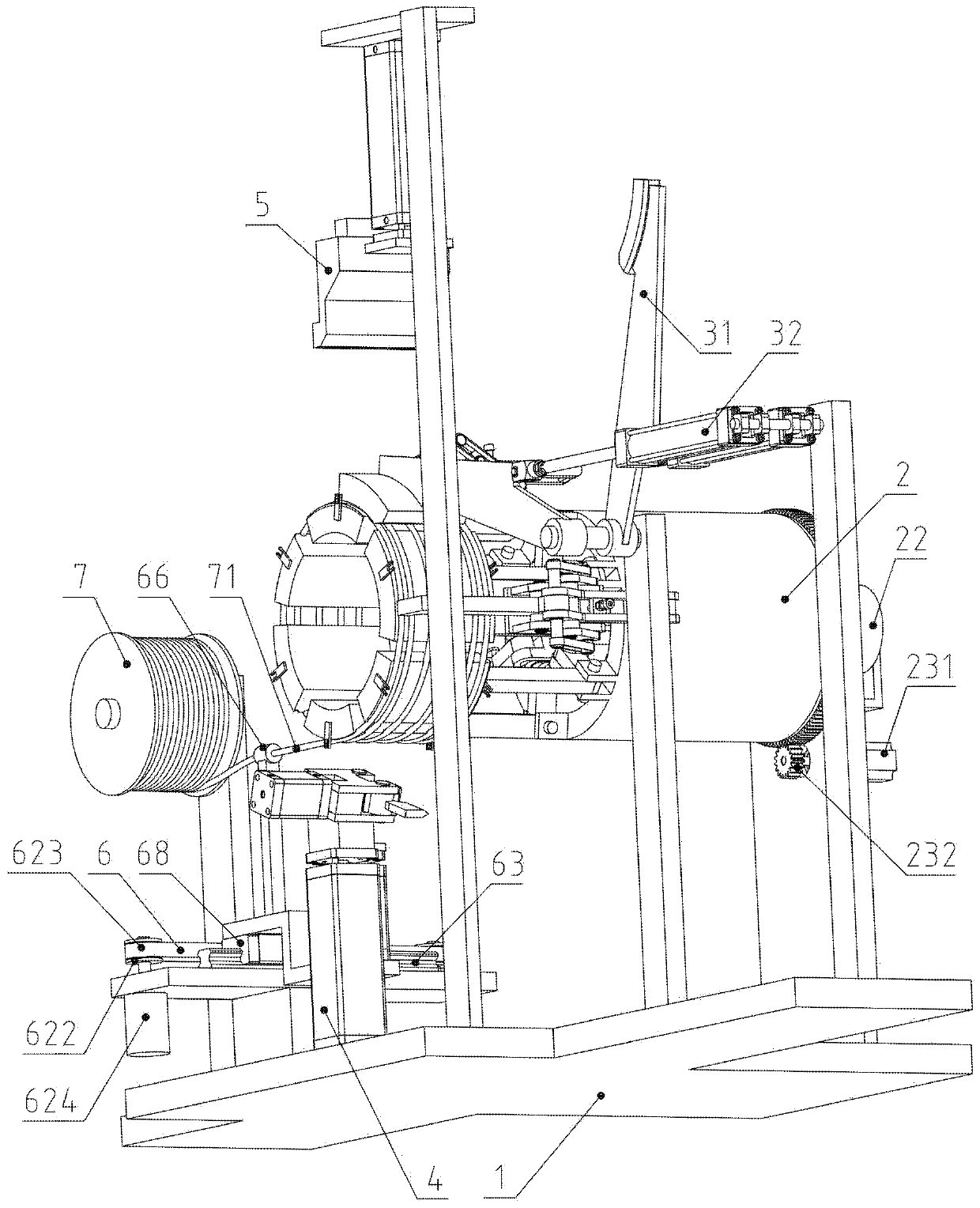

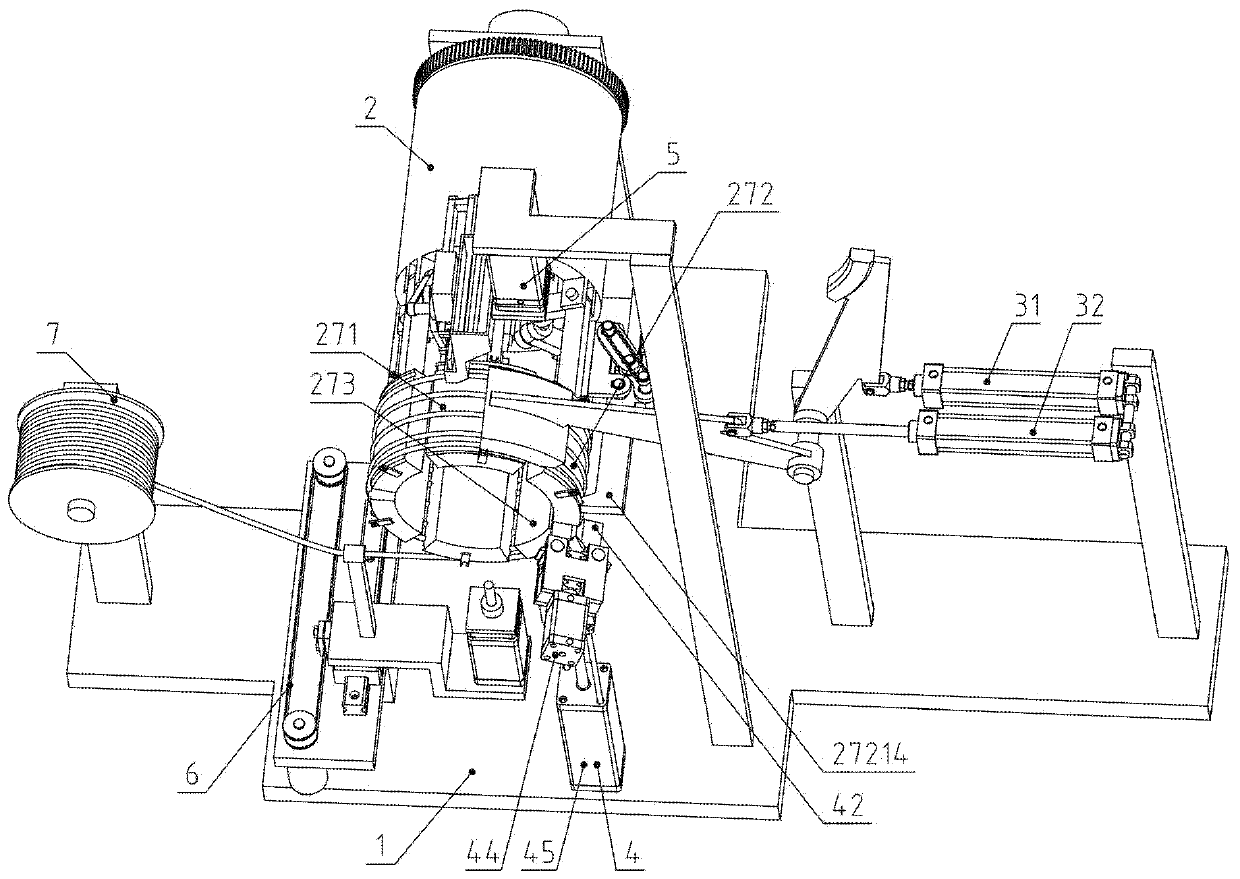

[0031] Example: see Figure 1 to Figure 25 .

[0032]A processing equipment for roller can ear rubber wheel reinforcing hoop, including frame 1, rotating assembly 2, arc pressing assembly 1 31, arc pressing assembly 2 32, shearing assembly 4, axial rib placement assembly 5, guide and spot welding assembly 6 and a welding power supply; the rotary assembly 2 includes a slewing bearing 21, an oil pressure gyrator 22, a rotary servo motor 231, a drive gear 232, a push-pull hydraulic cylinder 4, a push-pull bowl 25, six connecting rods 26, six splits and a rotary drum 28; Slewing bearing 21 is the transmission type described in the fifth edition of "Mechanical Design Handbook" Volume 2, Page 7-481, published by Chemical Industry Press and edited by Cheng Daxian. Support, the slewing ring 21 includes the outer ring 211 of the slewing ring with gear teeth and the inner ring 212 of the slewing ring; the frame 1 is provided with a rotating assembly bracket 12, and the inner ring 212 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com