Truck wheel with reinforcing ribs on mounting face

A technology of reinforcing ribs and mounting surfaces, applied in the direction of wheels, spoked wheels, vehicle parts, etc., can solve the problems of cracking of bolt positioning holes, loose bolts, incomplete fitting, etc., to improve stability and safety, increase The effect of installation tightness and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the implementation methods and accompanying drawings. Here, the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention. Below is the description that the present invention is carried out in conjunction with accompanying drawing:

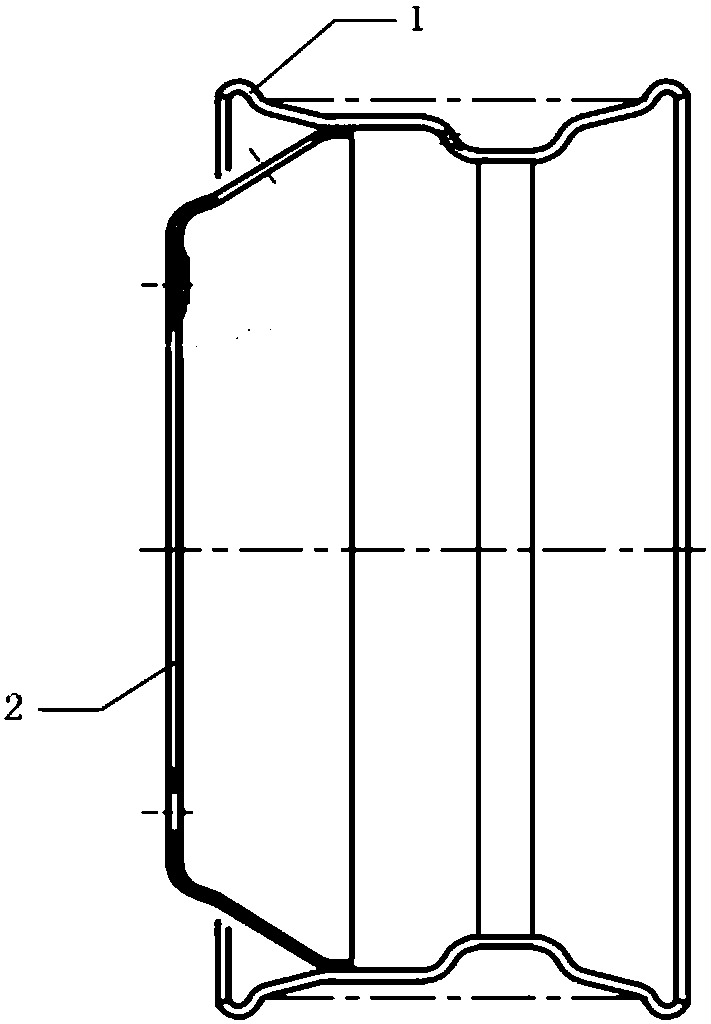

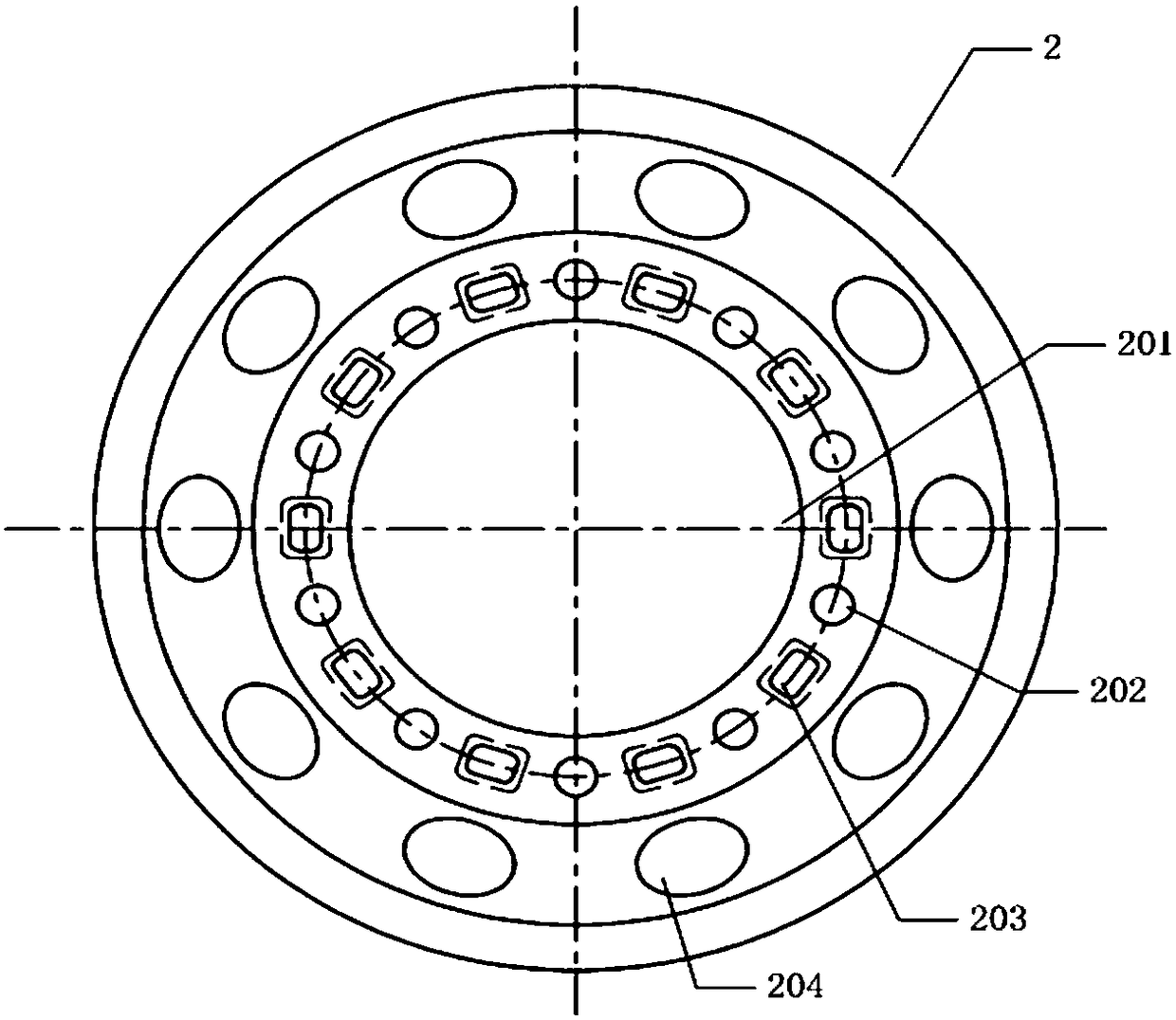

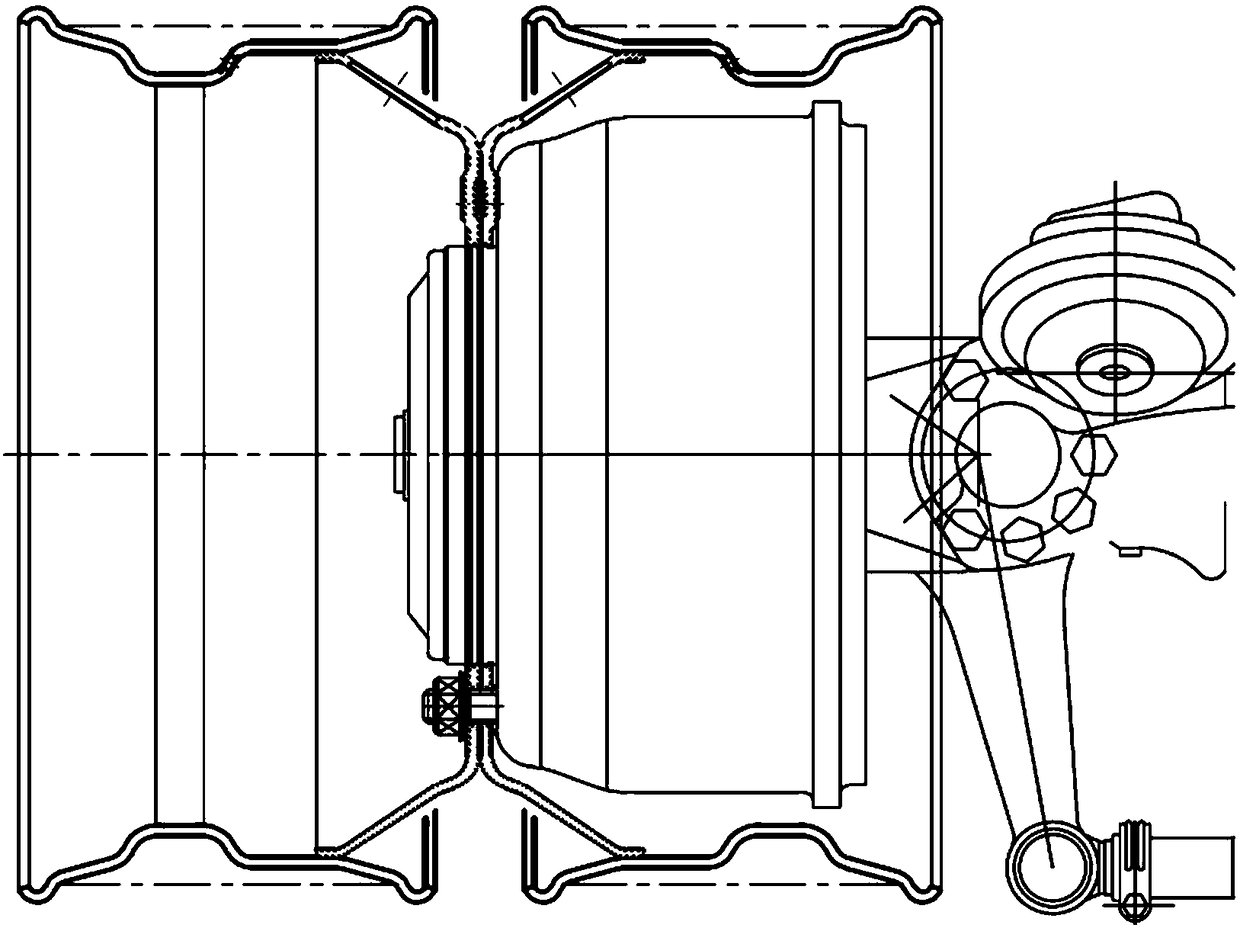

[0019] combined with figure 1 , a truck wheel with reinforcing ribs on the mounting surface, including a rim 1 and a spoke 2. The rim 1 is a part used to install and support the tire on the wheel, and the spoke 2 is a supporting part connected to the axle and the rim 1 at both ends of the wheel respectively. The inner side of the rim 1 and the outer side of the spokes 2 are connected by welding; the outer side of the rim 1 is used to install tires; the other side of the spok...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com