Tower crane anti-swing operation control method

A tower crane, operation control technology, applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of increasing equipment cost, increasing the complexity of the control system, and the control amount cannot directly control the swing of the load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

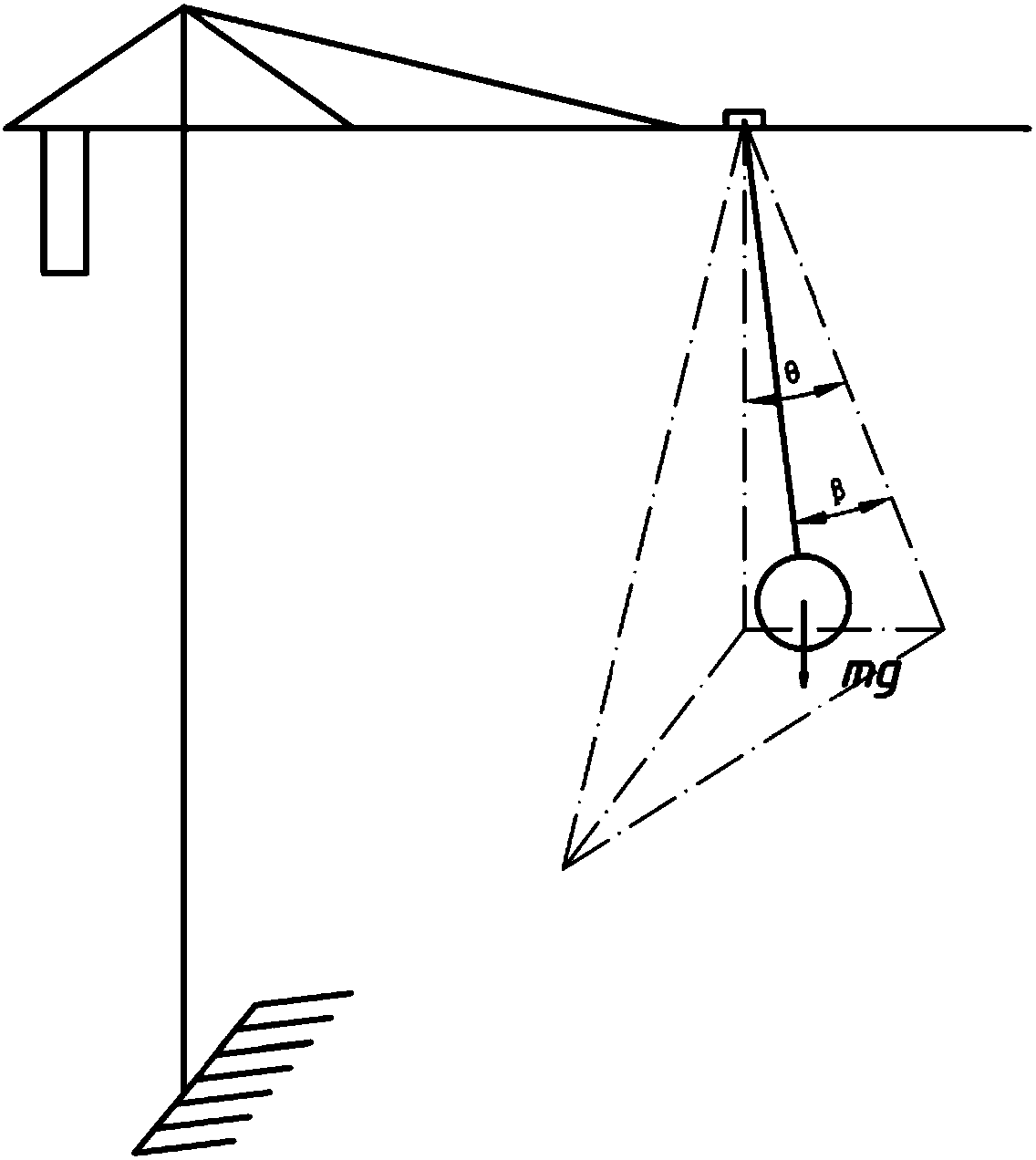

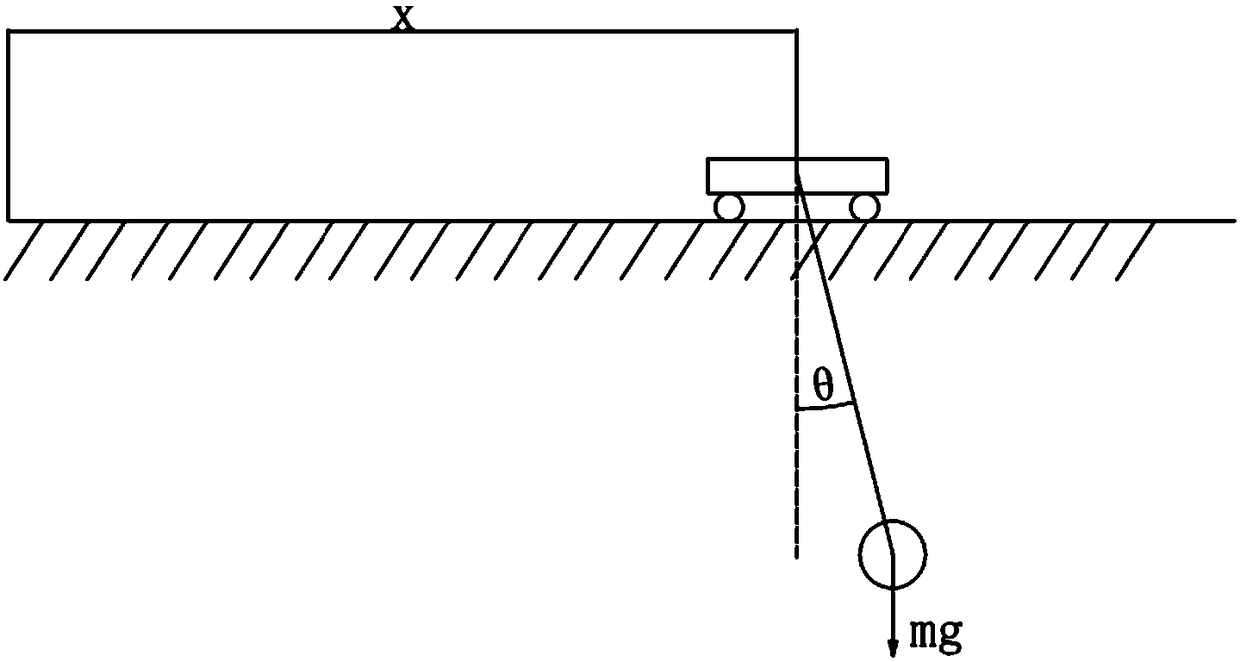

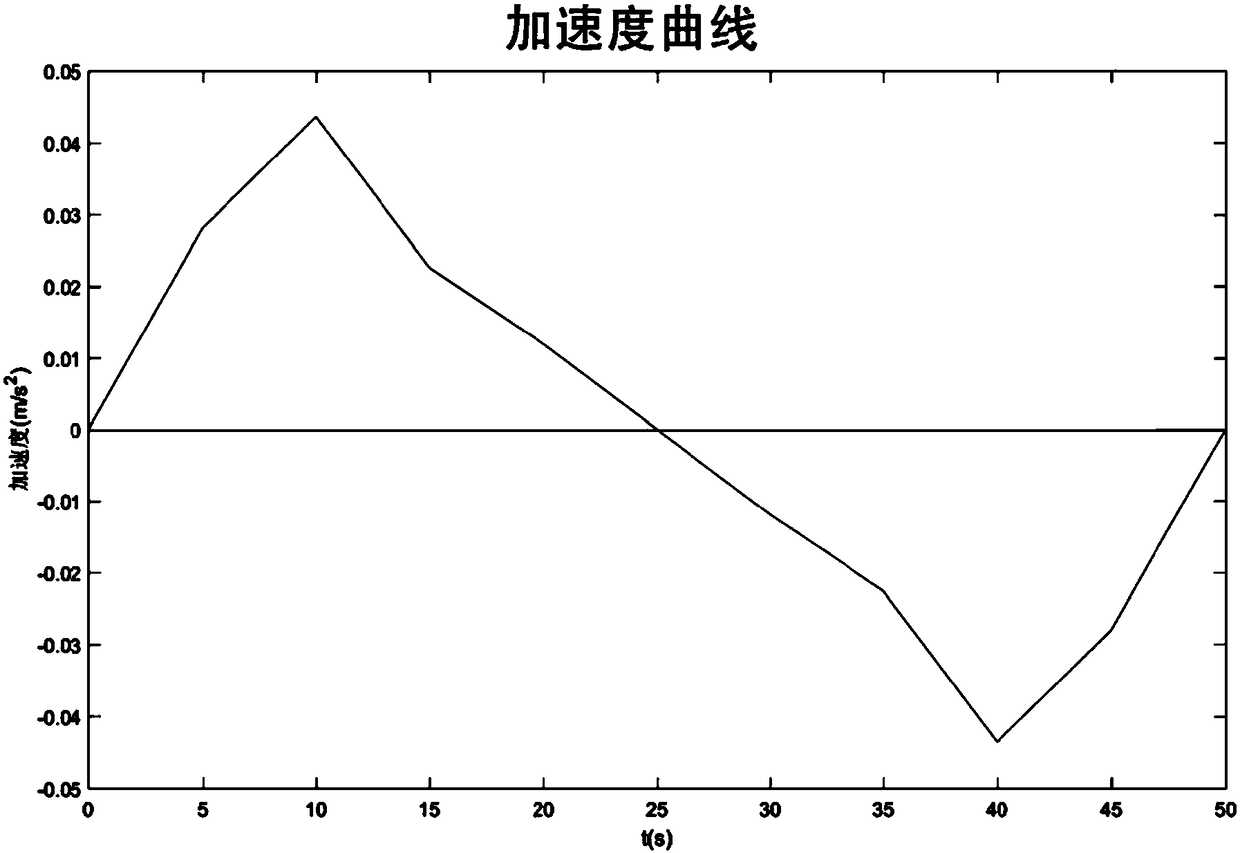

[0056] The present invention provides a tower crane anti-sway planning method, comprising: obtaining the operation parameters of the tower crane, planning the operation control curve of the tower crane according to the operation parameters; using the acceleration curve obtained by planning as the crane operation input to control the luffing mechanism / Acceleration / angular acceleration of the slewing mechanism. The present invention and the provided anti-sway planning method for tower cranes will be described in detail below.

[0057] During the process of transporting the load, the tower crane plans an acceleration curve with anti-sway function according to the input operating parameters, and operates according to the planned acceleration curve, and there is no residual swing after the luffing mechanism reaches the end point.

[0058] Step 1, input of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com