Fire hydrant connecting terminal

A technology for connecting terminals and fire hydrants, used in hose connection devices, pipes/pipe joints/fittings, fire rescue, etc. It can solve problems such as connection errors, harm to life and property, and different installation quality, and meet the needs of connection. , good reliability, convenient connection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

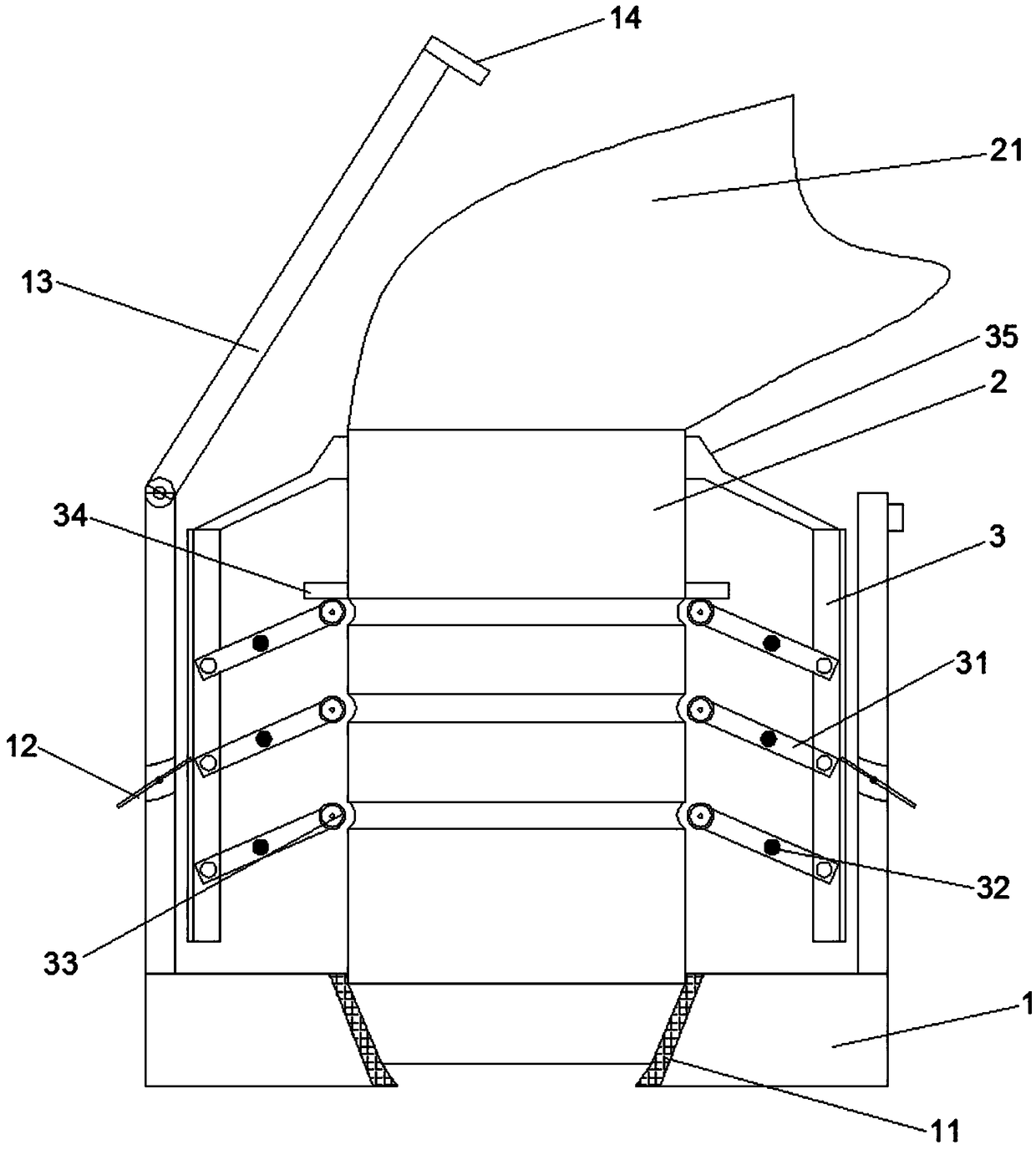

[0018] refer to figure 1 , a connection terminal for a fire hydrant, comprising a fire hydrant connector 1 and a hose connector 2, the hose connector 2 is connected to a hose 21, the bottom of the fire hydrant connector 1 is provided with a water inlet, and the water inlet is connected to the fire hydrant The main body is connected, the water inlet is provided with a sealing ring 11, the shape of the hose joint 2 matches the water inlet, and both sides of the fire hydrant joint are provided with locking mechanisms. A pressing block 34 matching the locking mechanism is provided.

[0019] The locking mechanism includes a guide rod 3 and a plurality of cross bars 31, one end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com