Inspection chamber peripheral backfilling method and application thereof

An inspection well and layered backfilling technology, which is applied to fill, waterway systems, drainage structures, etc., can solve problems such as affecting the comfort and safety of vehicles, settlement of inspection wells, and small backfilling area, so as to reduce the downfall around inspection wells. sink, increase stability and shear resistance, and ensure the effect of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

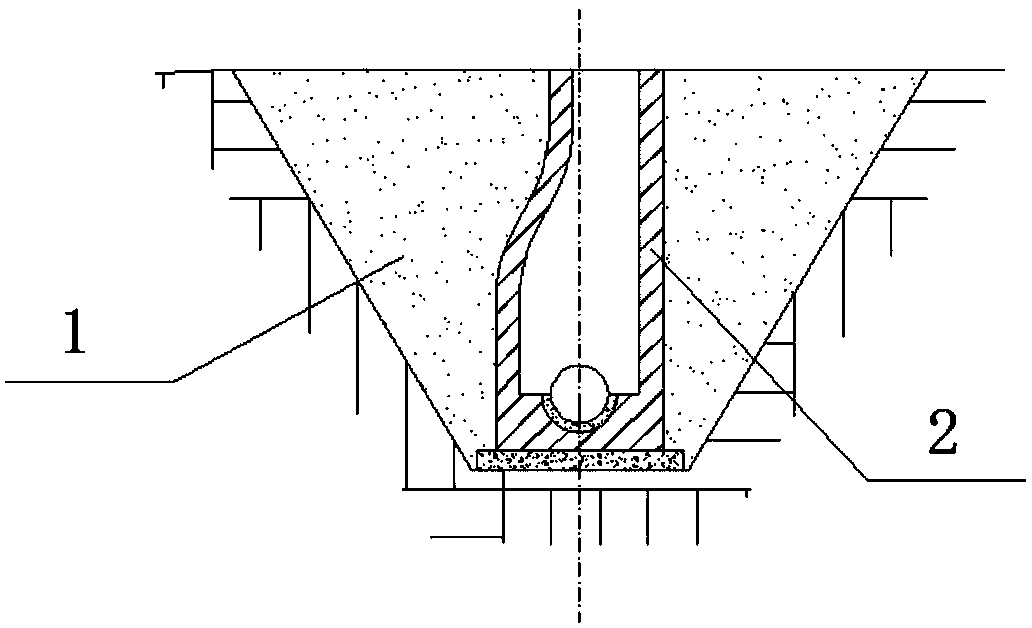

[0075] A method for backfilling around an inspection well, comprising the following steps:

[0076] (1) Inspection well masonry, experiment and acceptance;

[0077] (2) cleaning the base, leveling and compacting;

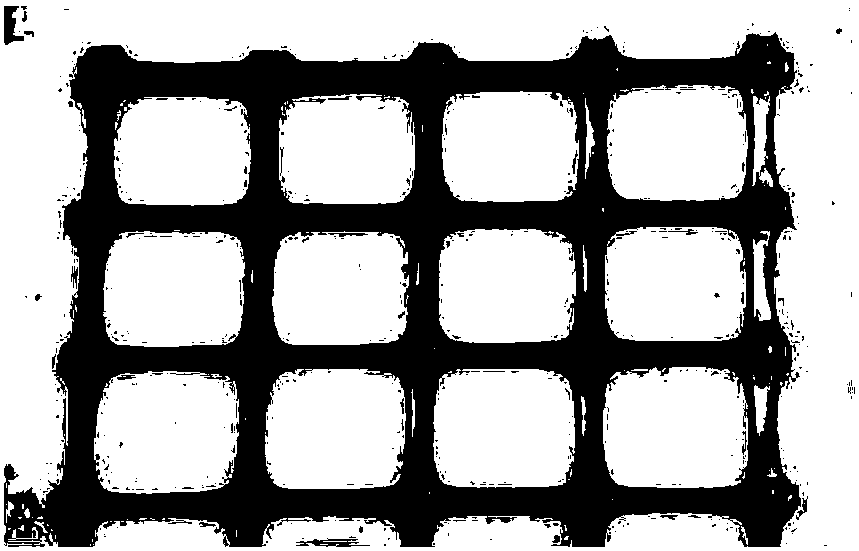

[0078] (3) Set the first geogrid at the bottom around the inspection well, and then use loess, lime soil or natural graded gravel backfill materials for layered backfill compaction. The compaction thickness of each layer of backfill is 20cm. After backfilling 50cm, Set up the second geogrid, and then use loess, lime soil or natural graded gravel backfill materials for layered backfill compaction. The compaction thickness of each layer of backfill is 20cm. After backfilling 50cm, set the third geotechnical Grid, so repeated, until backfilling to the design elevation of 2m.

Embodiment 2

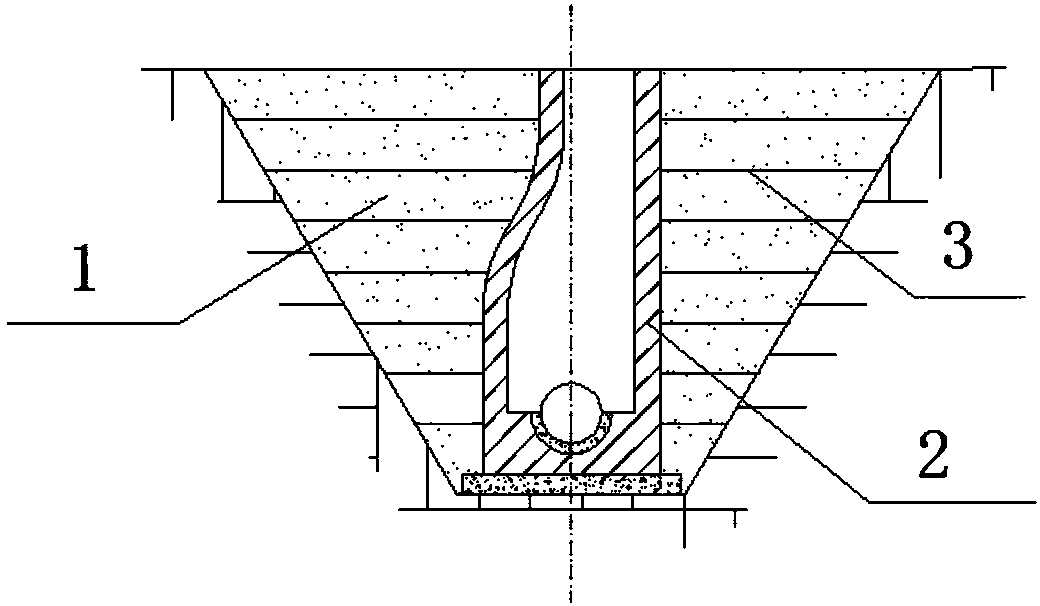

[0080] A method for backfilling around an inspection well, comprising the following steps:

[0081] (1) Inspection well masonry, experiment and acceptance;

[0082] (2) cleaning the base, leveling and compacting;

[0083] (3) Set the first geogrid at the bottom around the inspection well, and then use loess, lime soil or natural graded gravel backfill materials for layered backfill compaction. The compaction thickness of each layer of backfill is 18cm. After backfilling 60cm, Set up the second geogrid, and then use loess, lime soil or natural graded gravel backfill materials for layered backfill compaction. The compaction thickness of each layer of backfill is 18cm. After backfilling 60cm, set the third geotechnical Grid, so repeated, until backfilling to the design elevation of 2.5m.

Embodiment 3

[0085] A method for backfilling around an inspection well, comprising the following steps:

[0086] (1) Inspection well masonry, experiment and acceptance;

[0087] (2) cleaning the base, leveling and compacting;

[0088] (3) Set the first geogrid at the bottom around the inspection well, and then use loess, lime soil or natural graded gravel backfill materials for layered backfill compaction. The compaction thickness of each layer of backfill is 18cm. After backfilling 55cm, Then set up the second geogrid, and then use loess, lime soil or natural graded gravel backfill materials for layered backfill compaction. The compaction thickness of each layer of backfill is 18cm. After backfilling 55cm, set the third geotechnical Grid, so repeated until backfilling to the design elevation of 2.2m.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com