Loess collapsibility evaluation and calculating method

A calculation method and technology for collapsibility, applied in the field of evaluation and calculation of loess collapsibility, can solve problems such as unsuitable general use, large variation of correction coefficient, and complicated test process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

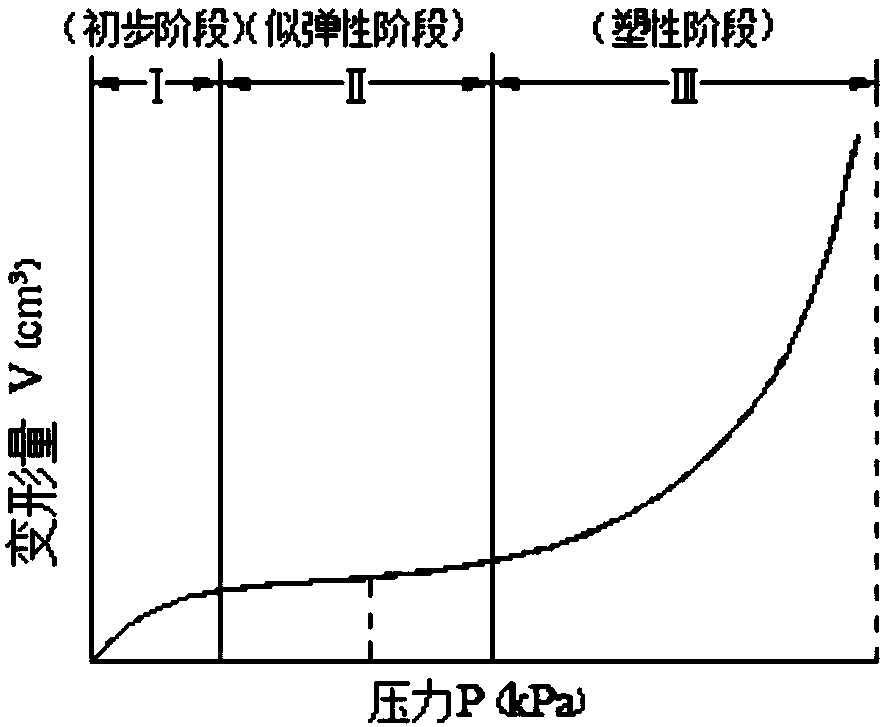

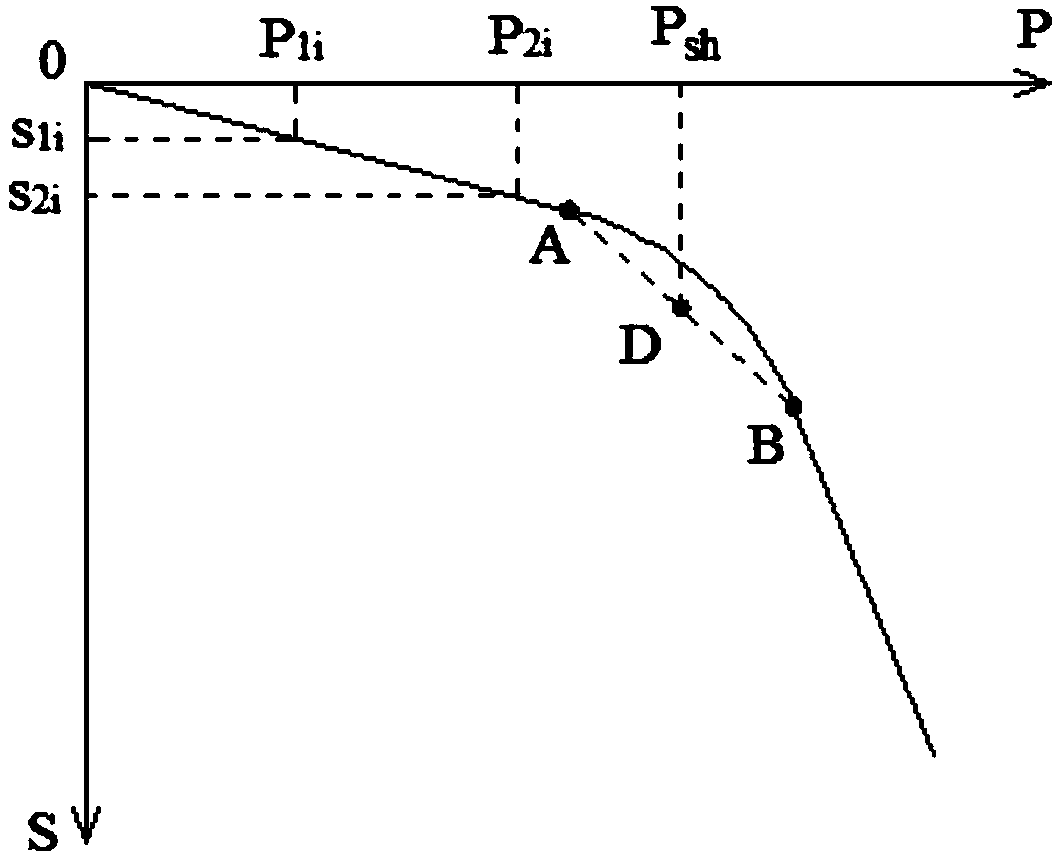

[0035] The invention discloses a method for evaluating the collapsibility of loess through a water injection side pressure test method in a hole. The premise of side pressure test is to have a certain understanding of the collapsibility of the entire (field) site, such as the excavation or drilling of exploratory wells, and the determination of the collapsibility coefficient and self-weight collapsibility coefficient at different depths.

[0036] An evaluation calculation method for loess collapsibility, comprising the following steps:

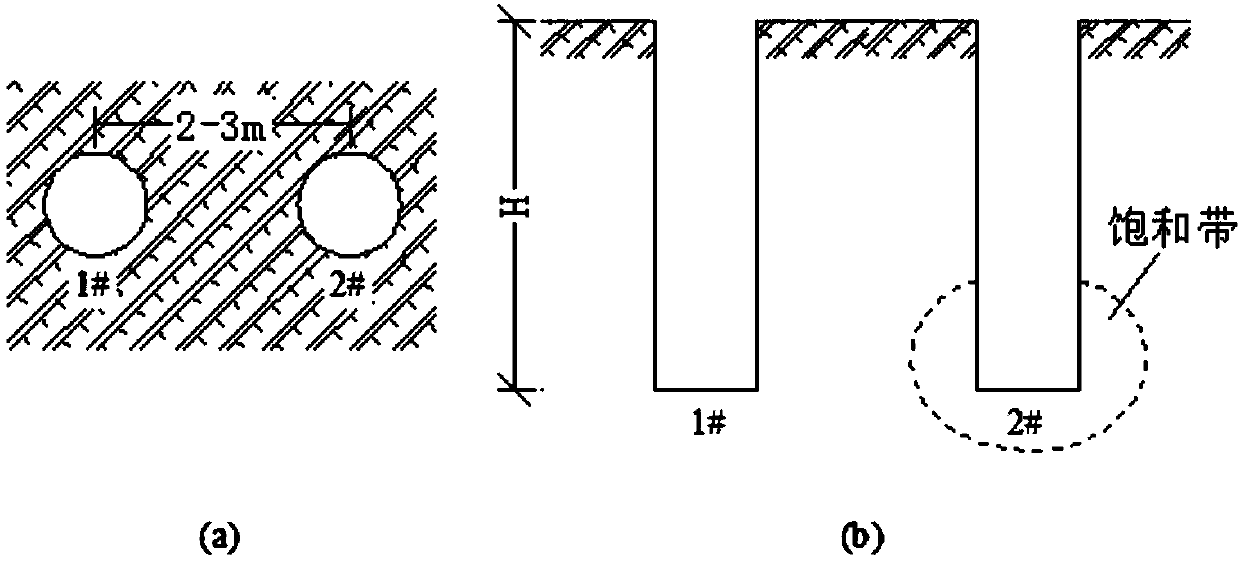

[0037] Step 1, set up the first borehole (1#) and the second borehole (2#) at intervals in the test site, and both boreholes are drilled to the bottom of the collapsible loess layer; in the two boreholes , respectively determine multiple test points from top to bottom;

[0038] In this scheme, the first borehole and the second borehole are set for side pressure tests in natural state and flooded state respectively. The distance between the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com