A Vertical Tube Efficient Falling Film Evaporator

A falling-film evaporator, high-efficiency technology, applied in vertical tube evaporators, evaporator accessories, evaporation, etc., can solve the problems of high requirements for evaporator manufacturing and installation, insufficient heating of liquid, uneven initial distribution, etc. Achieve the effect of low operating cost, uniform liquid volume and high evaporation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

[0025] The multiple mentioned in this implementation refers to two or more.

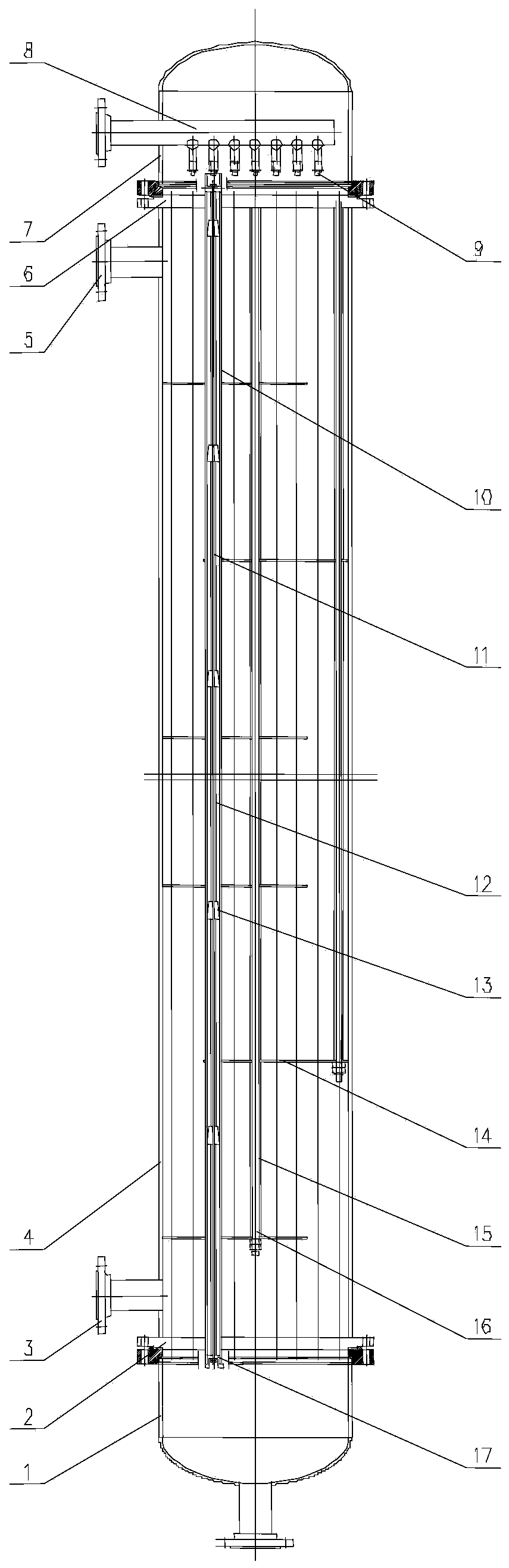

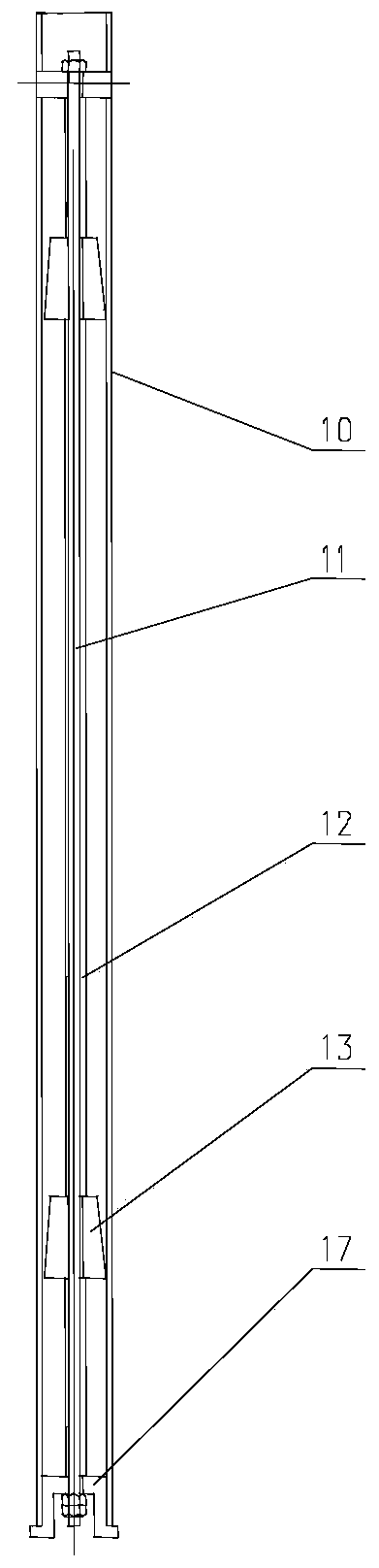

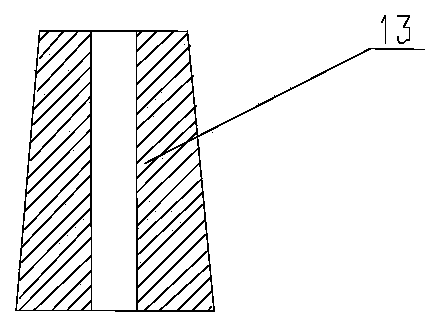

[0026] In the figure, lower tube box 1, lower tube plate 2, condensed water outlet 3, shell 4, steam inlet 5, upper tube plate 6, upper tube box 7, liquid distributor 8, spiral nozzle 9, heat exchange tube 10, Fixed rod 11, positioning pipe 12, vapor-liquid redistribution element 13, support plate 14, spacer pipe 15, pull rod 16, fixing piece 17, liquid inlet main pipe 18, liquid distribution pipe 19, drainage pipe 20, liquid distribution hole 21.

[0027] A vertical tube high-efficiency falling film evaporator, comprising an upper tube box 7, a shell 4, a lower tube box 1, a liquid distributor 8 and a plurality of heat exchange tubes 10, the upper end and the lower end of the shell are respectively connected to the upper The tube box 7 is airtightly connected with the lower tube b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com