Production device for multi-roll solid-pin electrode nanofiber non-woven fabrics

A production device and non-woven fabric technology, which is applied in the fields of non-woven fabrics, fiber treatment, textiles and papermaking, etc., can solve the problems of drop spinning voltage, thick fiber diameter, clogging, etc., and achieve uniform liquid loading and reduce to Effect of spinning voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

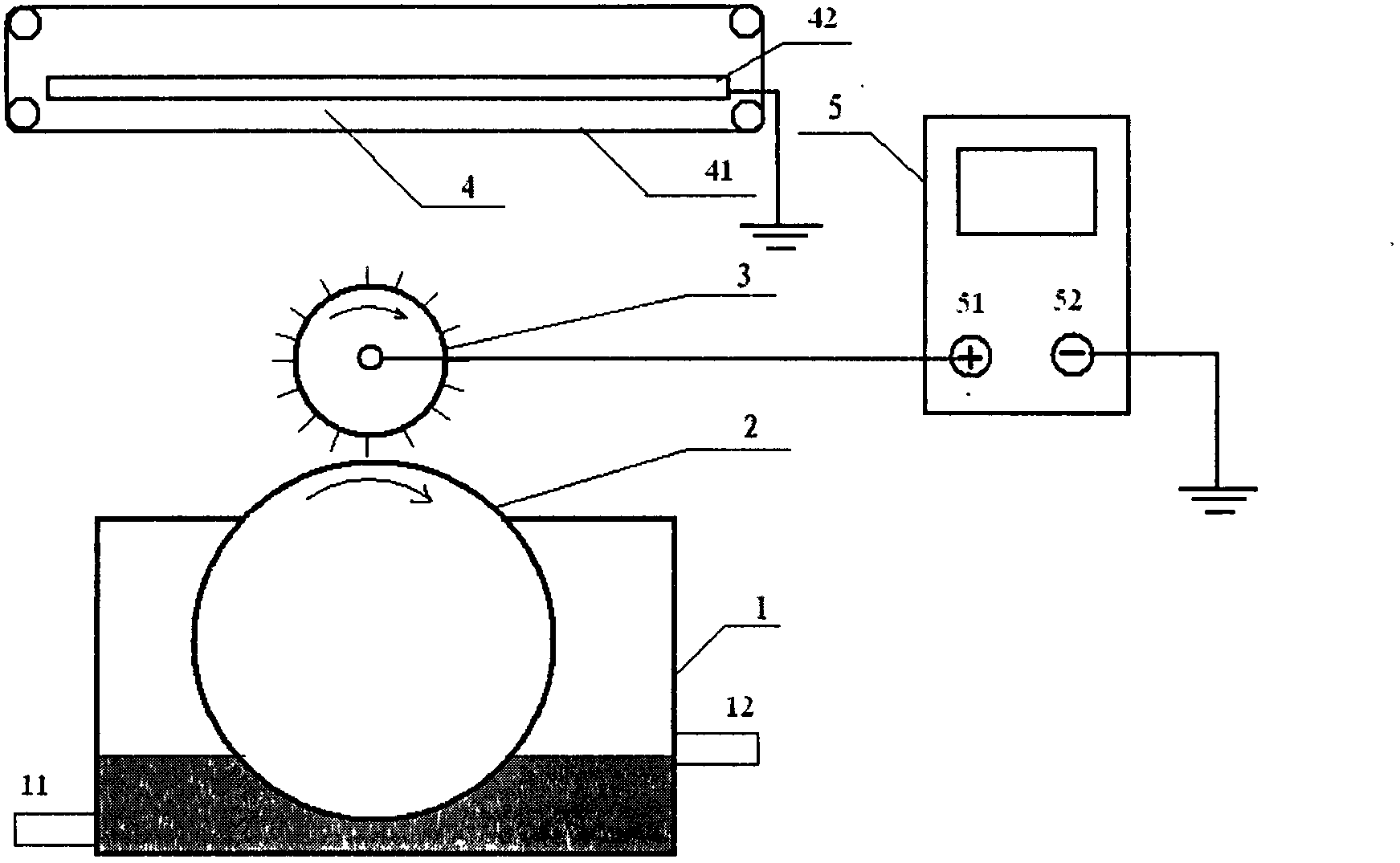

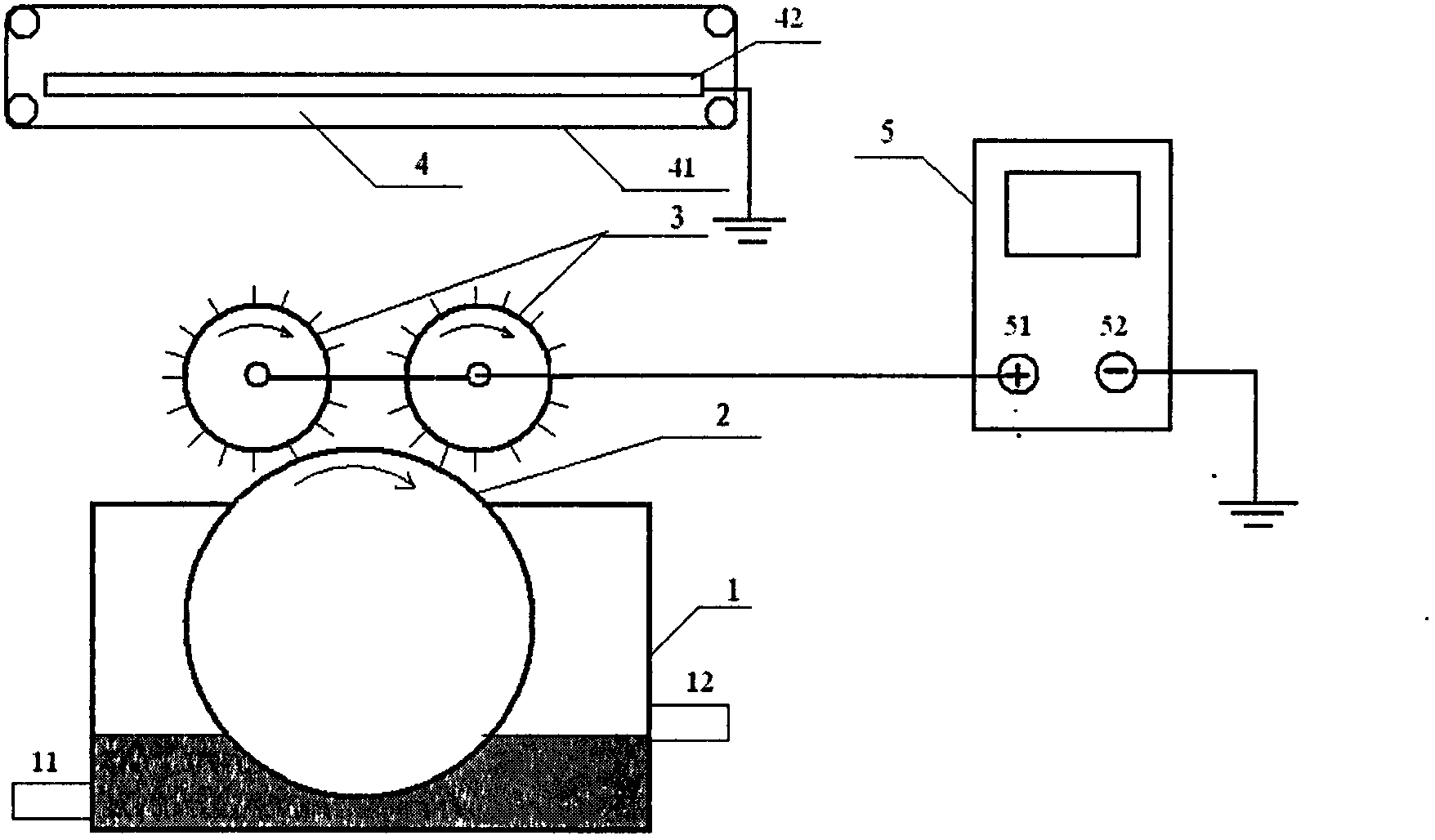

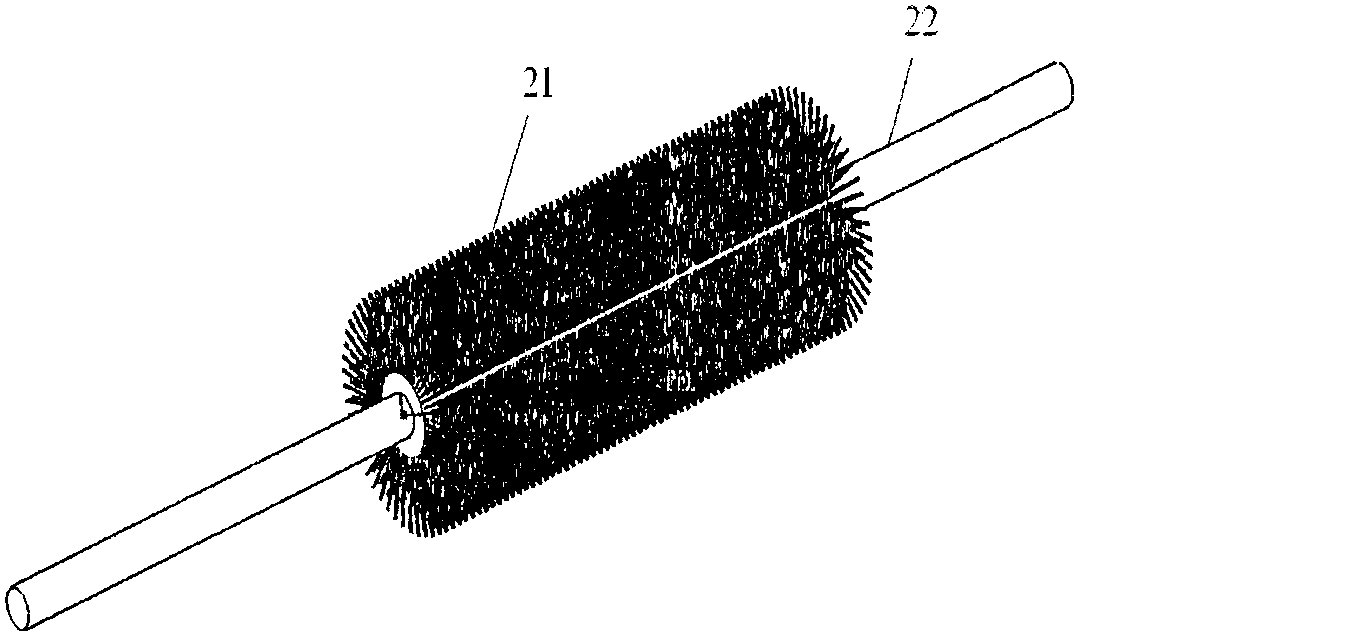

[0034] Such as figure 1 A double-roller solid needle electrode nanofiber production device shown includes a liquid storage tank 1, a liquid transfer roller 2, a solid needle electrode spinneret roller 3, a receiving device 4, and a high-voltage electrostatic generator 5. The width of the liquid transfer roller 2 is 20cm, and the radius is 5cm, and the radius of the solid needle electrode spinneret roller 3 (the distance from the center of the axis of the solid needle tip) is 5cm, and the selection is as follows: Figure 4 For the fork-shaped solid needle electrode shown, the length of 32 solid needle electrodes is 1cm, the width of the fork is 0.5mm, and the needle density is 6 needles / cm 2 , the distance between the needle tip and the surface of the fluorine rubber roller 3 with liquid is 0.5mm. During work, 30% polyvinyl alcohol / water spinning solution is injected into the liquid storage tank 1 through the liquid inlet 11, and the excess spinning solution flows out through ...

Embodiment 2

[0036] Such as figure 1 A double-roller solid needle electrode nanofiber production device shown includes a liquid storage tank 1, a liquid transfer roller 2, a solid needle electrode spinneret roller 3, a receiving device 4, and a high-voltage electrostatic generator 5. The width of the liquid transfer roller 2 is 200cm, and the radius is 50cm, and the radius of the solid needle electrode spinneret roller 3 (the distance from the center of the axis of the solid needle tip) is 20cm, and the selection is as follows: Figure 5 For the cylindrical solid needle electrode shown, the solid needle electrode has 32 needles, the length is 4cm, and the needle density is 16 needles / cm 2 , the distance between the tip of the needle and the surface of the fluorine rubber of the transfer roller 3 is 1 mm. During work, 6% polyvinylpyrrolidone / ethanol spinning solution is injected into the liquid storage tank 1 through the liquid inlet 11, the excess spinning solution flows out through the o...

Embodiment 3

[0038] Such as figure 1 A double-roller solid needle electrode nanofiber production device shown includes a liquid storage tank 1, a liquid transfer roller 2, a solid needle electrode spinneret roller 3, a receiving device 4, and a high-voltage electrostatic generator 5. The width of the liquid transfer roller 2 is 100cm, and the radius is 20cm, and the radius of the solid needle electrode spinneret roller 3 (the distance from the center of the axis of the solid needle tip) is 10cm, and the selection is as follows: Figure 6 For the conical solid needle electrode shown, the solid needle electrode has 32 needles, the length is 2cm, and the needle density is 16 needles / cm 2 , the distance between the tip of the needle and the surface of the fluorine rubber of the transfer roller 2 is 0.5mm. During work, 25% polyurethane / N,N-dimethylformamide spinning solution is injected into the liquid storage tank 1 through the liquid inlet 11, and the excess spinning solution flows out throu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com