General assembly tool for M vehicle body of tram and process thereof

A technology for trams and general assembly tooling, applied in auxiliary devices, manufacturing tools, metal processing equipment, etc., can solve the problems of component assembly deviation, no positioning and clamping, and positioning and clamping are not in place, so as to prevent thermal deformation and assembly. high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

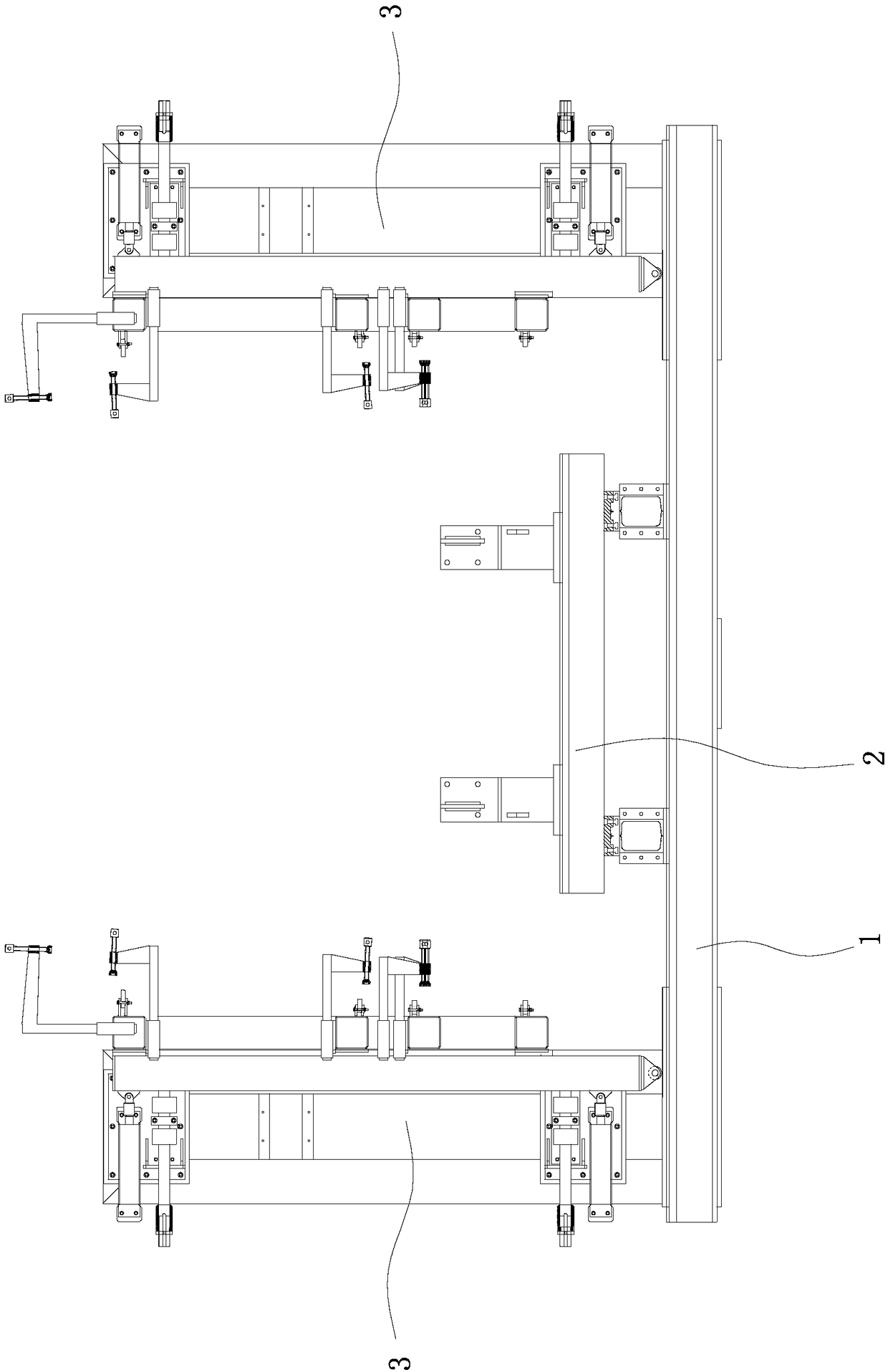

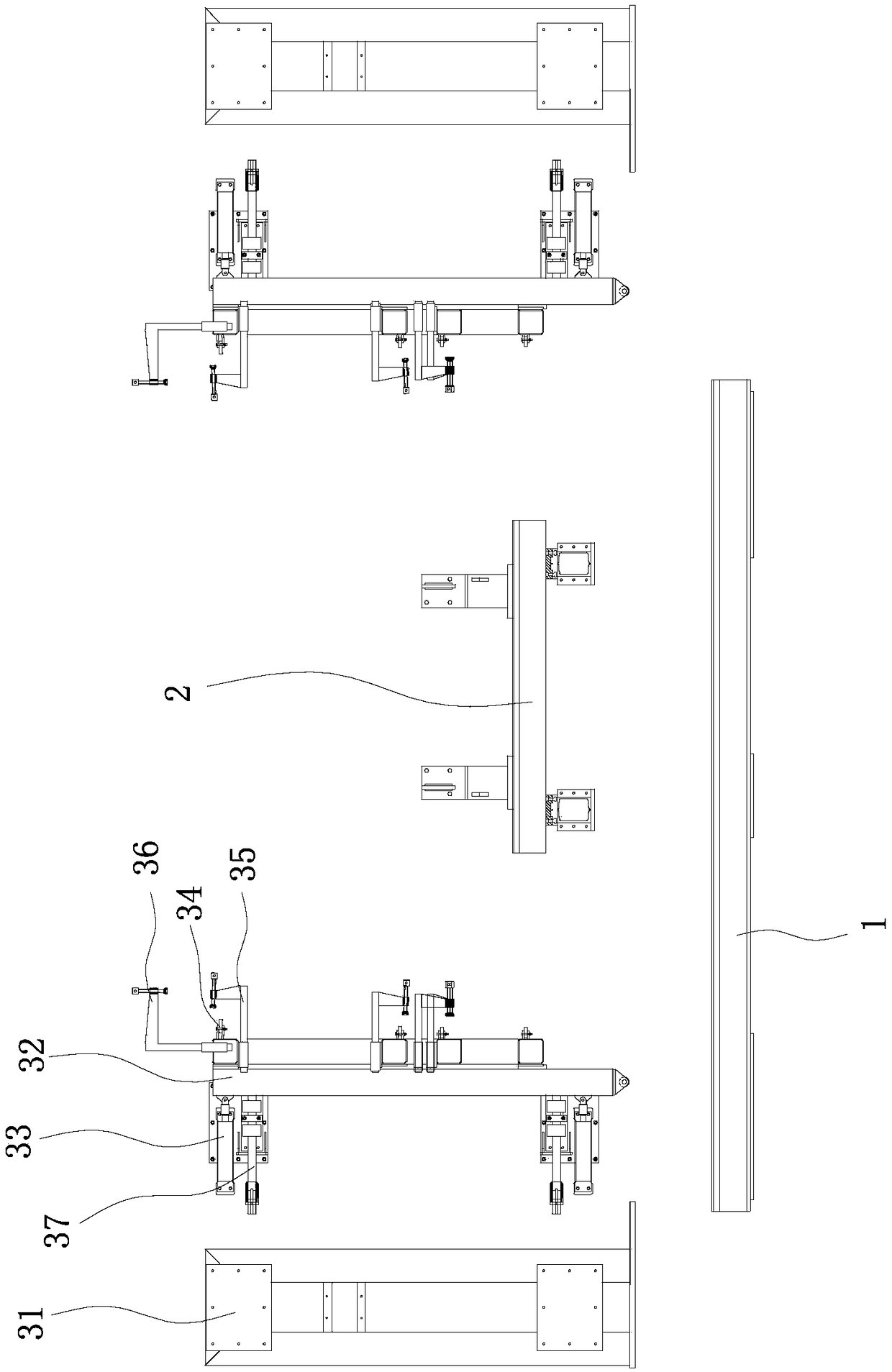

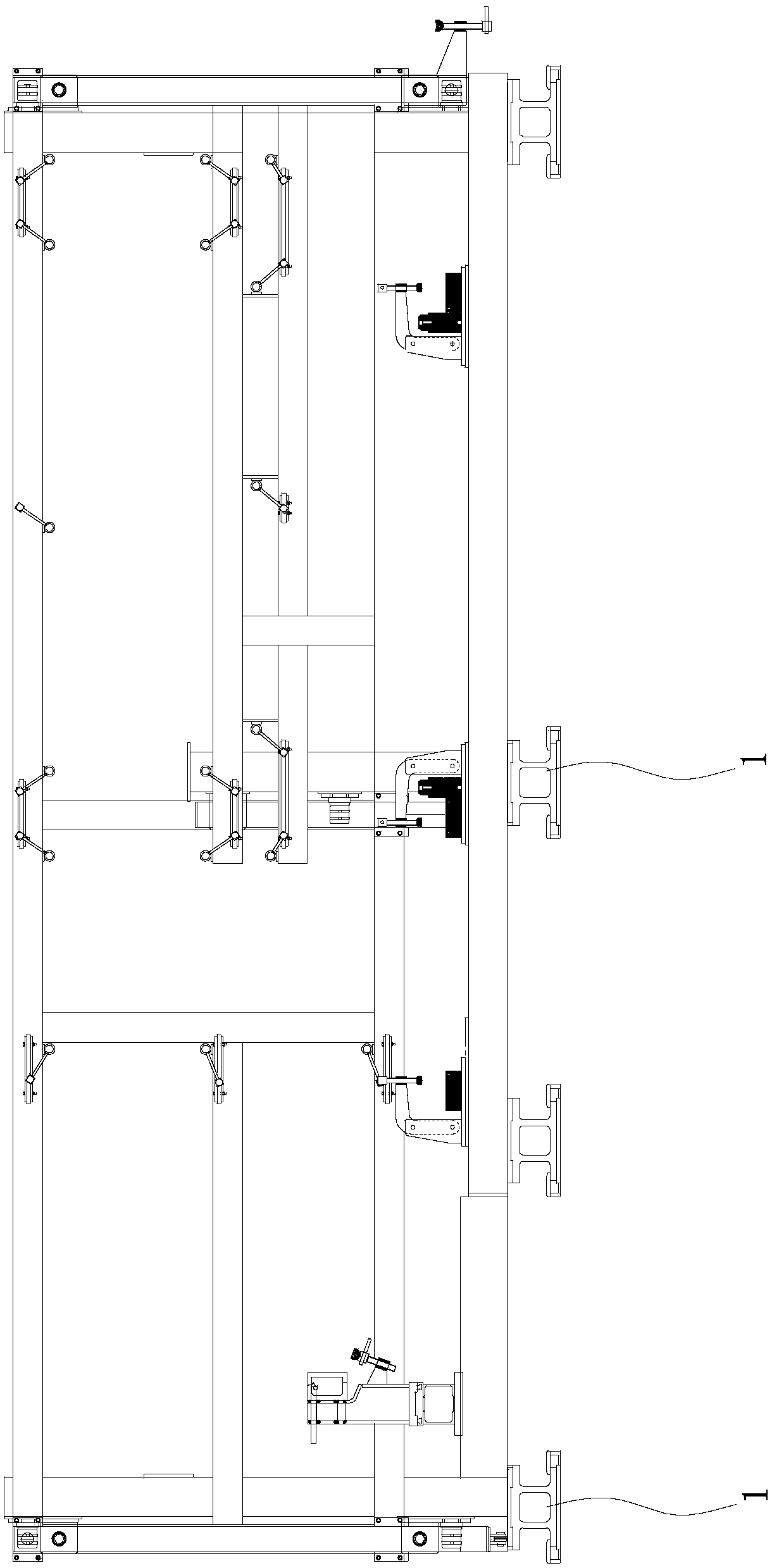

[0038] Such as Figure 1 to Figure 3 Shown, a kind of railcar M car body assembly tooling, comprises bottom beam 1, the first tooling assembly 2 that sets bottom beam 1 middle part and the second tooling assembly 3 that sets bottom beam 1 two ends; The first tooling assembly 2 is used for The underframe and the front end frame of the clamping vehicle body, the second tooling assembly 3 is used for clamping the side wall and the ceiling of the vehicle body; the second tooling assembly 3 includes a column frame 31 connected with the bottom beam 1 and can To the movable frame 32 of sliding.

[0039] Such as image 3 and Figure 5 As shown, the bottom beam 1 includes at least two parallel ones, the bottom beam 1 is provided with a first chute 11 along its axial direction; the first tooling assembly 2 and the column frame 31 are conn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power level | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap