Novel profile cutting device for tempered film

A tempered film and shape technology, applied in glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., can solve problems such as low efficiency, complex structure, cumbersome process, etc., and achieve high efficiency, high safety, and close contact and transmission relationship Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

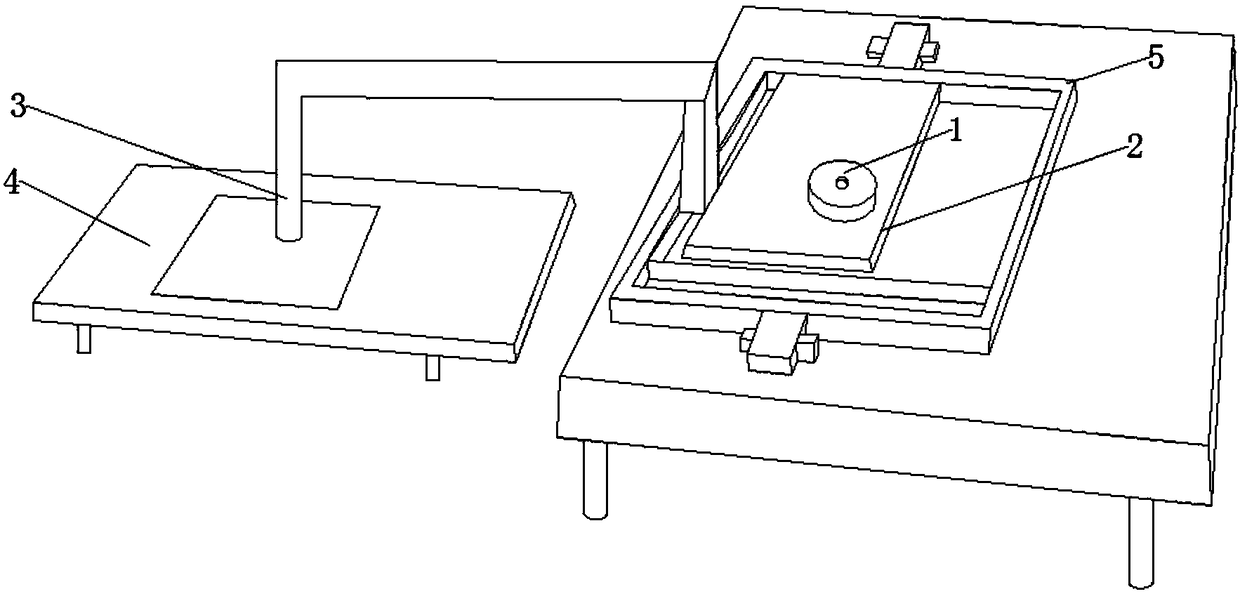

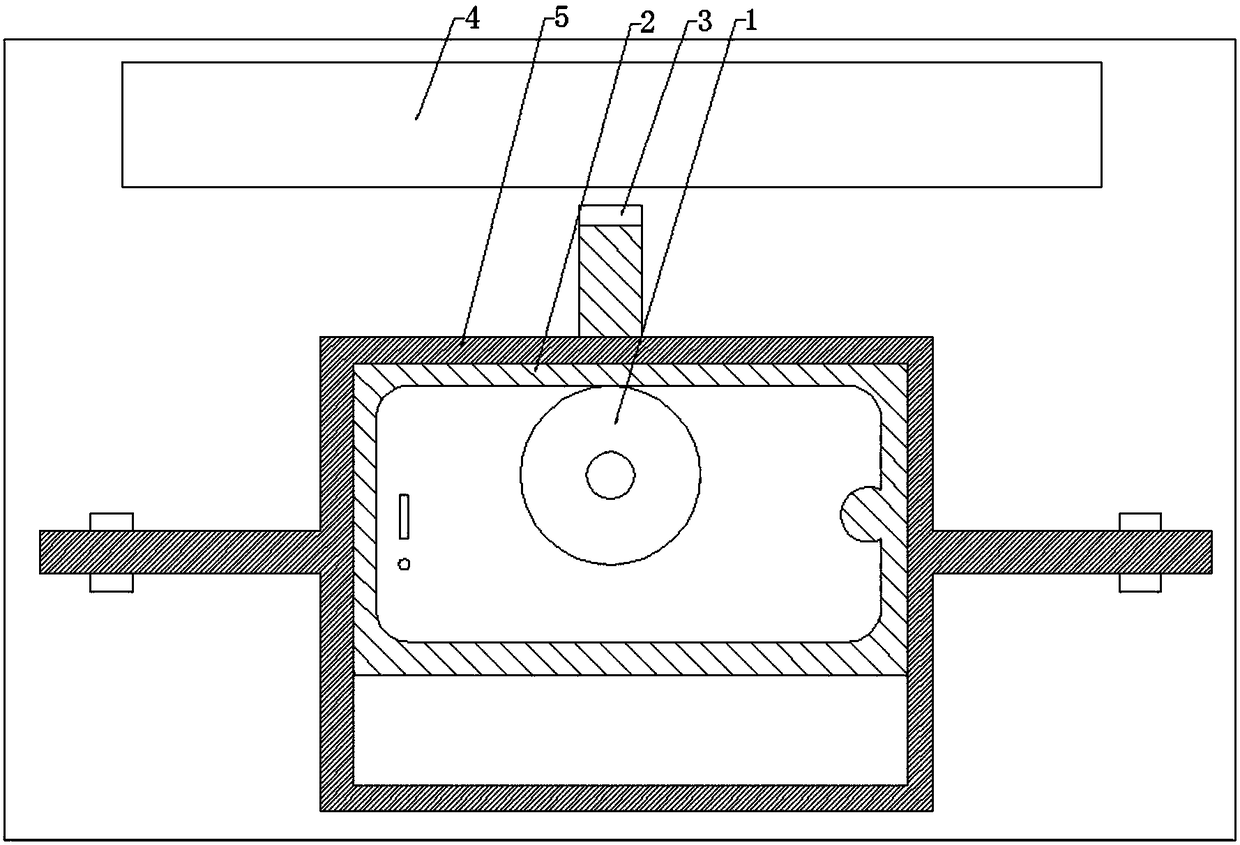

[0030] A new type of tempered film shape cutting device, including a workbench, one side of the workbench is provided with a tempered film fixing table, when the tempered film needs to be cut, the tempered film is placed on the tempered film fixing table; working There is a sliding block on the table, and a cavity is opened inside the sliding block. The shape of the inner wall of the cavity is adapted to the shape of the required toughened film. The inner wall of the cavity is also contacted with a driving wheel, which can drive The sliding block as a whole moves along a certain track; the side of the sliding block close to the tempered film fixing table is connected with a cutting knife through a connecting rod, and the cutting knife can move along the same track as the sliding block to cut the tempered film.

[0031] During the working process, the driving wheel is started, and the driving wheel drives the sliding block and the cutting knife to move along a certain track to c...

Embodiment 2

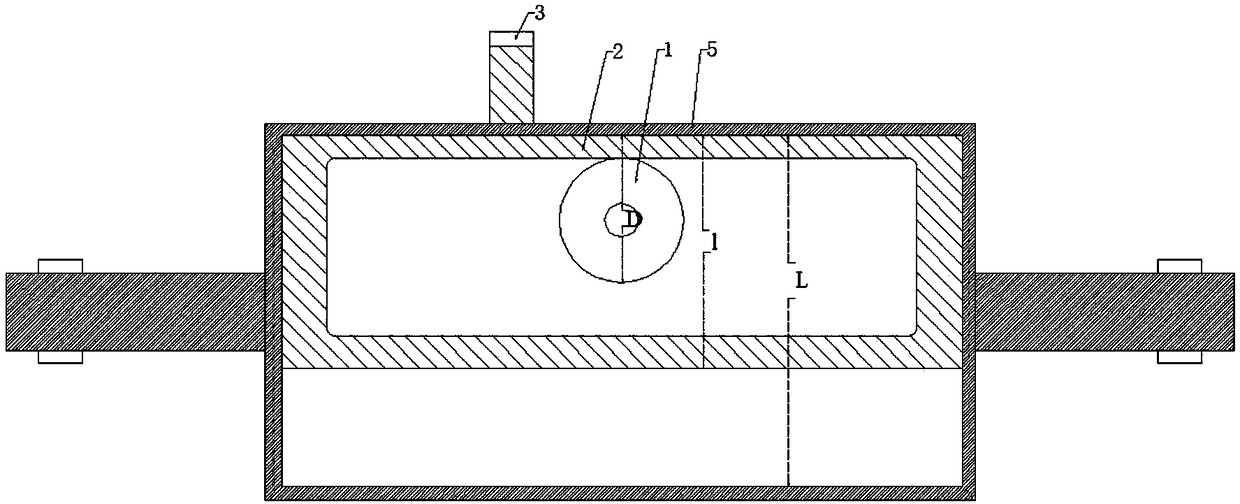

[0033] On the basis of Example 1, the workbench is provided with an outer frame that can move along the length direction of the tempered film fixed table, the sliding block is sleeved in the inner cavity of the outer frame, and the outer frame is fixed in the length direction of the outer frame by two block fixed. Such setting can make the contact and transmission relationship between the sliding block and the driving wheel closer, and enhance the stability and working efficiency of the whole device during operation.

Embodiment 3

[0035] On the basis of Example 2, the width L of the inner cavity of the outer frame is greater than the sum of the width l of the outside of the sliding block and the outer diameter D of the driving wheel, that is, L≥l+D, so that the outer frame will not go to the tempered film The direction of the fixed table is close, which makes the overall safety higher.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com