Reusable back wall for pipeline water pressure test

A hydraulic test and water test technology, which is applied to walls, building components, buildings, etc., can solve the problems of high cost, long construction period, and huge back wall, so as to avoid waste, stabilize the wall, and reduce engineering costs. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

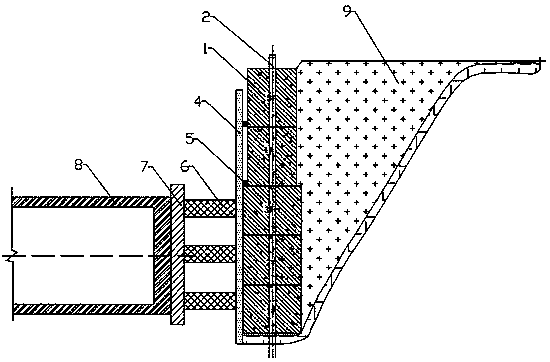

[0025] refer to Figure 1~2 , a reusable back wall for pipeline hydrostatic testing, including a plurality of prefabricated reinforced concrete stacking blocks 1 stacked and arranged, and each of the prefabricated reinforced concrete stacking blocks 1 is inserted into one body through a plurality of steel rods 2 in series Thus forming the back wall. Each corner of each prefabricated reinforced concrete stacking beam block 1 is preferably provided with steel corner guards for protection, so as to avoid damage caused by bumps during transportation. The front side of the prefabricated reinforced concrete stacked beam block 1 is provided with a plurality of back beams 4, the back beams 4 are used to support the support rods 6, and the back beams 4 disperse the support force of the support rods 6 to the prefabricated steel bars The entire surface of the concrete stacking beam block 1 prevents the support rod 6 from directly acting on a single prefabricated reinforced concrete stac...

Embodiment 2

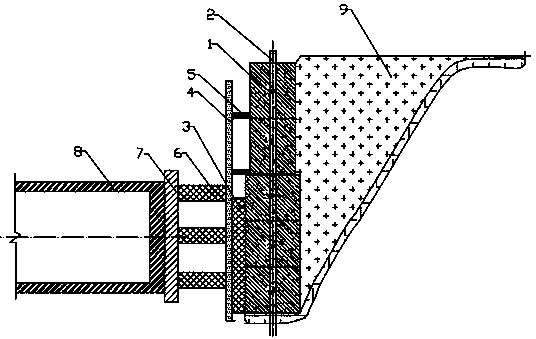

[0031] refer to image 3 and Figure 4 , the difference between this embodiment and the embodiment is:

[0032] A steel plate pad 3 is provided between the back beam 4 and the prefabricated reinforced concrete stacked beam block 1, and the steel plate pad 3 is added to better disperse the pressure from the support rod 6 to the rear of the entire reinforced concrete stacked beam block 1. The back wall, so that the back wall is not easy to overturn and more stable.

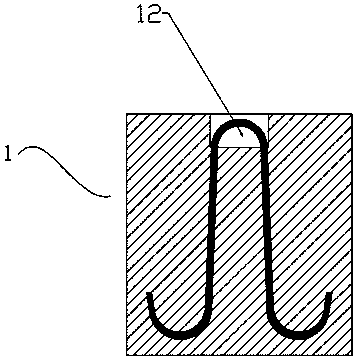

[0033] refer to image 3 , the prefabricated reinforced concrete stacking block 1 is provided with sockets 11 in both the height direction and the width direction, and the size of the prefabricated reinforced concrete stacking block 1 in the height direction is smaller than the size in the width direction; the lower layer The prefabricated reinforced concrete stacking blocks 1 are vertically stacked along the height direction, and the upper prefabricated reinforced concrete stacking blocks 1 are vertically stacke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com