Method for heating and regenerating a particulate filter in the exhaust gas of a gasoline engine

A particle filter, gasoline engine technology, applied to machines/engines, mechanical equipment, exhaust devices, etc., can solve problems such as insufficient accuracy and unsatisfactory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

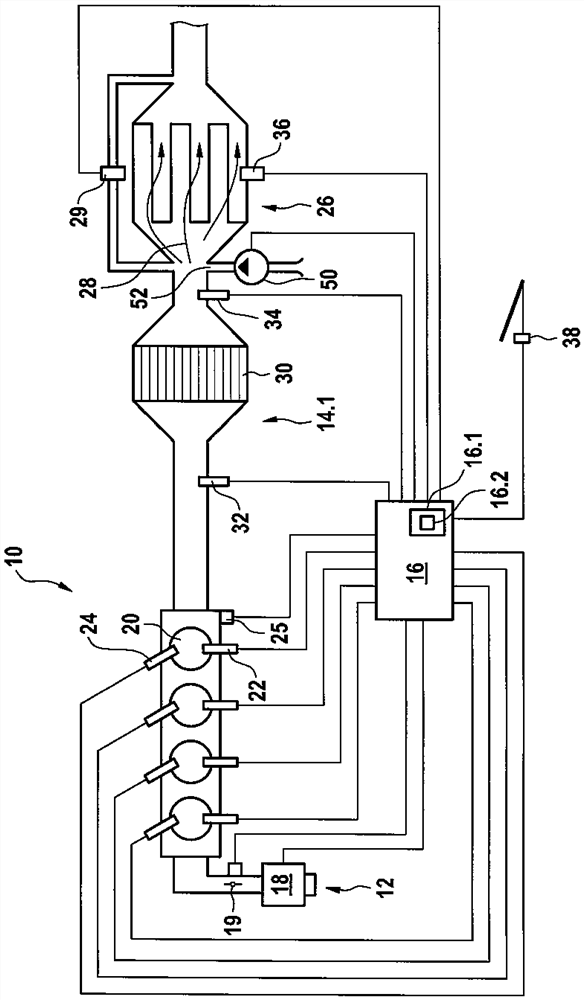

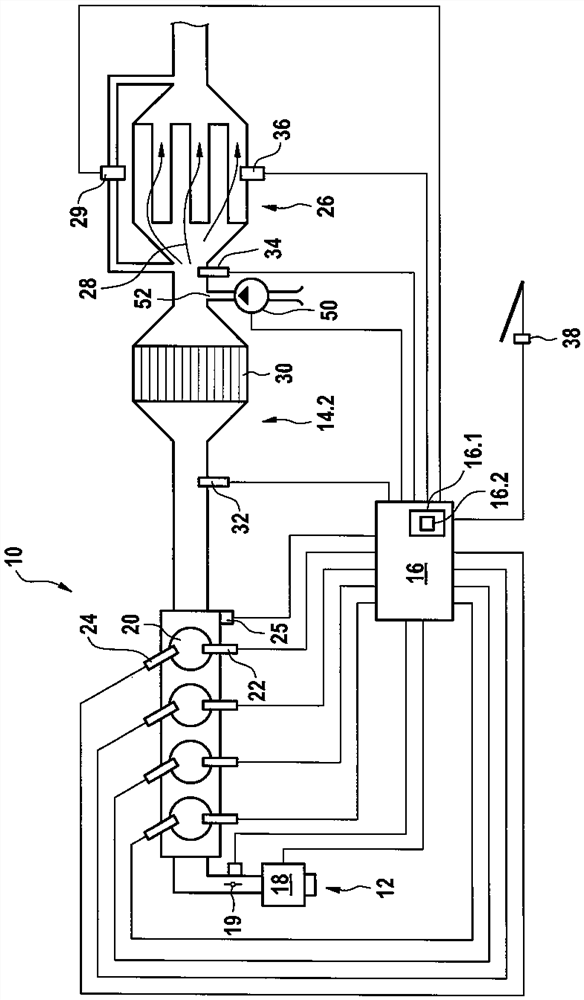

[0027] figure 1Otto engine 10 with air introduction system 12 , first exhaust system 14 . 1 and controller 16 is shown in detail. In the air introduction system 12, an air mass meter 18 and a throttle valve 19 arranged downstream of the air mass meter 18 are arranged. The air flowing into the gasoline engine 10 through the air introduction system 12 is mixed with gasoline in the combustion chamber 20 of the gasoline engine 10, and the gasoline is directly injected into the combustion chamber 20 through the injection valve 20 or in the combustion chamber 20. Injection before the intake valve of the chamber. The resulting combustion chamber filling is ignited and combusted by means of an ignition device 24 , for example a spark plug. Angle of rotation sensor 25 detects the angle of rotation of the shaft of internal combustion engine 10 and thus allows controller 16 to trigger the ignition in a predetermined angular position of the shaft. A driver desire sensor 38 detects the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com