Linear wall washer waterproof adhesive strip automatic packaging system

A waterproof adhesive strip and packaging system technology, which is applied in the direction of air-proof/waterproof devices, lighting devices, lighting device components, etc., can solve the problems that the efficiency cannot be further improved, the product performance cannot be guaranteed, and the application is limited Unstable quality factors, avoiding low production capacity, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

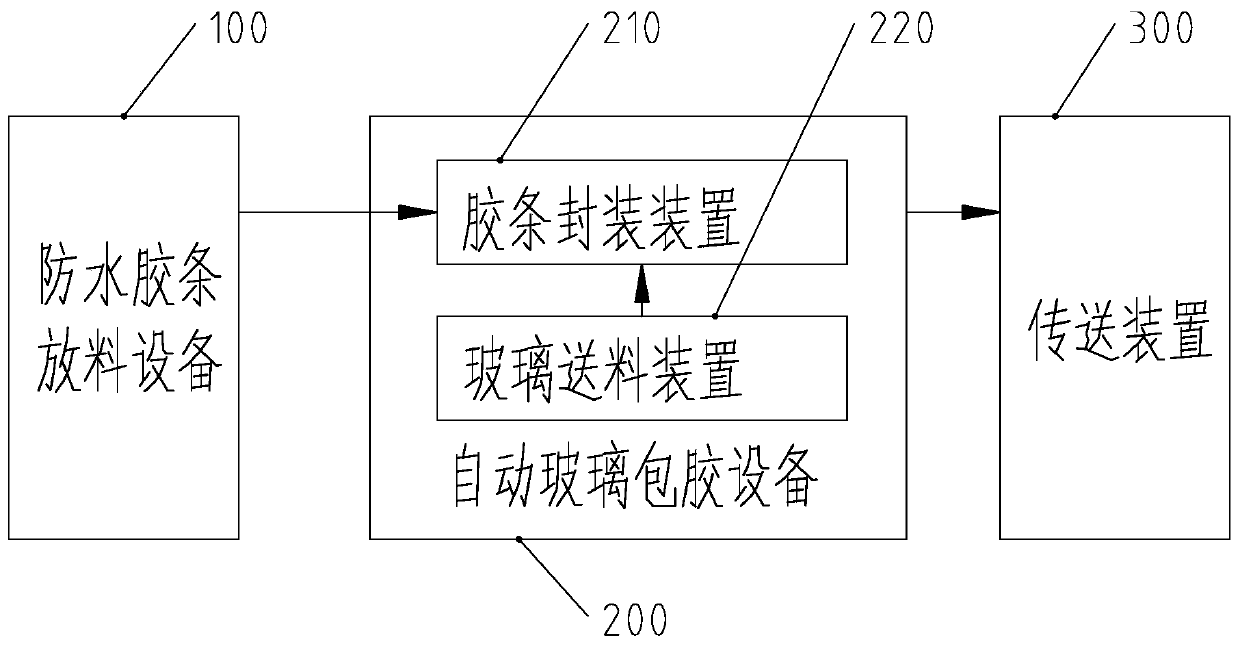

[0029] Such as figure 1 A linear wall washer waterproof strip automatic packaging system is shown, including waterproof strip discharge equipment 100, automatic glass encapsulation equipment 200 and transmission device 300 arranged in sequence, and the automatic glass encapsulation equipment includes sequentially arranged for A strip packaging device 210 for packaging waterproof strips and glass, and a glass feeding device 220 for delivering glass to the strip packaging device. The waterproof adhesive strip has a U-shaped notch. The waterproof adhesive strip is placed on the waterproof adhesive strip feeding device. The glass to be encapsulated is placed on the glass feeding device. After being processed by the automatic glass encapsulation equipment, the edge of the glass to be encapsulated is covered by the waterproof adhesive strip Wrapping becomes encapsulated strip glass.

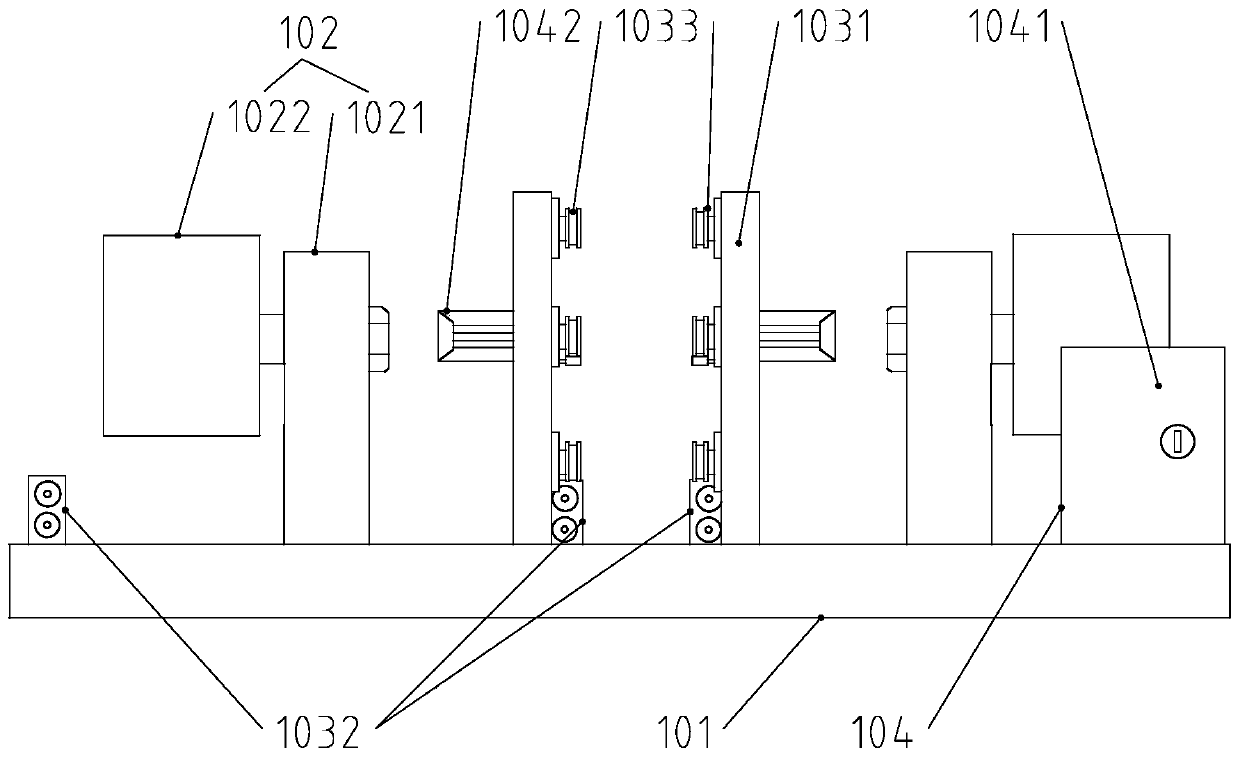

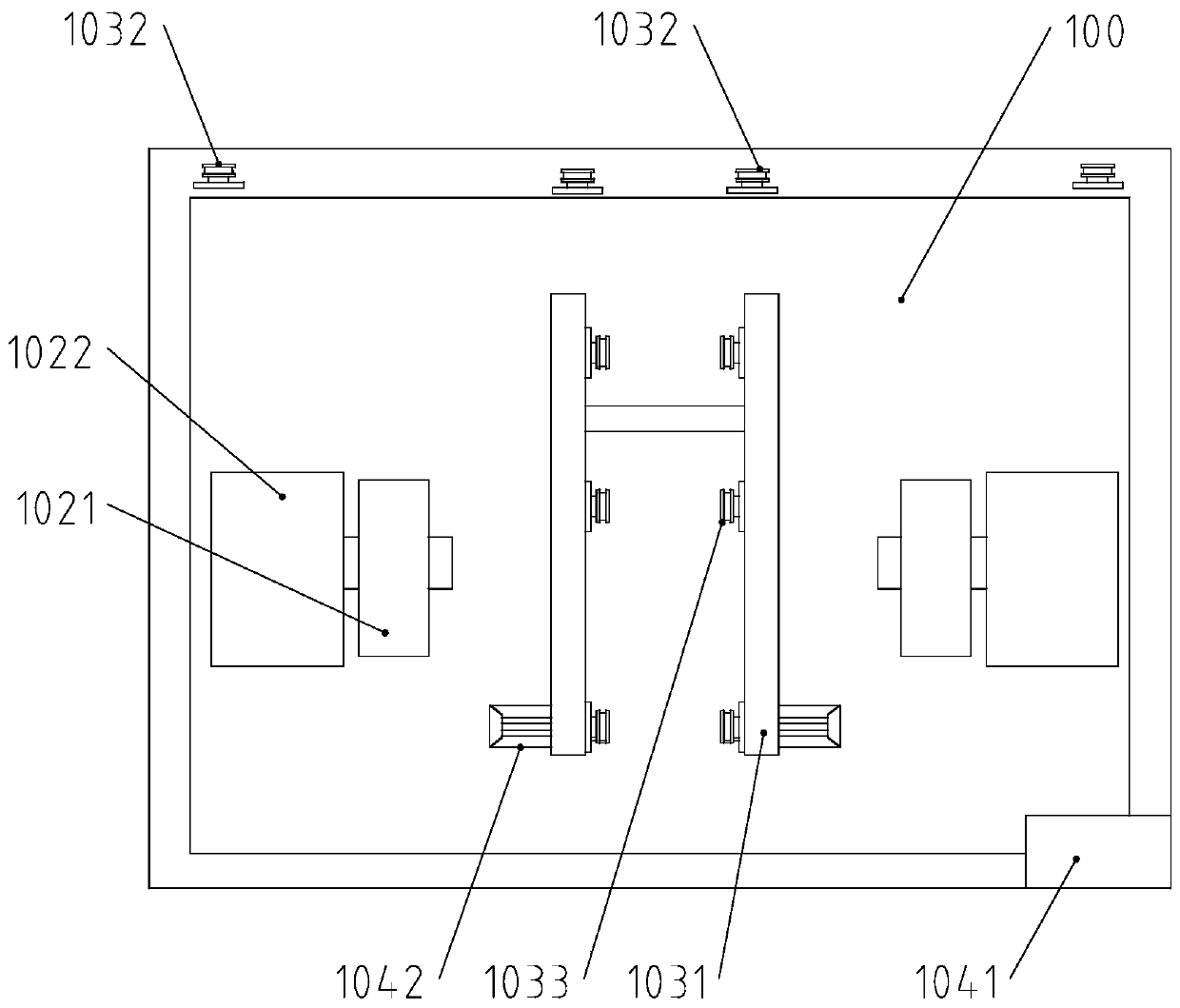

[0030] Such as figure 2 and image 3 As shown, the waterproof rubber strip discharging equipmen...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap