Automatic feeding device of charging forming machine

An automatic feeding device and forming machine technology, applied in the direction of presses, manufacturing tools, etc., can solve problems such as complex structure, flying dust, blockage failure, etc., and achieve the effects of strong anti-interference ability, reduced energy consumption, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

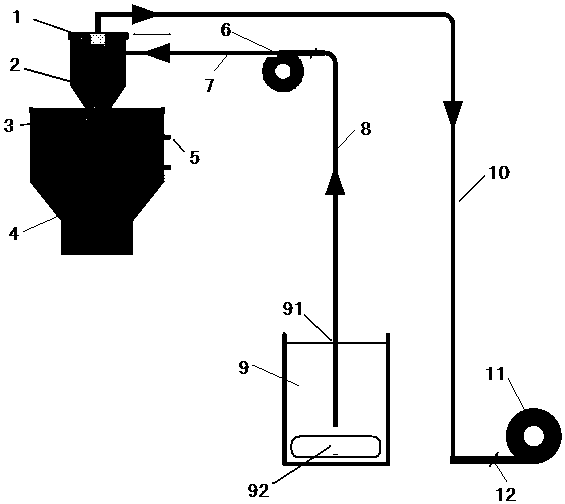

[0058] like figure 1 The automatic feeding device of the feeding molding machine shown has a mixing outlet, a lifting pipeline, a translation pipeline, an effective particle storage tank, a valve, and a blanking bin according to the flow route of the effective material. The negative pressure generating device is connected to the powder pipeline after the translation pipeline, and a secondary negative pressure generating device is arranged between the translation pipeline and the powder pipeline or on the powder pipeline; the valve is a pneumatic valve.

[0059] The vacuum or air pressure requirements generated by the first-stage negative pressure generating device, according to Mg>P 1 The principle of S>mg is determined by design; the vacuum degree or air pressure of the secondary negative pressure generating device is based on mg>P 2 S>m 0 The principle design of g determines that P 2 less than P 1 .

[0060] There are 2-3 material level sensors preset at different heigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com