Processing method for increasing printing permeability of terylene fabric

A technology of polyester fabric and treatment method, which is applied in the field of textile printing and dyeing, can solve the problems of polyester fabric printing penetration, etc., achieve the effect of small fabric strength loss, facilitate penetration, and increase printing permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

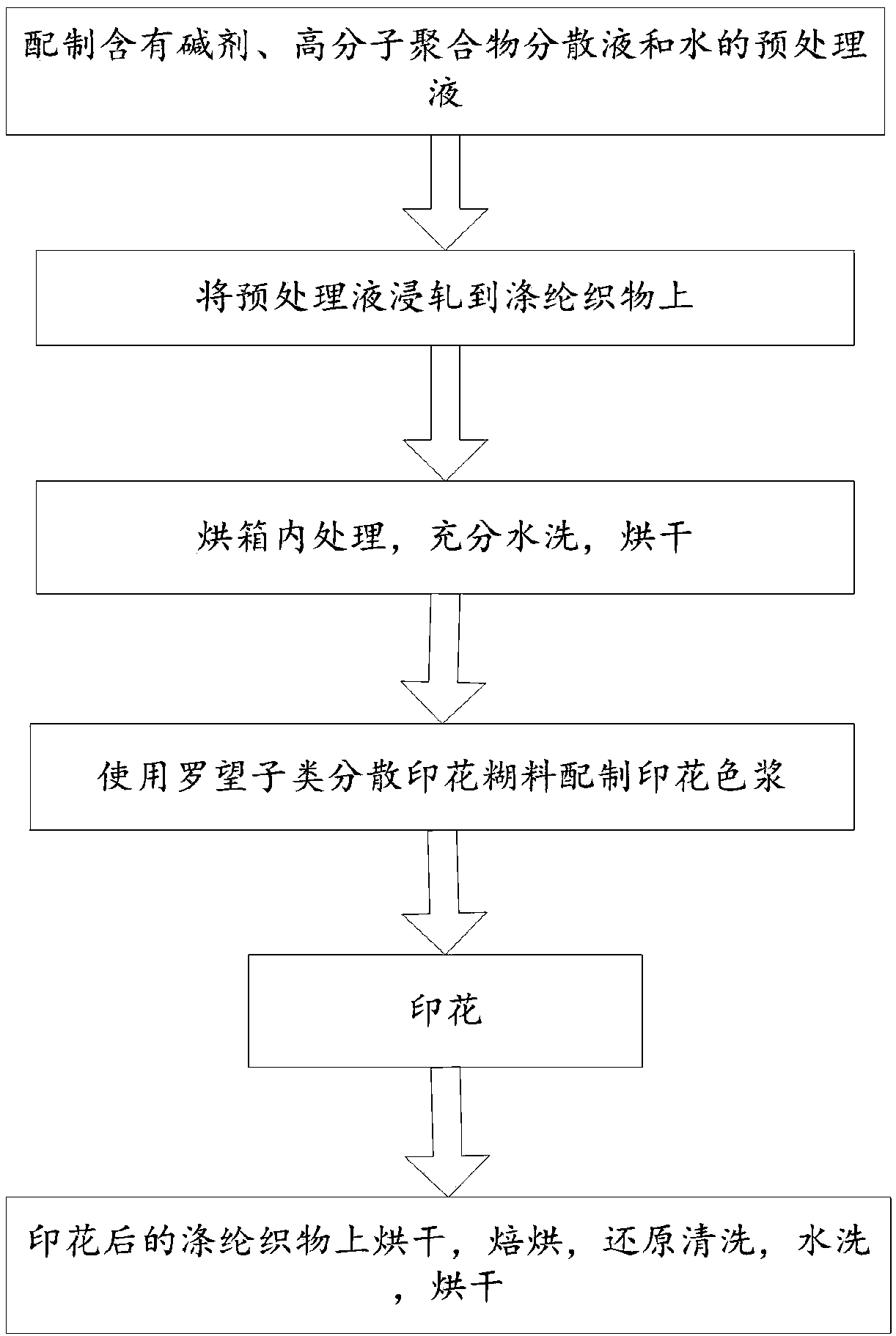

Method used

Image

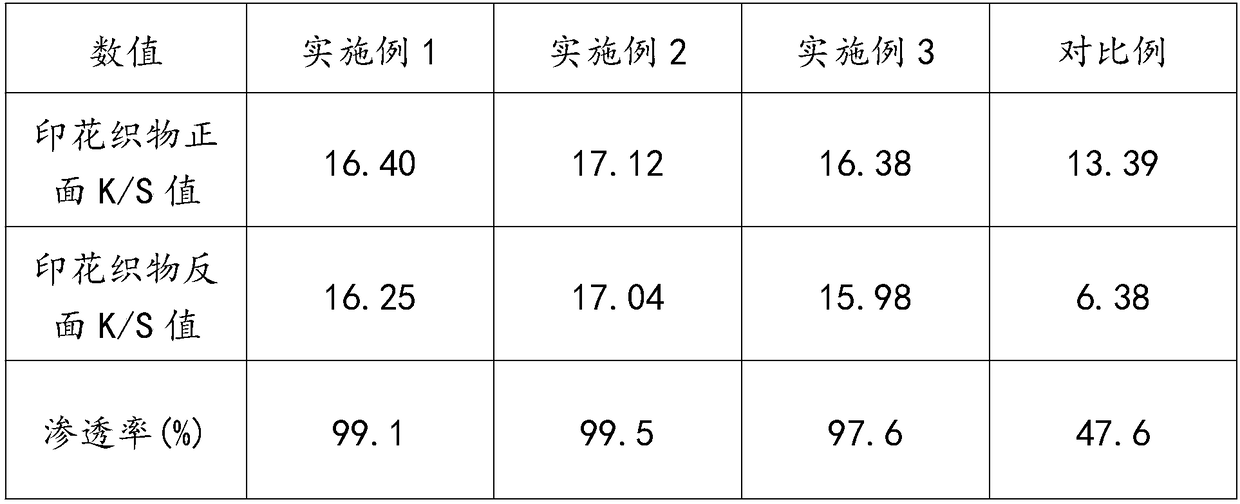

Examples

Embodiment 1

[0046] A method for improving the printing permeability of polyester fabrics, comprising the following steps:

[0047] Prepare a pretreatment solution containing alkali agent, polymer dispersion and water. The components of the pretreatment solution are as follows: sodium phosphate 60g / L, anhydrous sodium silicate 20g / L, polyester ether polymer dispersion Liquid 1g / L;

[0048] The pretreatment liquid is pad-rolled on the polyester fabric, the pressure is 0.2MPa, and the pre-treatment liquid is pad-rolled by two dipping and two-rolling methods, and the puffing rate is 74%;

[0049] The above-mentioned polyester fabric after padding was placed in an oven for treatment at a baking temperature of 125°C for 9min, washed twice with hot water with a hardness of 9mg / L, washed twice with cold water, and dried at 85°C.

Embodiment 2

[0051] A method for improving the printing permeability of polyester fabrics, comprising the following steps:

[0052] Prepare the pretreatment liquid containing alkaline agent, high molecular polymer dispersion and water. The contents of each component of the pretreatment liquid are as follows: sodium phosphate 70g / L, sodium phenate 20g / L, polyester ether high molecular polymer dispersion 2.5g / L;

[0053] Pad the pretreatment solution onto the polyester fabric at a pressure of 0.1 MPa, and pad the pretreatment solution by two dips and two pads, with a rate of 80%;

[0054] The polyester fabric after padding was placed in an oven for 10 minutes at a baking temperature of 130°C, washed twice in hot water with a hardness of 9 mg / L, twice in cold water, and dried at 85°C.

Embodiment 3

[0056] A method for improving the printing permeability of polyester fabrics, comprising the following steps:

[0057] Prepare the pretreatment liquid containing alkaline agent, high molecular polymer dispersion liquid and water, the contents of each component of the pretreatment liquid are as follows: sodium phosphate 50g / L, sodium formate 15g / L, polyester ether high molecular polymer dispersion liquid 5g / L ;

[0058] The pretreatment liquid is pad-rolled on the polyester fabric, the pressure is 0.3MPa, and the pre-treatment liquid is pad-rolled in the mode of two dipping and two rolling, and the puffing rate is 66%;

[0059] The polyester fabric after padding was placed in an oven for 11 min at a baking temperature of 135°C, washed twice with hot water with a hardness of 8 mg / L, twice with cold water, and dried at 85°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com