Mechanism for detecting automobile fitting

A technology of auto parts and racks, which is applied in the field of detection, can solve the problems such as the inability to detect auto parts, and achieve the effects of wide application range, improved reliability and stable clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Further detailed explanation through specific implementation mode below:

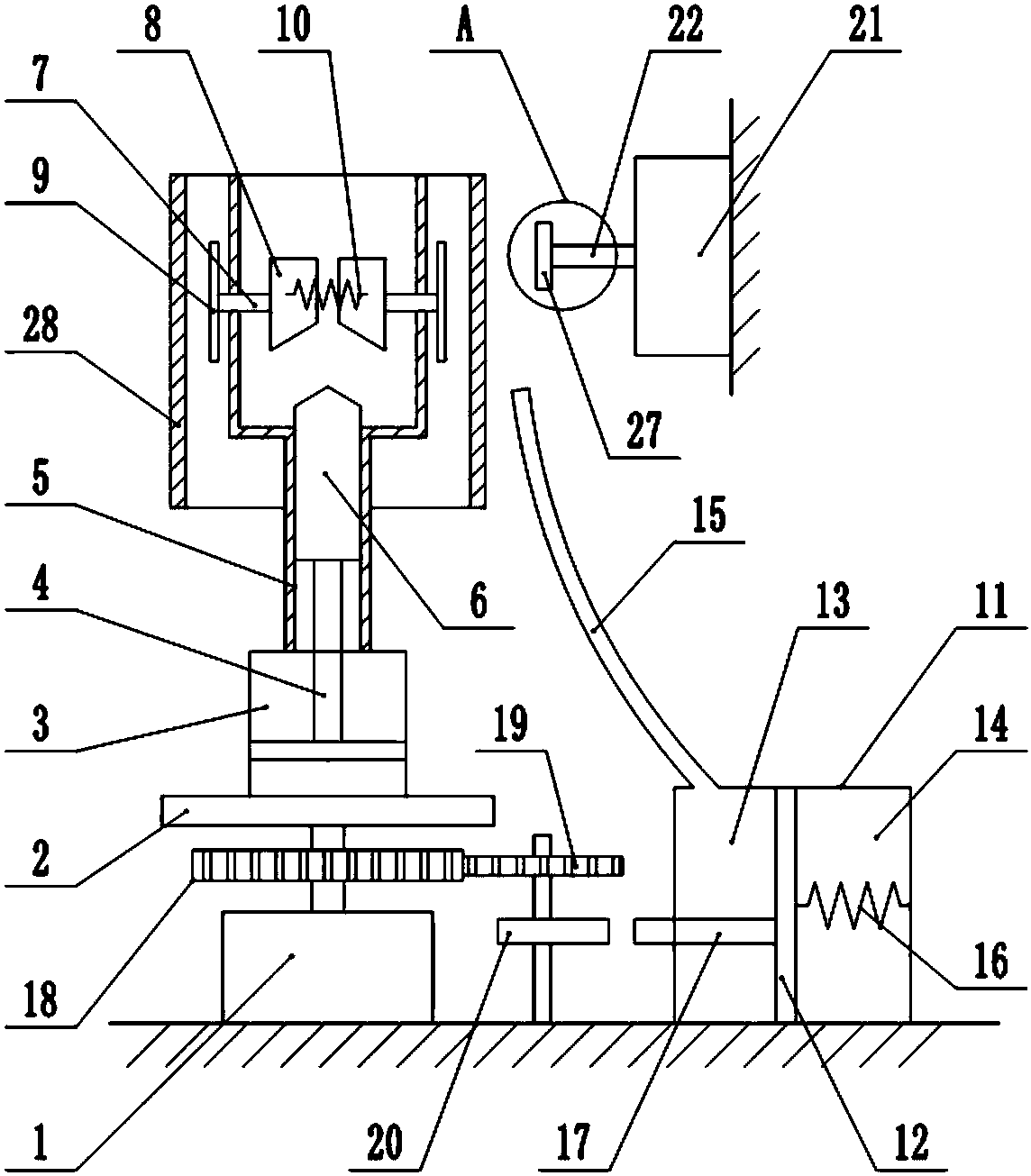

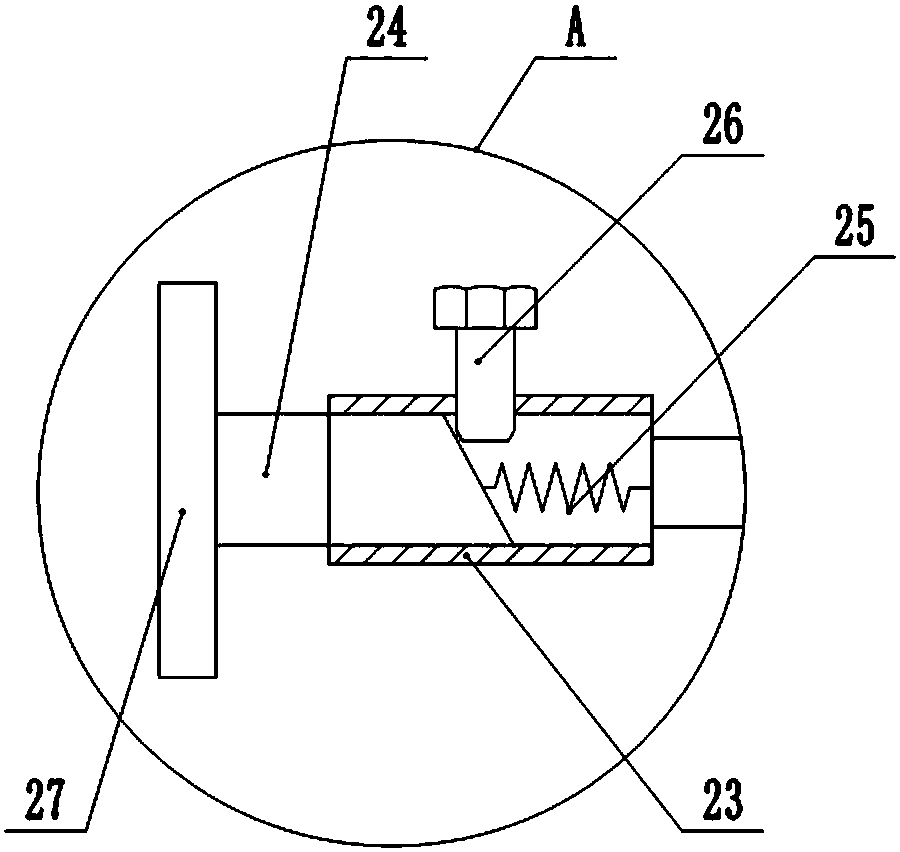

[0021] The reference signs in the drawings of the description include: the first stepper motor 1, the rotating plate 2, the telescopic cylinder 3, the first piston rod 4, the vertical shaft 5, the slider 6, the slider 7, the first wedge 8, the clip Holder 9, first spring 10, cylinder body 11, second piston 12, left chamber 13, right chamber 14, intake pipe 15, third spring 16, second piston rod 17, first gear 18, second Gear 19, cam 20, second stepping motor 21, telescopic part 22, cylinder 23, second wedge block 24, second spring 25, bolt 26, friction plate 27, workpiece 28.

[0022] This embodiment is basically as figure 1 As shown, the mechanism that can detect auto parts includes a frame, the frame is fixedly installed with a first stepping motor 1 and a cylinder body 11, the first stepping motor 1 is fixedly connected with an output shaft, and the output shaft is fixedly connected with a ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com