Energy-saving horizontal-type sterilizing pot

A sterilizer, horizontal technology, applied in the field of energy-saving horizontal sterilizers, can solve the problems of poor sterilization effect, uneven and rapid cooling, cumbersome feeding and discharging, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

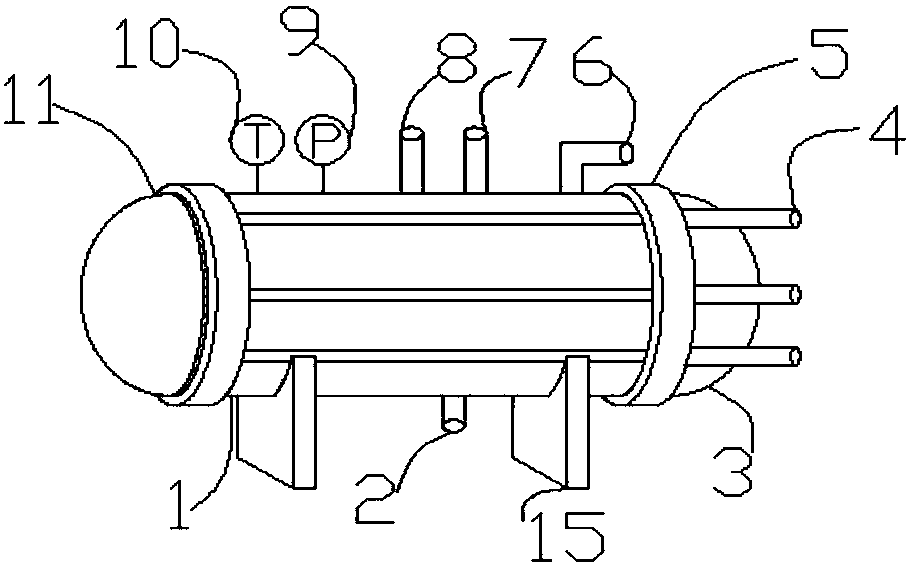

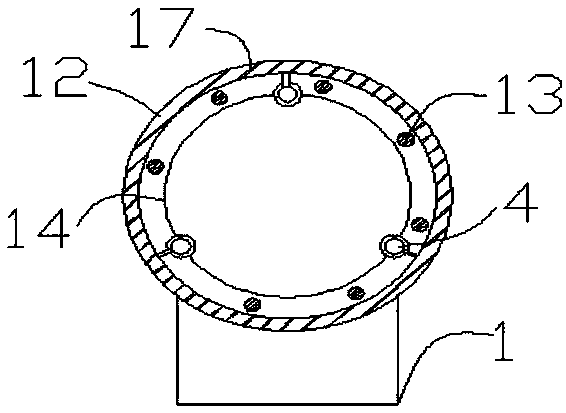

[0019] Embodiment 1: with reference to attached figure 1 and 2 As shown, an energy-saving horizontal sterilizing pot mainly includes a pot body 1, a front cover 11 and a rear cover 3. A heating layer 12 is connected to the inner side of the pot body 1, and a plurality of A water spray pipe 13, a plurality of hydraulic rods 4 are fixed in the pot body 1, a spiral resistance wire is installed in the heating layer, the spiral resistance wire in the heating layer can heat the pot evenly and rapidly, and the Multiple water spray pipes can quickly and evenly cool down the pot.

[0020] Refer to attached figure 1 As shown, the pot body 1 is equipped with an air inlet pipe 7, a liquid inlet pipe 8, a pressure gauge 9 and a thermometer 10, and the lower end of the pot body 1 is connected with a drain pipe 2 and a base 15. 1 is equipped with reinforcing ring 5, pressure gauge and thermometer can show the situation in the pot to be convenient to control.

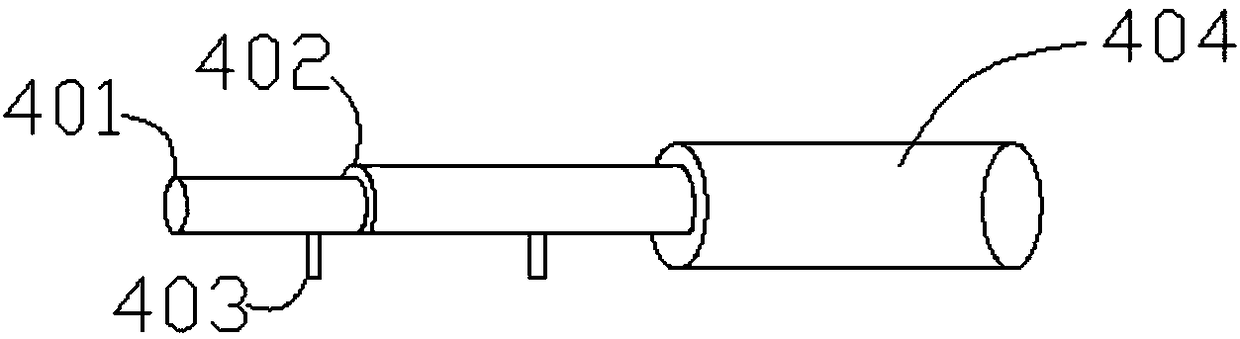

[0021] Refer to attached ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com