Tea screening machine

A sieving machine and tea technology, which are applied in the directions of sieving, solid separation, tea treatment before extraction, etc., to achieve the effect of improving work efficiency and good tea quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

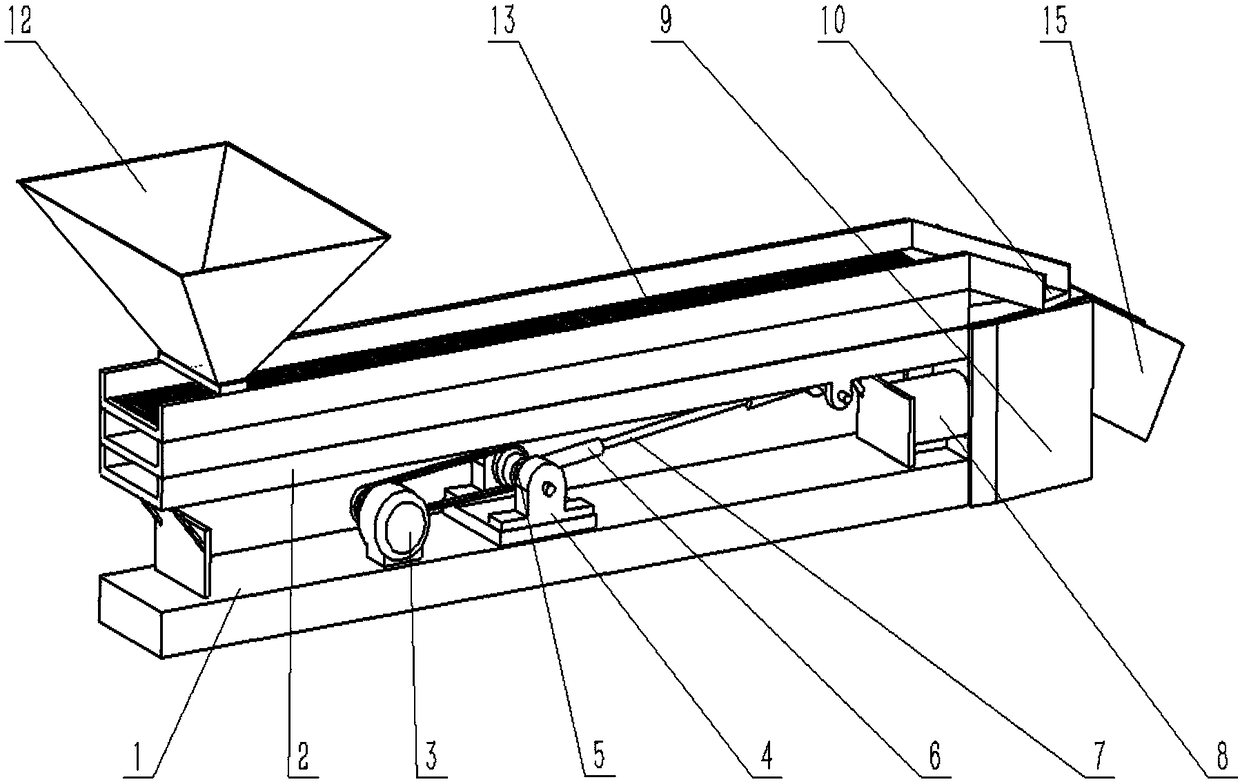

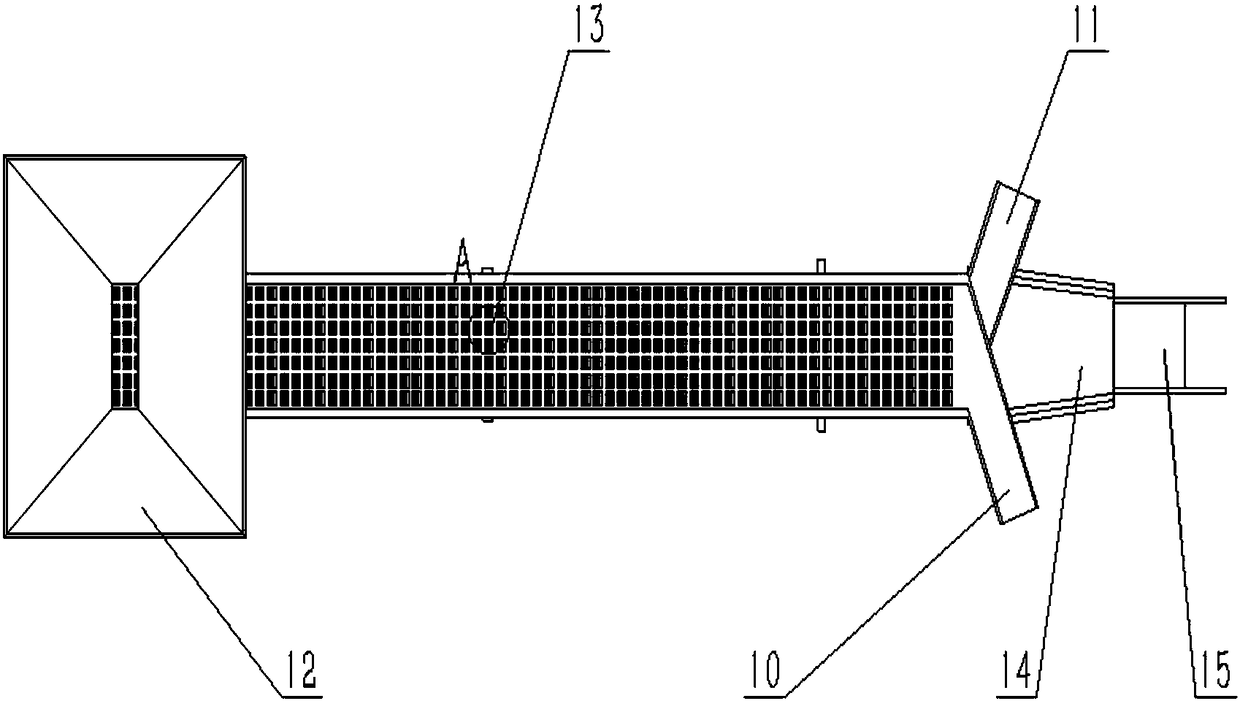

[0017] A kind of tea screening machine of the present invention is described further in conjunction with accompanying drawing.

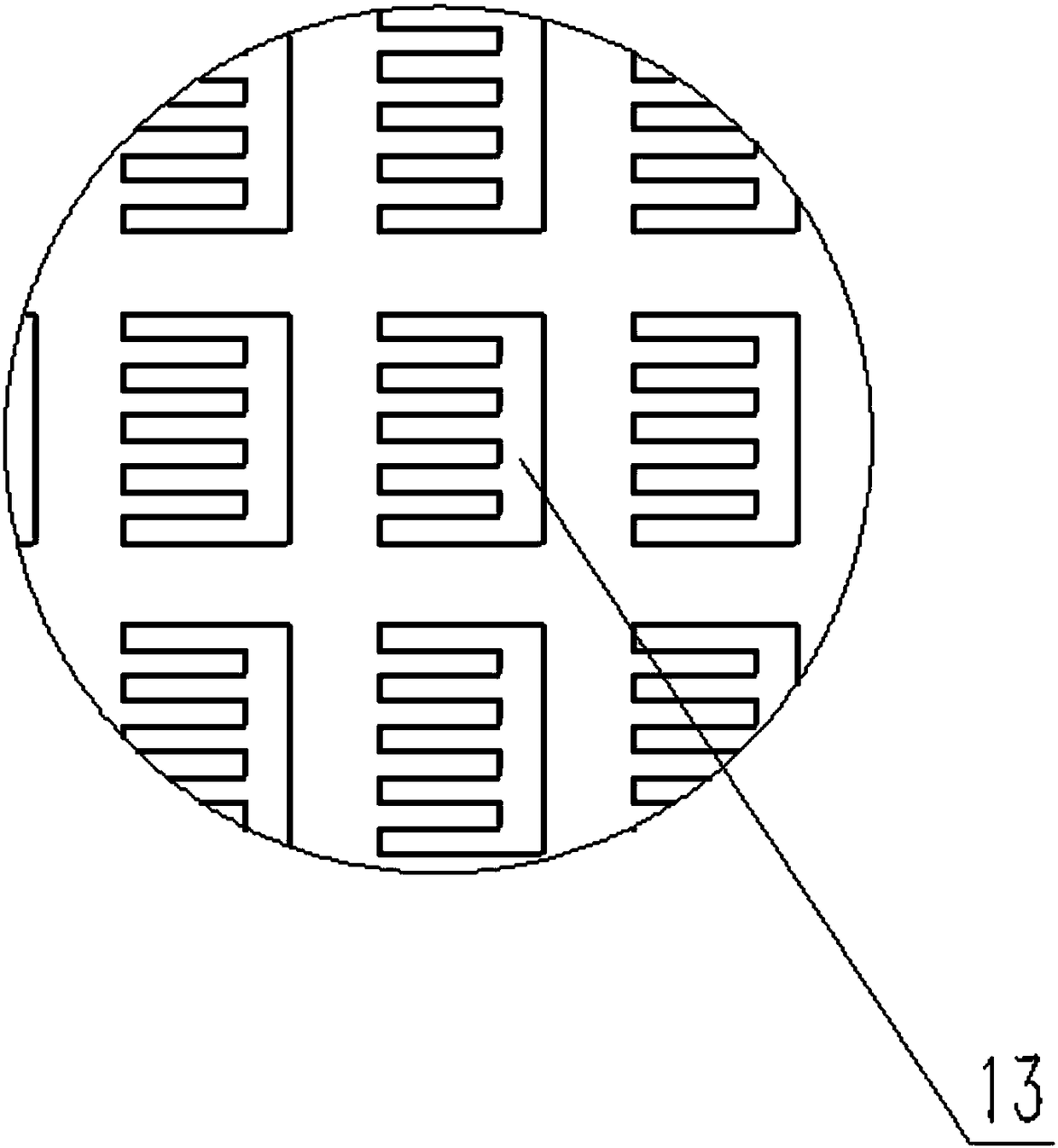

[0018] As shown in the accompanying drawing, it is a kind of tea screening machine, which includes a first base 1, and a screening plate 2 is fixed above the first base 1. The screening plate 2 is divided into upper, middle and lower layers, and each layer of screening plate 2 A plurality of screening holes 13 are formed on the top, one end of the upper screening plate is fixed with a discharge hopper 12, and the other end is fixed with a first discharge trough 10, and the middle screening plate and the lower screening plate face the first discharge chute One end of 10 is respectively fixed with the second discharge trough 11, the third discharge chute 14, and a power device is arranged between the lower screening plate and the first base 1, and the power device includes a motor 3, two second bases 4, The motor 3 and the two second bases 4 are fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com